DHL and Fortum partner to close EV battery loop in Europe

Under the new agreement, DHL will ensure safe and efficient logistics for Fortum’s operations, including transport, storage and handling of used EV batteries, alongside just-in-time delivery to Fortum’s processing sites. The logistics model is designed to support the technical and safety requirements of battery end-of-life handling, meeting strict regulatory and operational standards.

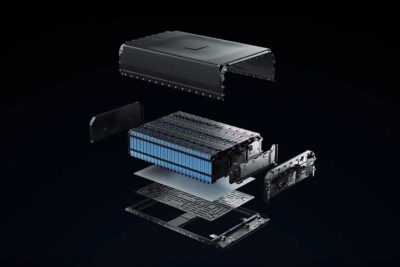

Fortum is currently the only provider in Europe offering end-to-end solutions across the battery recycling value chain. Using hydrometallurgical and mechanical processes, the company recovers critical raw materials such as lithium, cobalt and nickel with high yield and low residual waste—enabling a sustainable, circular approach to battery materials. It recently introduced its new Battery Box service in Germany and Finland. The solution simplifies the collection and recycling of lithium-ion EV batteries, ensuring regulatory compliance and circular material recovery.

For Fortum, the deal is a key step toward scaling its Europe-centric recycling model. “We believe that electrification of Europe is not possible without sustainable recycling of batteries taking place in Europe, for Europe,” said Anssi Airas, Head of Business Line Battery at Fortum. “The cooperation with DHL is an essential building block for our mission to promote the circular economy and maximise resource conservation.”

“Our collaboration with Fortum underscores our commitment to providing innovative logistics solutions to meet the growing demands of e-mobility,” said Hendrik Venter, CEO of DHL Supply Chain EMEA. “Through our expertise in service logistics and our global network, we can help Fortum expand their recycling capabilities while maintaining the highest safety and sustainability standards.”

DHL has been investing a lot in its EV centres and circular economy recently. Just a few months ago, DHL announced that it would expand its EV Centre of Excellence in Rugby in the UK to include a new battery services centre. Developed in collaboration with Cox Automotive, the service centre will deliver a range of services including battery servicing, repair, and recycling. It will be fitted with an £800,000 Battery Energy Storage System which enables EV batteries to be safely discharged and their energy re-circulated into the manufacturing process.

The UK EV Centre of Excellence forms part of a global network operated by DHL, which are located in countries including China, Italy, Indonesia, UAE, Mexico, and the USA. Most of these sites offer warehousing for EV manufacturers, delivery management for parts and vehicles, customs support, and more. With strict regulations concerning safety and storage, DHL says it can ensure compliance as well as logistical support.

0 Comments