ZF aims to simplify drive systems with SELECT platform

With the innovations from the eMobility Tech Day in Zweibrücken, ZF wants to offer a comprehensive product programme for electrified drives in order to meet the requirements of a “dynamic, volatile and technologically differentiated market,” as the supplier announces. This is because the market for e-mobility continues to grow globally. “The large number of drive configurations required is challenging and system providers for e-drives must now have a significantly larger portfolio than just a few years ago. At the same time, customers expect shorter development times, faster innovation cycles, better integration and optimized costs,” wrote ZF.

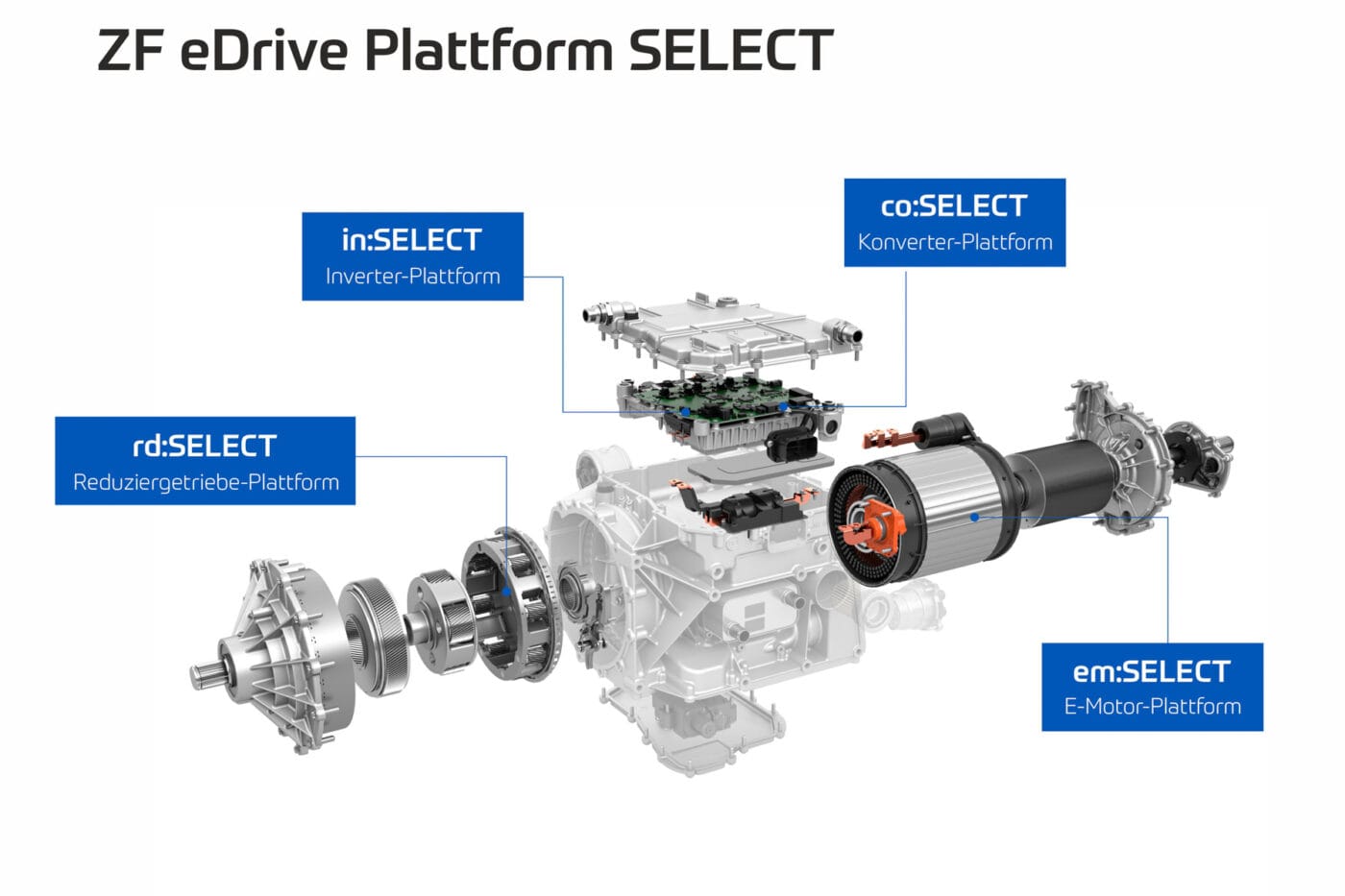

This is precisely where the most important première of the eMobility Tech Day, the SELECT drive platform, comes in. It is designed to enable multi-variant system solutions and includes the necessary components such as electric motors, inverters, converters, reduction gearboxes and software. With modularisation and the ability to flexibly combine these modules according to customer requirements, ZF aims to achieve a broad product range and a high pace of innovation.

