Dürr and Grob present battery concept factory

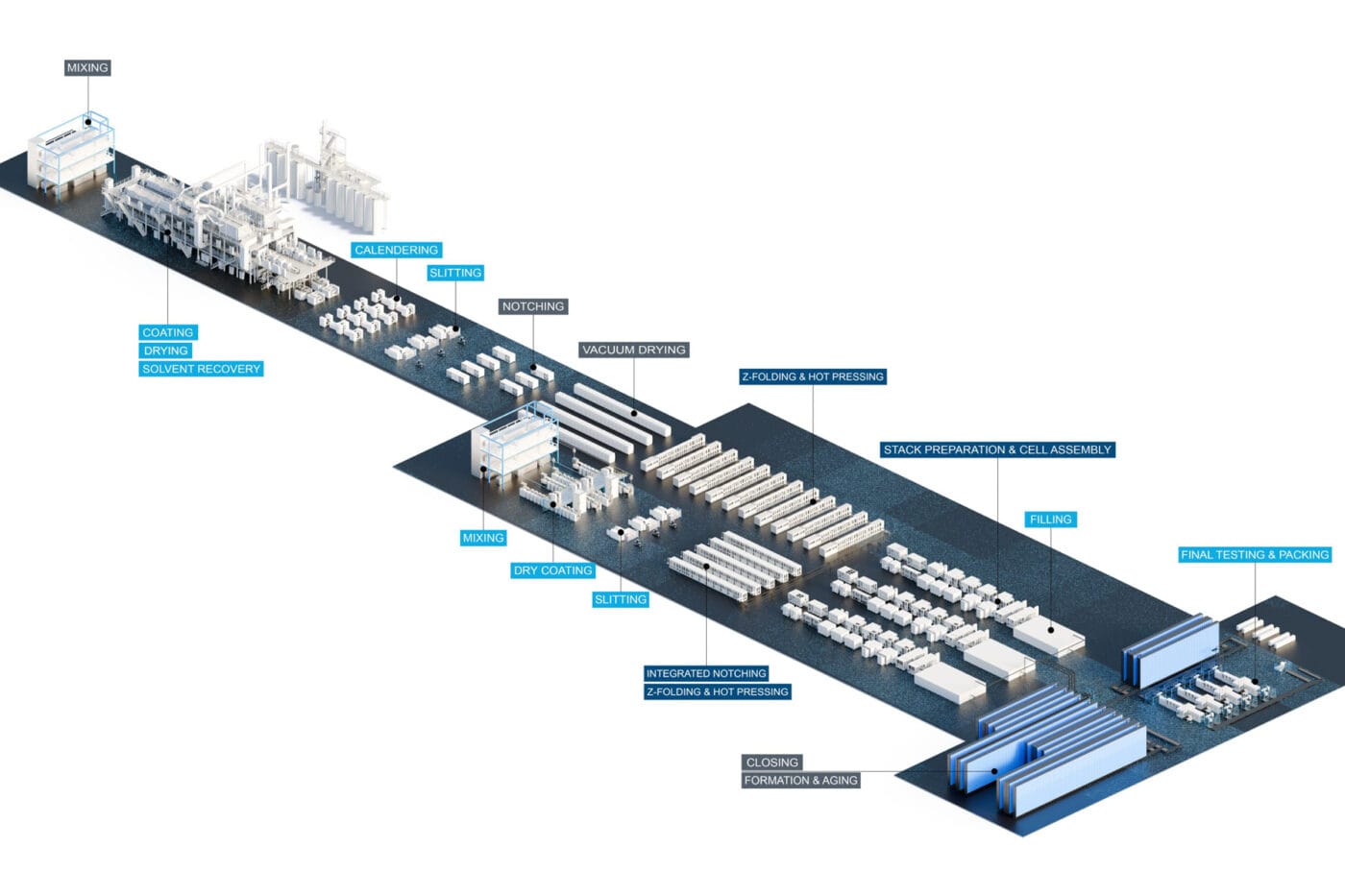

Dürr and Grob want to demonstrate several technical innovations with the concept factory. Key technologies include dry coating of the electrodes, which does not require a drying process, and high-performance Z-folding technology for cell assembly with integrated notching, according to the two companies.

Dürr and Grob have been cooperating since 2022 to establish themselves as a system provider of battery production systems in Europe and North America. The mechanical engineering company Manz was previously also part of this German battery production alliance, but with Manz’s insolvency, Dürr and Grob have decided to continue their projects as a duo.

