ZF unveils new eTRAC drive for medium to large construction machines

With the eTRAC series, ZF targets a broad range of applications in the construction industry – from compact construction site loaders to heavy wheel loaders. According to the developers, the system’s modular architecture allows for integration into different vehicle platforms. The supplier states that the drive system has a power range of 20 to 230 kW. The newly presented eTRAC solution, called eCD110-230, covers the upper application ranges. The system was largely developed at ZF in Friedrichshafen, with series production to take place at the ZF site in Passau.

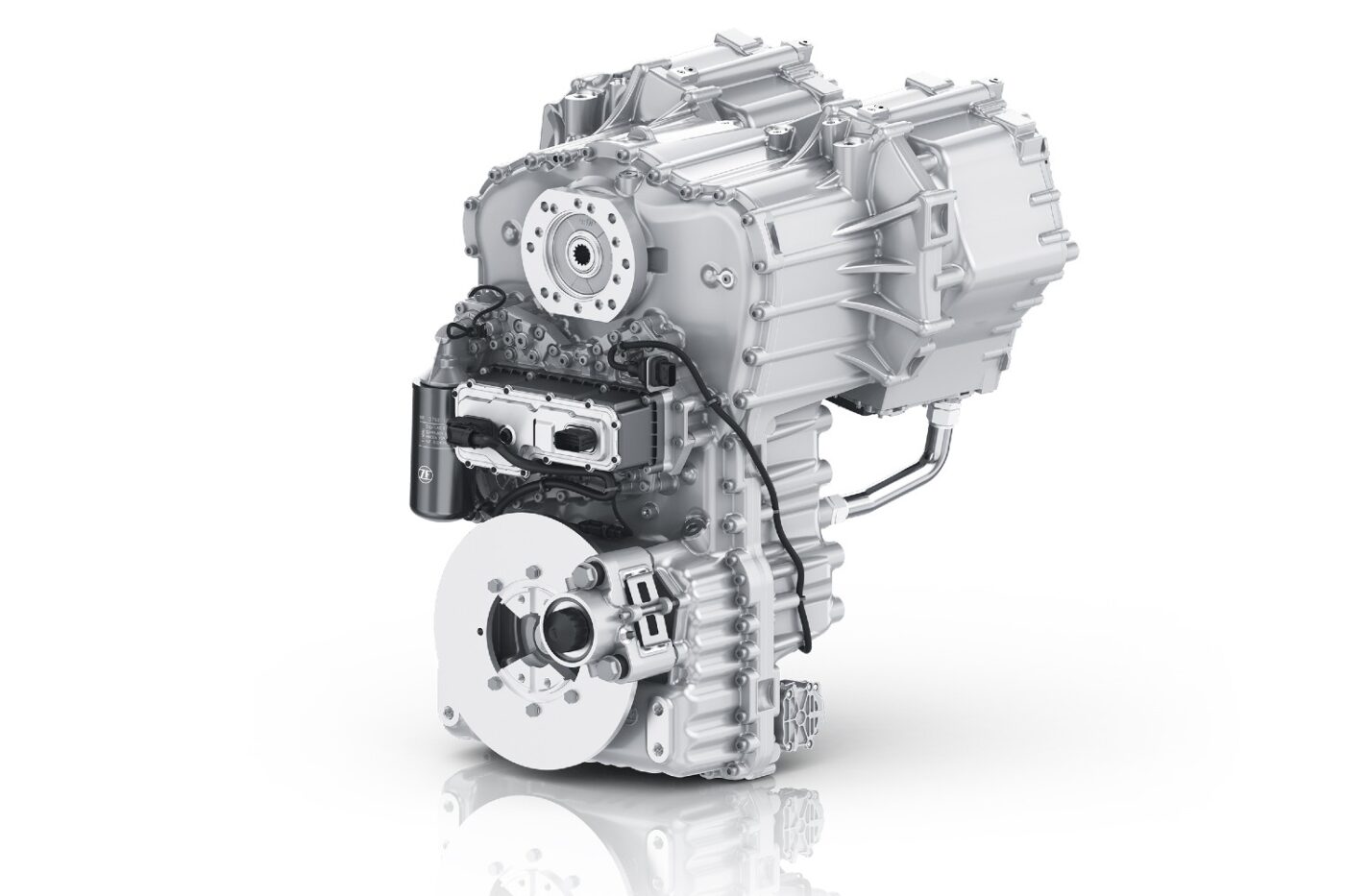

The new central drive consists of newly developed electric motors, an electric power takeoff, or ePTO, a control unit for the overall system performance and an energy management system. With an operating voltage of 650 volts, the solution can be scaled up to 120 kW continuous power output, according to ZF.

The ePTO included in the system offers a continuous power output of 30 to 70 kW. As ZF explains, the latest addition to the eTRAC family not only reduces emissions and maintenance compared to conventional combustion engines, but also opens up new possibilities in vehicle architecture – ‘for example, by integrating intelligent control units and braking systems’.

In addition to the new drive presented at Bauma, there are already electric sister systems eCD50, eCD70 and eCD90 for small to medium-sized construction machines. All these solutions can be installed in both battery-powered and fuel-cell-powered construction machines.

At the trade fair, ZF presented the CeTrax 2 and CeTrax 2 dual electric central drives for construction site trucks and special vehicles. They are based on ZF’s modular electric drive platform for heavy commercial vehicles and, according to the developers, are also suitable for platforms initially designed as combustion engine vehicles. “It enables cost-effective conversion with comparatively little development effort,” the supplier emphasised. The system includes either one or two oil-cooled PSM electric motors with hairpin winding and 800-volt SiC inverter.

‘Bauma is an important opportunity for us to showcase what is technologically possible – and how deeply rooted ZF is in the region,” said Andreas Moser, head of ZF’s Industrial Technology division and site manager in Passau. “Our solutions combine mechanical expertise with digital intelligence.” And many of the technologies that ZF is presenting at Bauma were developed not far away in Friedrichshafen.

Incidentally, ZF also presented innovations for conventional combustion engines in Munich: “Even though ZF is pursuing the goal of making construction and special vehicles completely emission-free, diesel engines will continue to dominate the market and the industry for a long time to come,” said Ralf Boss, head of the Special Vehicle Systems Product Line. “We are constantly developing our products further and thus mastering current and future challenges.”

Incidentally, supplier Schaeffler also presented a new 800-volt electric motor series for electric and hybrid drive systems at Bauma.

press.zf.com, press.zf.com (CeTrax 2 and CeTrax 2 dual; both in German), press.zf.com (eTrac; in German)

0 Comments