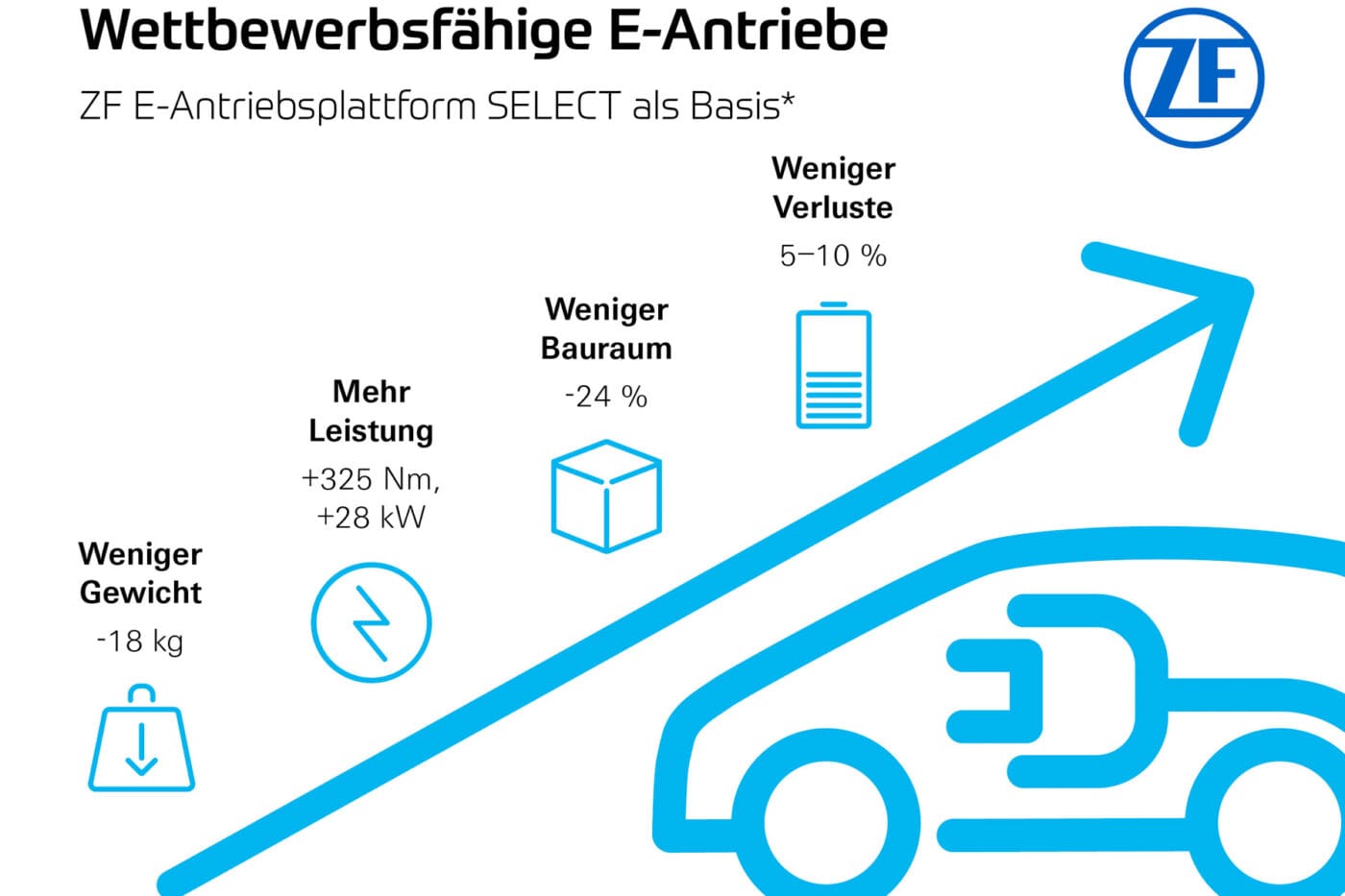

Let’s take a look at the known data on the new drive platform: the SELECT is based on an 800-volt overall system and should be able to cover car drives with an output of between 100 and 300 kW. The supplier states that an electric drive developed on the basis of the SELECT platform beats the current series technology by far in terms of efficiency, power density and other parameters. The new drive offers 325 Nm more torque and 28 kW more power, while weighing 18 kilograms less, taking up 24 per cent less space and reducing losses by five to ten per cent.

Specifically, the platform consists of several component modules, as ZF calls the individual components. ‘em:SELECT’ includes all electric machines from the PSM (permanently excited synchronous machines) and ASM (asynchronous machines) to the I2SM, a separately excited synchronous machine developed by ZF – which is intended to achieve the performance data of a PSM without permanent magnets with rare earths. ‘in:SELECT’ comprises the 800-volt inverters, ‘co:SELECT’ the converters, a key technology for bidirectional charging. The ‘rd:SELECT’ modular system consists of parallel-axis and coaxial reduction gearboxes that are designed for the torques of the electric motors. And ‘sw:SELECT’ is the software library.

For an example of diversity within the component kits, let’s take a look at the ‘em:SELECT’. As mentioned, different concepts such as a PSM, ASM and I2SM are possible. The PSM can also be ordered with a carbon-taped rotor (rotor with carbon bandage) or without. The concept allows the magnetic mass to be reduced, thus lowering the weight and complexity of a conventional PSM rotor without compromising on peak load and top speed. And the stator production system allows electric motors with different outer diameters, active lengths and wire geometries to be quickly assembled into a customised solution. With similar decision paths within the other component kits, a customised drive solution can be created.

