Paraclete Energy to halve battery weight and double range

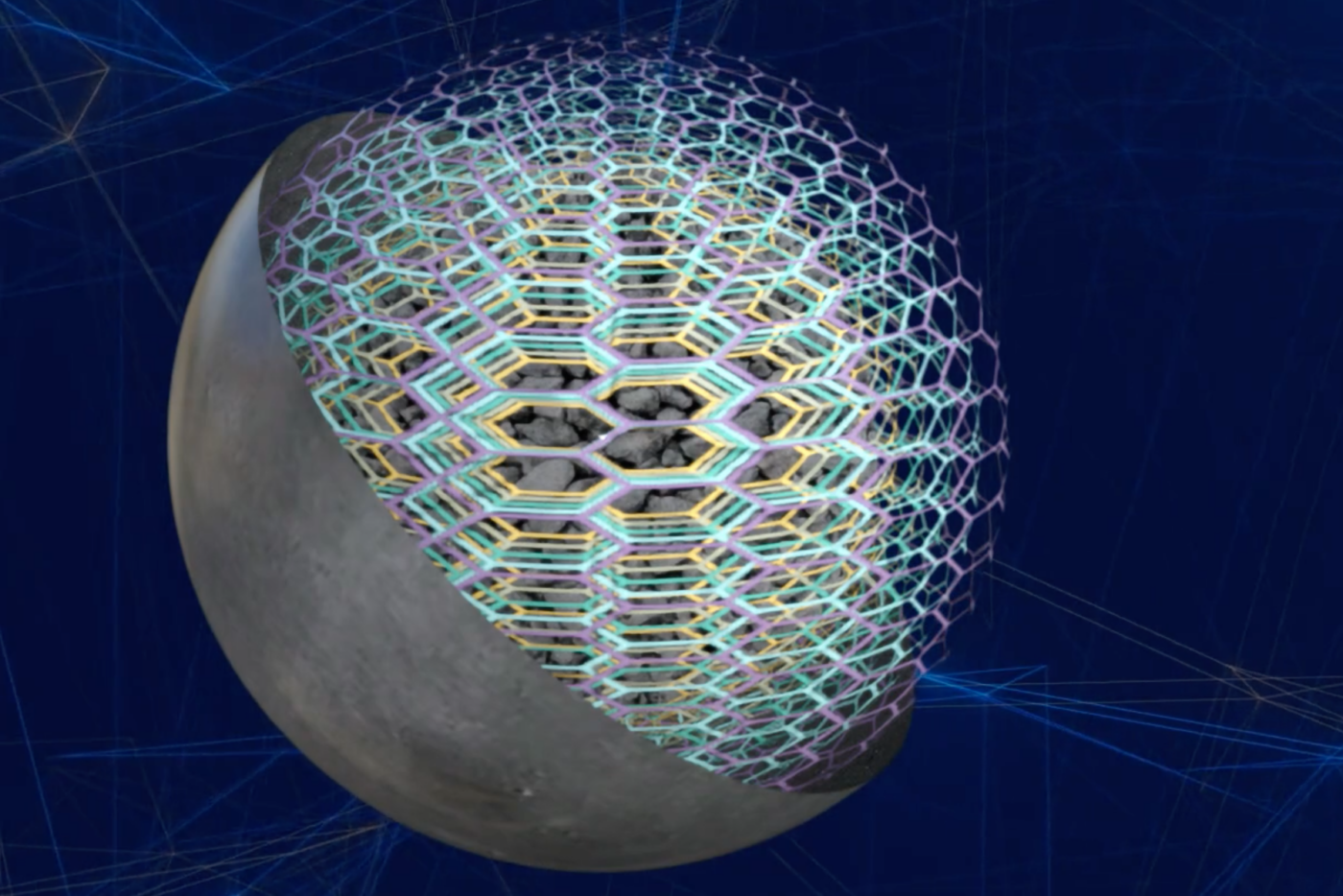

The anode material, which is based on silicon and utilises a polymer matrix approach, was presented in more detail in August by the battery material specialist based in the US state of Michigan. At that time, it was stated that SILO Silicon was significantly cheaper than conventional graphite anodes. The cost of SILO Silicon would only be 35 US dollars per kilowatt hour, compared to 53 US dollars per kWh for graphite anodes. Paraclete Energy is now following up with the study, which highlights further advantages of the material.

“As a company dedicated to pushing the boundaries of battery innovation, our latest study underscores SILO Silicon’s potential to redefine the EV landscape,” says Jeff Norris, CEO of Paraclete Energy. “Our data-driven approach demonstrates not only substantial reductions in battery weight and size but also a remarkable increase in driving range. These advancements address critical consumer demands for more efficient, affordable, and sustainable electric vehicles.”

According to the company’s own study, which cannot be independently verified for the time being, the use of SILO Silicon should enable the reduction of a standard 80 kWh battery pack from around 7,000 individual battery cells weighing 565 kg to less than 2,000 batteries weighing just 150 kg. This is not just a halving of the weight, but a reduction of 73 per cent. In addition, a 300 kg battery configuration with SILO Silicon delivers 160 kWh of power, doubling the standard range from 290 miles (466 kilometres) to over 580 miles (932 kilometres), while the battery weight is still almost 50 per cent lower than the original configuration.

0 Comments