Marelli receives major order for battery cooling plate

The order comprises various vehicle platforms and segments for the Chinese, North American and European markets, according to Marelli. As is usually the case in the industry, the customer in question is not named in the press release. In view of the high unit volumes, the multiple platforms and the different markets, only large corporations such as the Volkswagen Group, Stellantis or General Motors come into question.

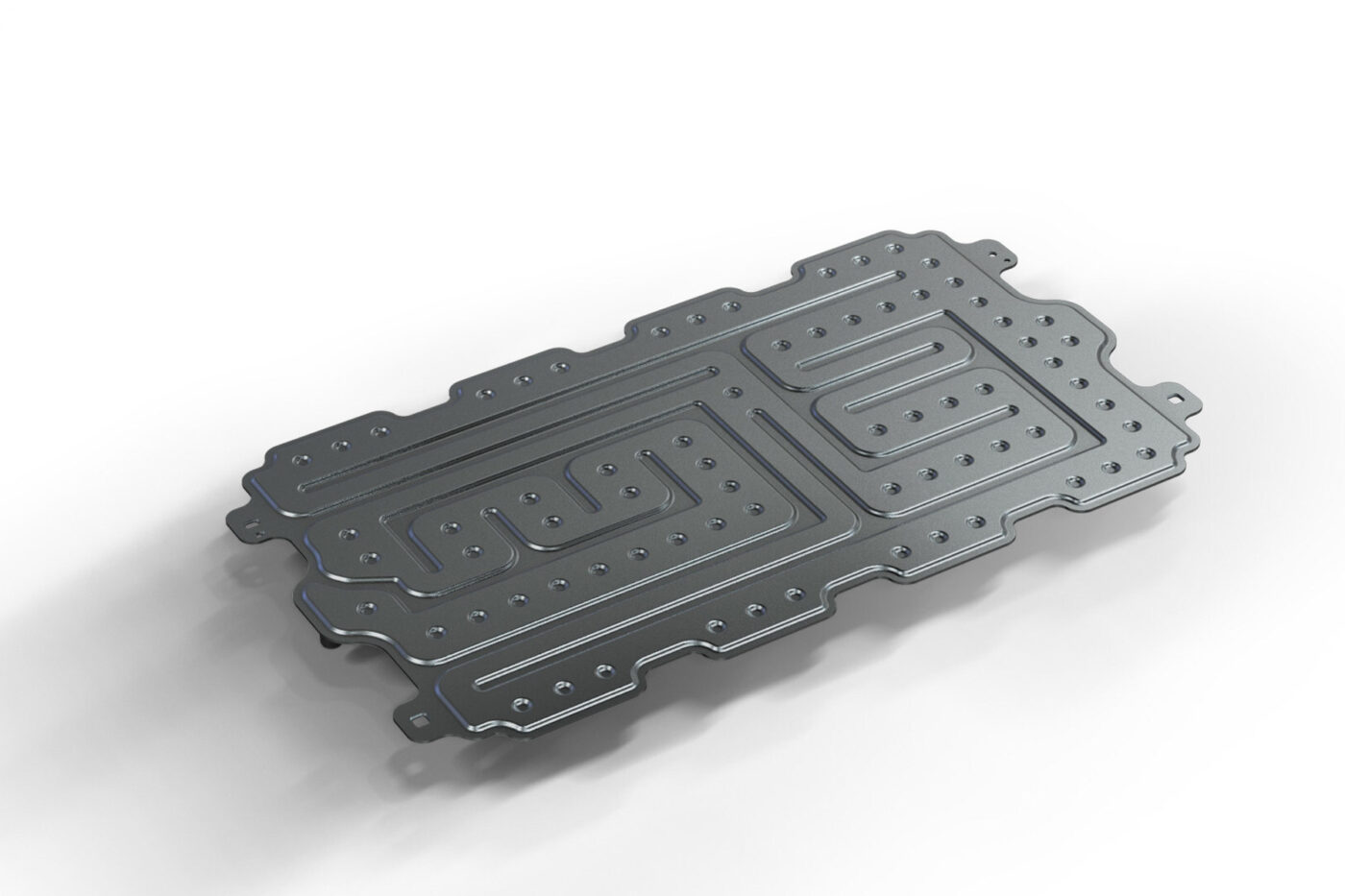

Marelli’s Battery Thermal Plate is a component of the battery’s thermal management system. The plate, which the supplier claims to be ‘extremely flat’, is placed at the bottom of the battery housing, with the battery cells or modules then sitting on the cooling plate. The special ‘dot dimples’ design, which are specifically positioned indentations, is intended to optimise heat exchange between the cells and the plate. “Thanks to specific paths of the thermal flows, this solution stabilizes the temperature of the battery cells and provides excellent temperature uniformity,” Marelli wrote. And because the Battery Thermal Plate is so flat, there is more space in the battery housing for the cells and integration is also easier.

The ‘Dot Dimples’ should also be able to be quickly customised ‘to the needs of each customer for different battery types and geometries’. This means that not only small or extra-large formats are possible, but the cooling behaviour can also be adapted to the respective battery. Marelli maintains test laboratories and simulation capacities in its global development centres for this purpose. Production is to take place close to the three main markets, specifically in China, Mexico and Romania for Europe.

The thermal management of a battery in an electric car is very important. Thermal management has an impact on battery life, the range of the vehicle, the performance of the drive system and the fast-charging capability. Regardless of the outside temperature and usage, the battery must remain within the optimum temperature range in order to deliver the required performance. In addition, the energy consumption of the thermal management system (whether for the battery or the interior) is an important factor in the overall consumption of the vehicle – and therefore the range.

“We are proud of this important assignment, which further strengthens our collaboration with global carmakers on technologies that are key to optimizing thermal energy management of vehicles,” said Shuji Kobayashi, President of Marelli’s Green Technology Solutions division. “Through our solid experience and comprehensive portfolio, we support OEMs in achieving the most efficient solutions for electric, hybrid and internal combustion engine vehicles, adapting to their specific needs to co-create with our customers their vehicles of tomorrow.”

0 Comments