EST-Floattech announces LFP batteries for ships

The Rotterdam-based company develops and produces lithium-ion batteries for electric and hybrid propulsion systems for inland vessels, ferries, and yachts, as well as producing battery management in-house. EST-Floattech says the addition of LFP batteries allows it to address market demand for this cell chemistry. Its Octopus LFP ESS has been engineered for large-scale battery systems and works with the company’s existing Octopus Series Battery Management System (BMS).

“By introducing LFP to our Octopus Series, we empower shipbuilders and operators with even more choice,” says Mark Witjens, CEO of EST-Floattech. “We understand that different vessels have different energy profiles. LFP gives us the ability to serve applications with a high energy capacity demand and long discharge and charge cycles with a robust, safe, and cost-effective solution—without compromising on our commitment to reliability and quality.”

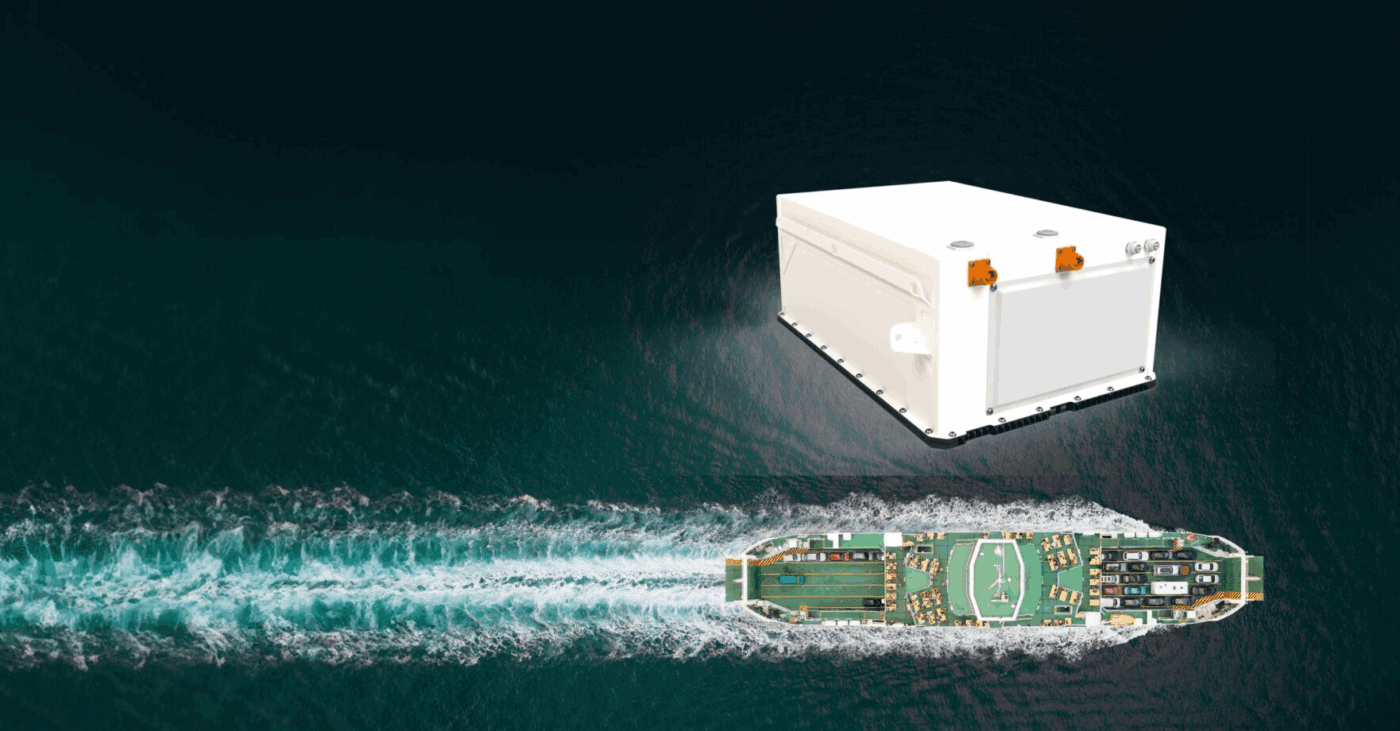

In 2022, the company was involved in converting several inland vessels for which it supplied a 504 kWh battery container. In spring 2024, UK shipbuilder Coastal Workboats announced a battery supply contract with EST-Floattech for a purpose-built Electric-Landing Utility Vessel. The E-LUV is the UK’s first commercial electric workboat and will perform the duties of a Ro-Ro (Roll on Roll off) and dry cargo transportation ferry. The vessel will be equipped with a 2400 kWh Octopus High Energy battery system from EST-Floattech.

LFP batteries, which are generally considered safer and cheaper with sufficient energy density for mobile applications than other battery chemistries, have been increasingly in demand across the automotive sector. The maritime sector is experiencing similar interest in this cell chemistry. “The development of LFP is the logical step for EST-Floattech to cater to the growing demand for different chemistries by shipyards and shipowners,” says Witjens.

0 Comments