Nio starts series production of its 900-volt drive system

The EV9 is a 5.33-metre-long mix of SUV and luxury saloon. The first model based on the 900-volt platform will be delivered from the first quarter of 2025, but can already be pre-ordered at prices starting at 800,000 yuan or around 100,000 euros. It is fitted with a 120 kWh battery made from self-developed round cells in 46105 format with an energy density of 292 Wh/kg. With a corresponding charging station, the battery can be charged with 5C, i.e. 600 kW. Recharging for a range of 255 kilometres (in CLTC) thus takes five minutes.

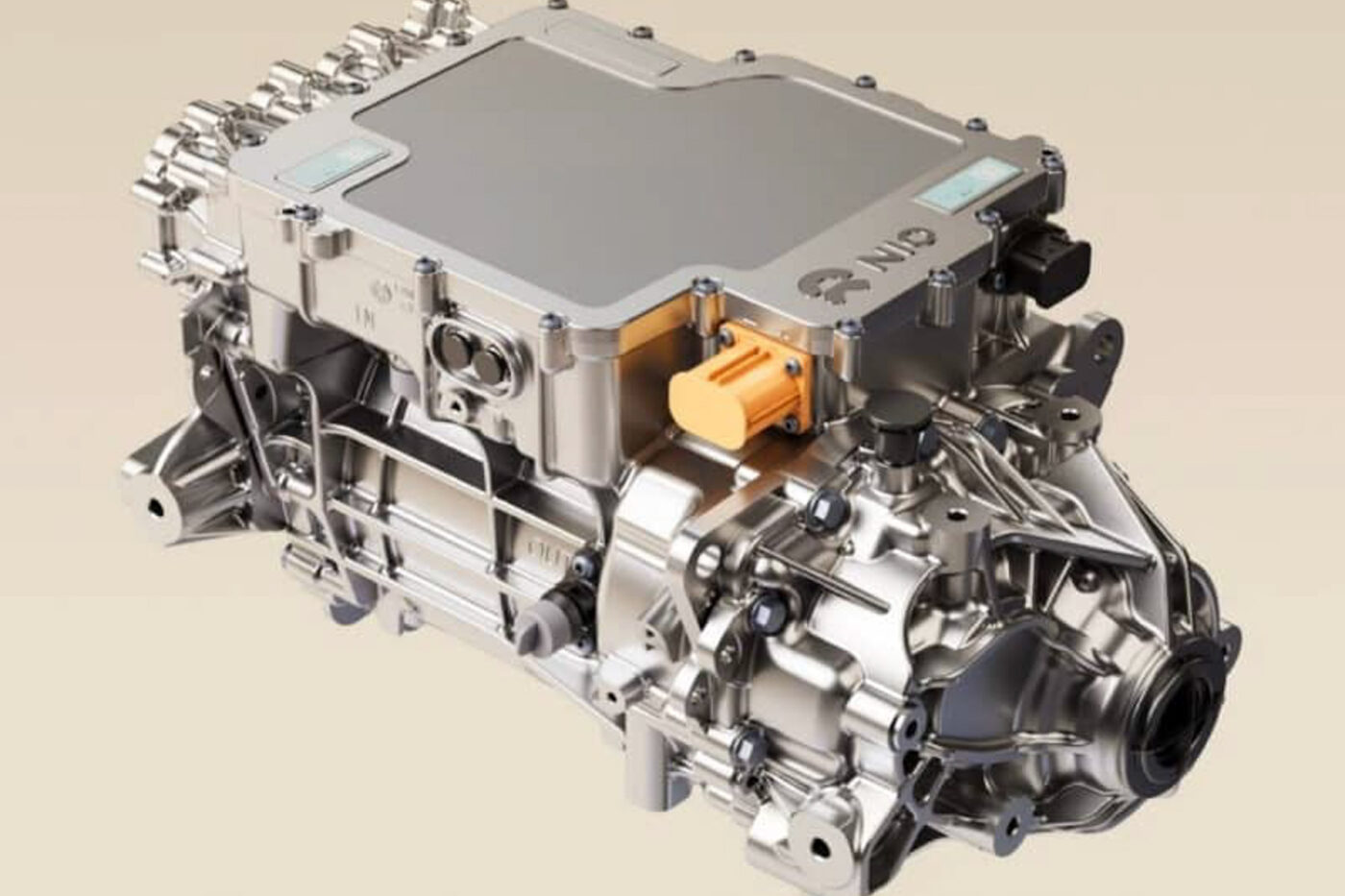

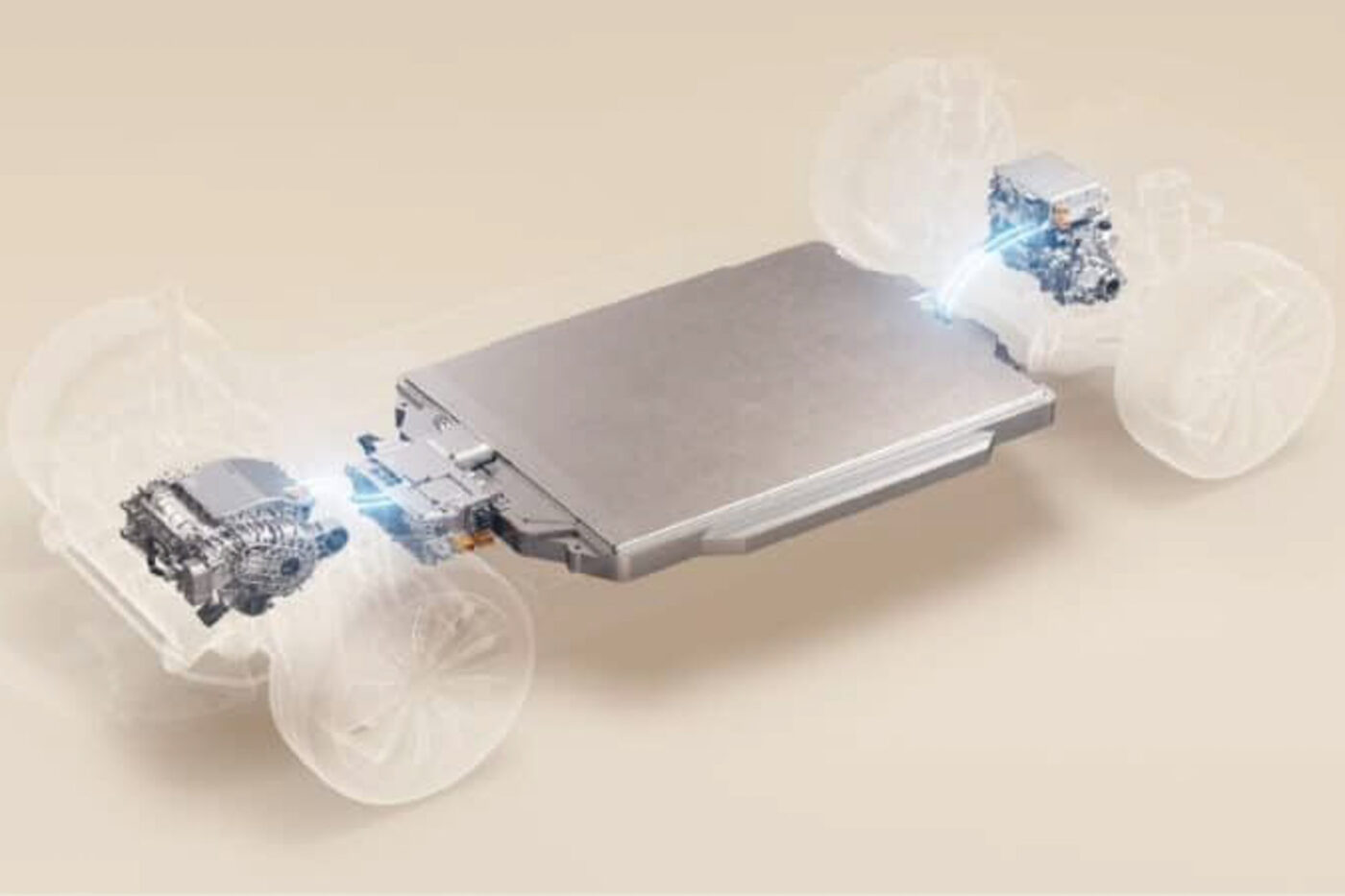

Nio is relying on all-wheel drive for the upcoming top model. A permanent magnet synchronous motor with 340 kW is installed on the rear axle, while a 180 kW asynchronous motor is used at the front. The system output will be 520 kW. As the degree of integration of the 900-volt electric drives was increased compared to Nio’s previous EVs, among other things, they will be 30 per cent lighter and 280 millimetres shorter than their predecessors.

The reduction in installation space will provide more space in the interior, while the lower weight should reduce energy consumption, according to Nio. For example, the PSM on the rear axle will only weigh 79 kilograms and achieve a power density of 4.3 kW/kg. For the asynchronous motor, Nio specifies a power density of 2.6 kW/kg, which corresponds to a weight of 69 kilograms. According to Nio, this is the “world’s highest power density among asynchronous electric motors” – this cannot currently be verified.

The higher peak output of 340 kW at the rear axle – a current Nio ET5 with two motors achieves a system output of 360 kW – will be possible thanks to a revised cooling system for the drive unit. As a result, the peak continuous output of the engine will be increased by 30 per cent.

Both the PSM at the rear and the ASM at the front are controlled by new power electronics. These rely on silicon carbide semiconductors and thus achieve a power density of 1,315 kW/l, according to Nio. The system is designed for over 300,000 power cycles.

The news of the start of production for the 900-volt drive comes at the same time as an anniversary. Nio has produced a total of one million electric drives to date.

0 Comments