Group14 sets benchmark for silicon battery cycle life

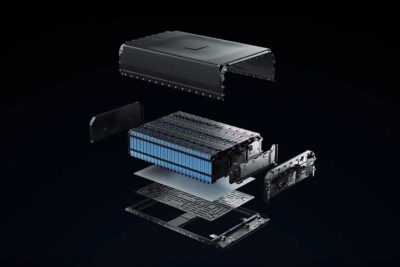

Group14 Technologies has announced a major milestone for silicon battery technology, with its SCC55 material enabling battery manufacturers to achieve more than 1,500 charge cycles – and in some applications exceeding 3,000 cycles. The data was collected from over 20 customers worldwide using SCC55 across electric mobility and energy storage systems.

“The data is clear: silicon batteries have crossed a critical threshold, and 1,500 cycles is the new 1,000,” said Rick Luebbe, CEO and Co-Founder of Group14 Technologies. “This performance benchmark for silicon batteries presents a new era of durability combined with higher energy density and faster charging for all types of rechargeable energy storage.”

For years, the industry benchmark for high-performance lithium-ion batteries has been 1,000 charge cycles. Group14’s silicon-based material now enables battery makers to surpass this target while retaining silicon’s advantages of higher energy density and rapid charging capabilities. This breakthrough addresses the traditional limitation of lower cycle life in silicon-dominant chemistries.

The company emphasised the impact on total cost of ownership for battery-centric sectors such as electric vehicles, electric vertical takeoff and landing aircraft (eVTOLs), and AI data centre energy storage systems. Compatible with chemistries including LFP, LMFP, and high-nickel formats, SCC55 is already powering millions of devices and vehicles globally.

Group14 began shipping the material from its plant in Sangju, South Korea, in September 2024. The Americans operate the manufacturing facility jointly with SK Materials. Test customers used these initial quantities to trial the SCC55 product for use in various battery programmes for electric vehicles and consumer electronics.

The new plant has an initial annual capacity of 2,000 tonnes of SCC55 – enough to power approximately 100,000 to 250,000 electric vehicles per year. To ramp up production and supply chains, electrive recently spoke to Grant Ray, Vice President of Global Market Strategy at Group14, who also spoke in detail about the company’s plans for its SCC55 material.

Group14’s well-known customers include CustomCells and Porsche, although CustomCells had to file for bankruptcy in spring. BASF, a major German corporation, is also among the US company’s partners. In May, the two sides unveiled a market-ready silicon anode solution that combines BASF’s Licity 2698 X F binder with Group14’s SCC55 anode material using a drop-in approach.

0 Comments