ZF also brought a drive developed on the basis of the SELECT to the Tech Day. The primary drive in coaxial design utilises a PSM with 300 kW of power and 5,500 Nm of torque at its core. Compared to the current series technology, the losses at 100 kph should be more than 25 per cent lower, as the supplier calculates. In addition, the drive can maintain a continuous performance of 60 per cent, which is “above the current industry standard.” Additionally, the new drive should also perform better in terms of installation space, weight and costs – although this is not quantified.

ZF states that in addition to innovations at system and component level, attention has also been paid to the industrialisation of the drives. They are geared towards automated production methods and multi-sourcing concepts in order to be able to react appropriately to volatile demand and scale quickly. “No matter where in the world people are driving or what energy sources are available, ZF provides the right solutions to ensure a comfortable and relaxed driving experience,” says Mathias Miedreich, member of the ZF Board of Management and responsible for the Electrified Drive Technologies Division.

Otmar Scharrer, Head of Development at ZF’s Electrified Drive Technologies Division, added: “The pace of innovation in many e-drive components is enormous. Our customers want to have the latest technology available quickly – and with limited integration effort. This is exactly where we come in with our SELECT platform: the overall system and components are perfectly matched to each other – at the same time, the components are interchangeable depending on requirements. We will develop future innovations for series production in such a way that they can be easily integrated into the SELECT platform.”