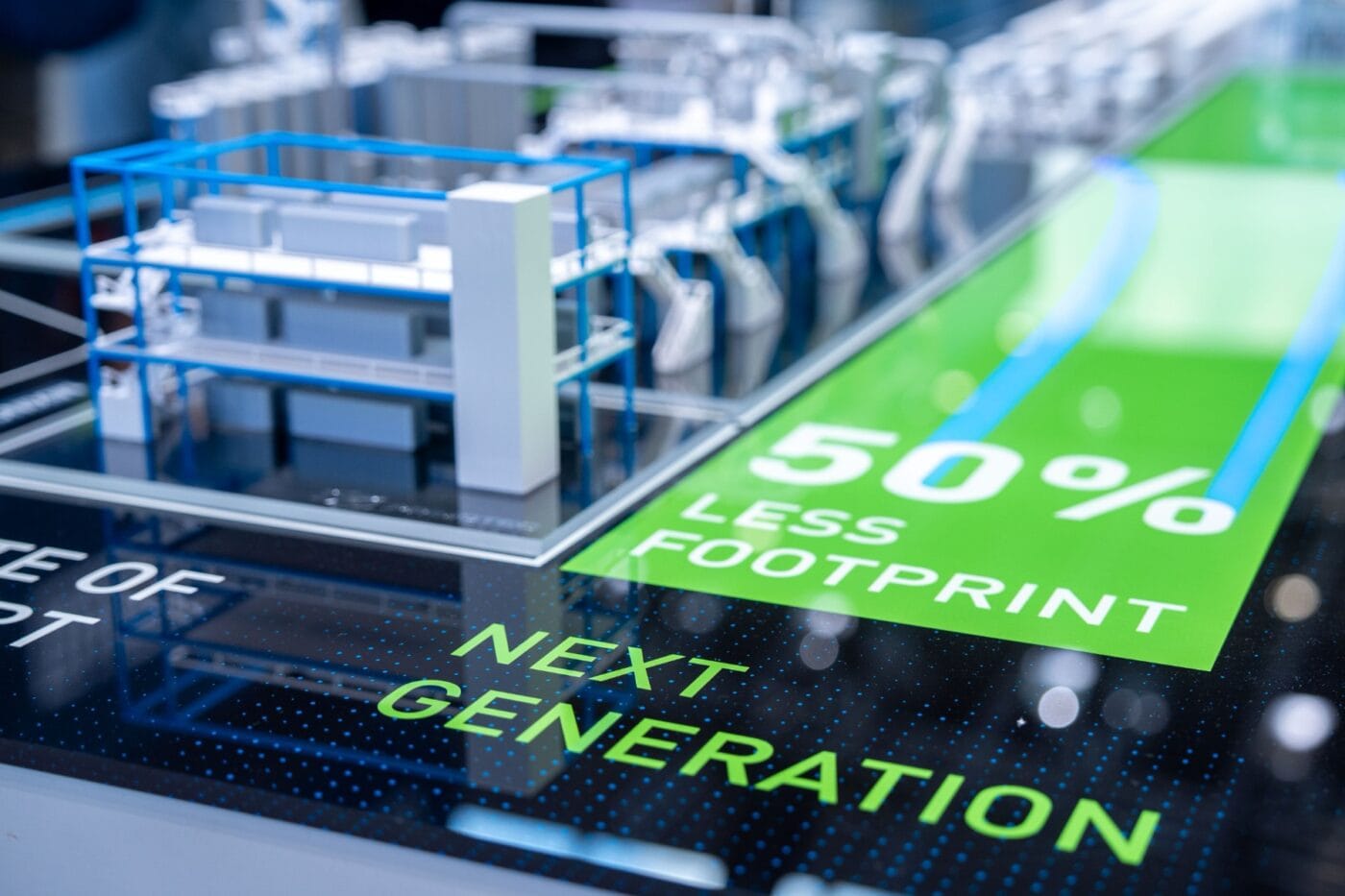

In addition to the conventional wet coating of battery electrodes, the two partners can now also offer production systems with dry coating. “Our concept factory and dry coating in particular represent the next generation of battery cell production,” says Jochen Weyrauch, CEO of Dürr AG. “Thanks to powerful and innovative technologies, production requires 50 percent less space and energy. This means significantly higher space efficiency and lower operating costs for our customers.” German Wankmiller, CEO of the Grob Group, adds: “With our expanded portfolio of high-availability machines and systems, together we cover almost the entire value chain for battery cell production with our own technologies.

By dry coating the electrodes, the large and energy-intensive drying ovens in the battery factory can be dispensed with, for example, and the systems for recovering and processing solvents become superfluous. Instead of the conventional slurry, a dry-mixed active material is used in the “Activated Dry Electrode” process. This powder mixture is pressed into a free-standing film using calendering machines, which is then laminated onto both sides of the collector foil. “The free-standing film also has advantages in terms of material efficiency, as excess film material can be completely returned to the production process before being laminated onto the collector foil. After calendering, the basis weight can be measured directly, allowing better control of the coating thickness. Less force is required for the subsequent lamination onto the collector foil than for calendering in the wet coating process, so there is no deformation of the foil, which improves processability for downstream notching and stacking,” the partners explain in the press release.

Another innovation for Dürr and Grob production systems is the so-called Z-folding, which boasts an integrated notching process. This makes the space requirement of the system smaller. “For a particularly stable and reliable system technology, the separator is guided over a few deflection rollers with a very uniform and low web tension. Thanks to high-quality electrode magazine technology, the system achieves an availability of 95 per cent,” say the companies.

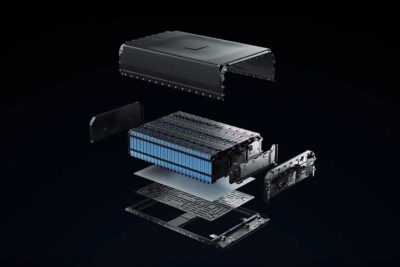

The filling of the almost finished battery cells with an electrolyte has also been improved, with the systems operating at a significantly higher pressure than before, reaching up to 30 bar. This should not only shorten the filling process, but also enable precise dosing. Wet coating processes have been further optimised in terms of performance and energy efficiency, in case customers prefer this technology.

At the Battery Show Europe in Stuttgart (until June 5), Dürr and Grob will be presenting their concept factory as a physical 3D model. Other technologies will also be demonstrated at the joint stand, such as the end-to-end digitalisation of production. This begins in the planning phase with a digital twin and extends to traceability and quality analysis in ongoing production

Source: Info by email, durr.com

0 Comments