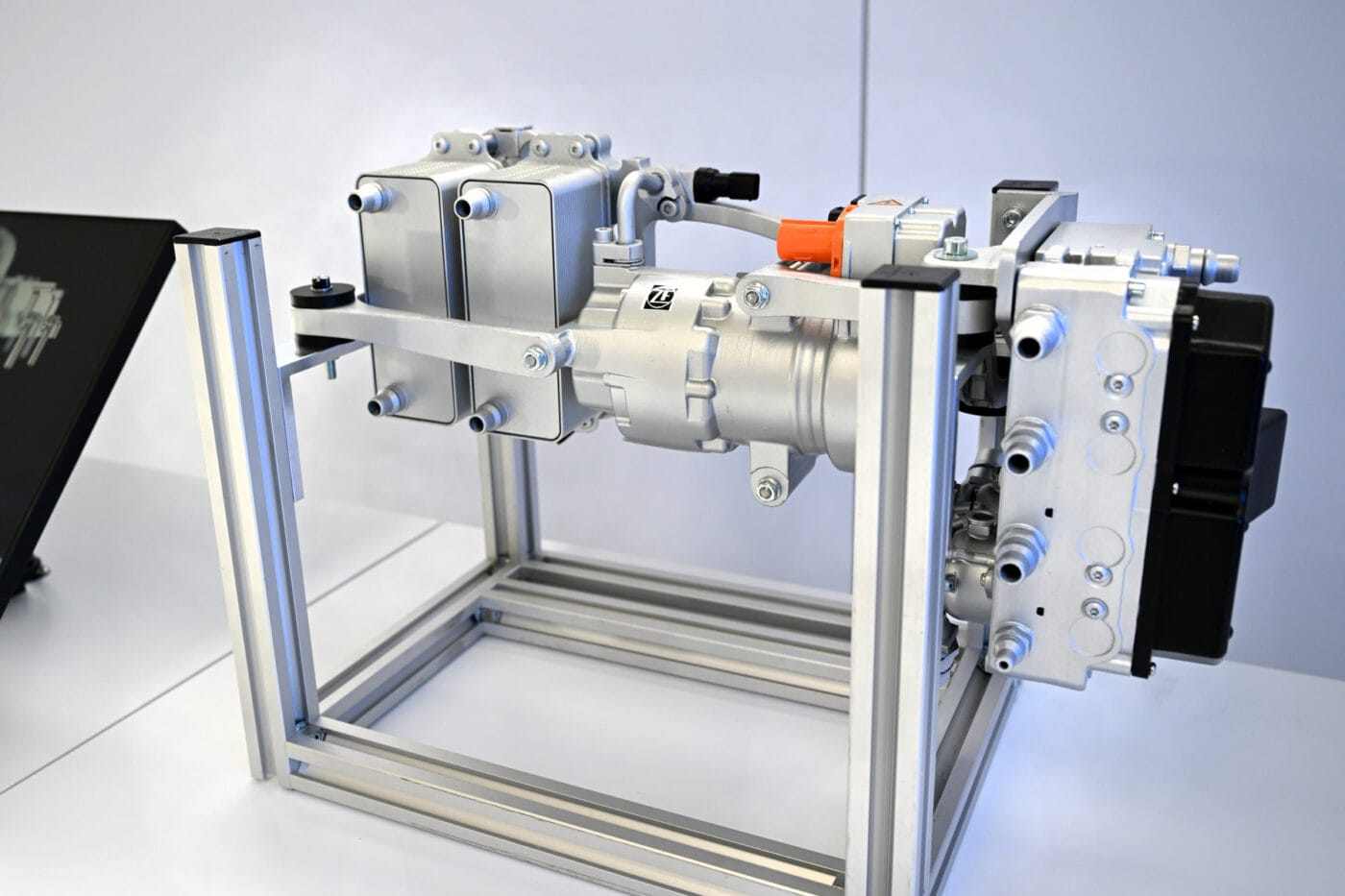

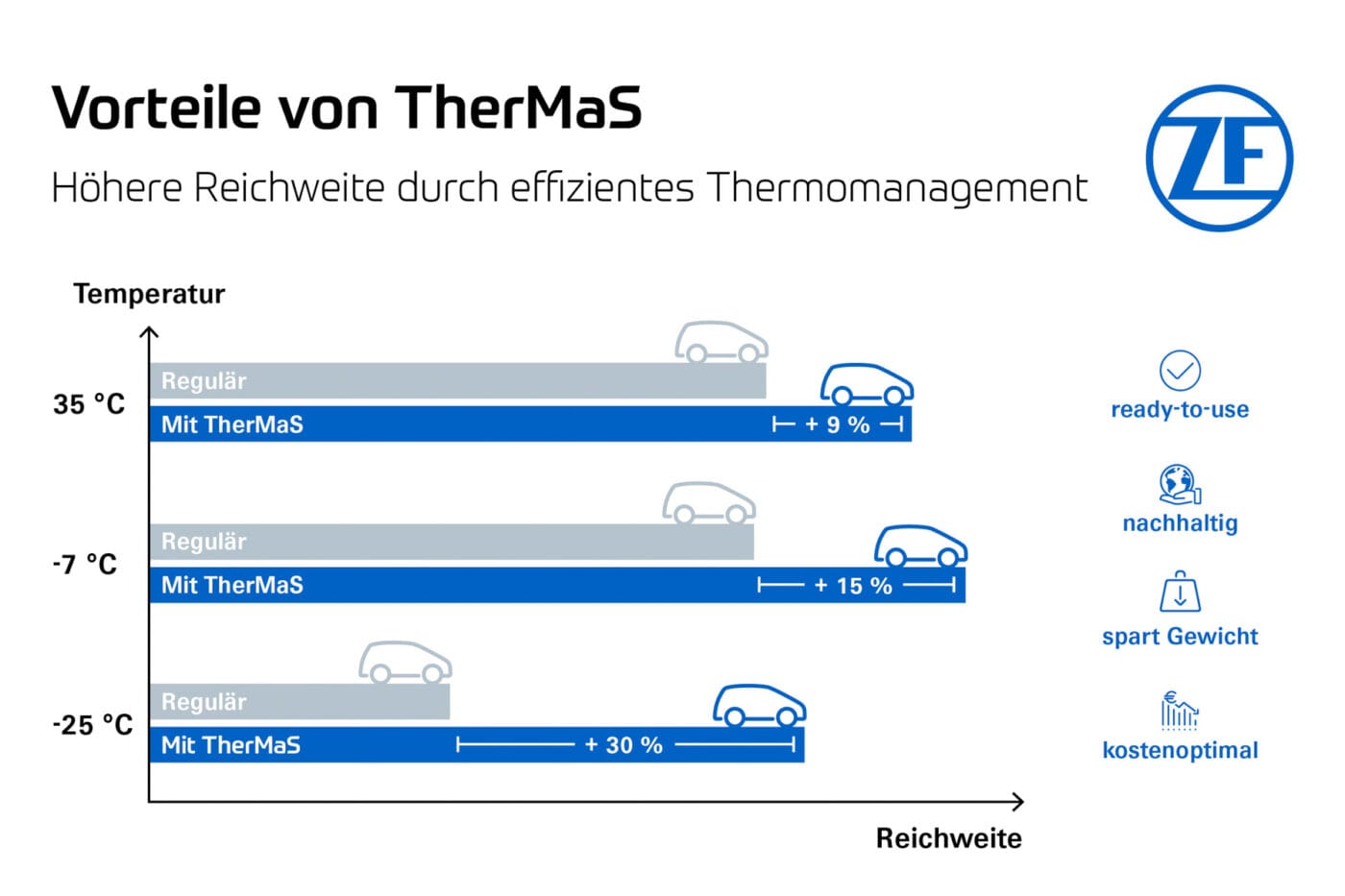

The TherMaS thermal management system, which has been significantly further developed by ZF for electric vehicles, is new and is designed to increase the range of electric vehicles by up to ten per cent through economical air conditioning. Using propane as a refrigerant, TherMaS is designed to deliver cooling and heating capacities of at least 10 kW at outside temperatures of -25°C to +35°C, according to ZF. And as a highly integrated system, the solution should be smaller and lighter than comparable variants – and, as with the drives, also more efficient and less expensive.

“The battery of an electric car, in particular, is very sensitive when it comes to its ideal operating temperature. It feels most comfortable between 15 and 25°C,” explains Scharrer. The ambient temperature therefore, has a major influence on the effective range of an electric vehicle. This is because on extremely cold or extremely hot days, the thermal management system is put under greater strain, which leads to higher power consumption and can almost halve the available range: “Improving thermal management is therefore of great benefit to both the manufacturer and the driver.”

In addition to the all-electric drives, another platform also offers combustion engine and hybrid solutions for all vehicle classes, such as the 8HP evo, which has been further developed with a view to efficiency, performance and flexibility, i.e. the familiar eight-speed automatic transmission for hybrids. “Market requirements have changed drastically in a very short space of time. Hybridisation had already been written off, but now I no longer see the end of the road,” says CEO Miedreich. Markets in Europe, the USA and China have developed very differently and with a variety of electrified drive systems – from full hybrids and plug-in hybrids to battery-electric cars and the booming range extenders in China. “This development is an incredible opportunity for ZF,” said Miedreich.

zf.com (Tech Day), zf.com (SELECT), zf.com (SELECT components), zf.com (TherMAS)

0 Comments