LiCAP launches 300 MWh dry electrode line in California

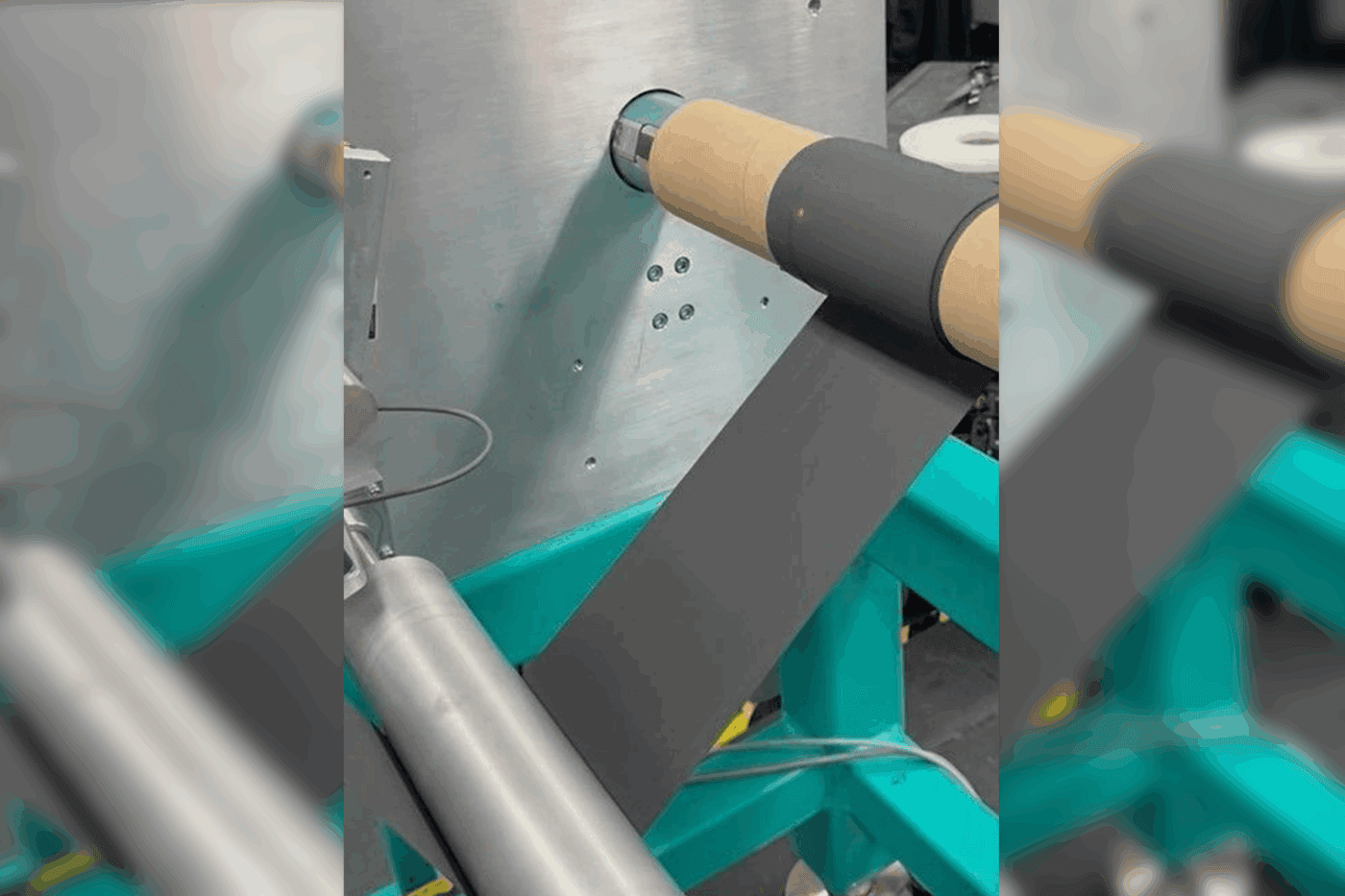

LiCAP Technologies says it successfully produced its first cathode roll exceeding 500 metres in length in July. The production line utilises LiCAP’s proprietary ‘Activated Dry Electrode’ process to manufacture free-standing cathode films without the use of toxic solvents at the company’s facility in Sacramento, California. It eliminates the need for energy-intensive drying steps and solvent recovery systems, offering a more sustainable alternative to conventional slurry-based electrode fabrication.

The coating process was developed together with Dürr and Cellforce. The former have been working together since 2024, while Cellforce joined the partnership in February 2025. The company also joined forces with Siemens and BW Papersystems in 2022 to work on dry electrode manufacturing systems.

The line supports the production of lithium-ion, solid-state, and sodium-ion battery electrodes, and is designed for scale-up to meet industrial volumes. According to LiCAP, the technology offers benefits such as higher energy density, reduced cost per kilowatt-hour, and lower environmental impact—attributes that are increasingly critical as the EV industry pushes for cleaner and more efficient manufacturing.

LiCAP will begin supplying customer samples from the line this month. The company reports growing interest from cell manufacturers seeking alternatives to traditional wet-coating processes, particularly in the EV sector, where dry electrode manufacturing is viewed as a key enabler of next-generation battery production.

The project was funded in part by the California Energy Commission (CEC). “This milestone represents not just technical progress, but a clear demonstration of how public-private collaboration can accelerate the commercialisation of breakthrough clean energy technologies,” said Dr Linda Zhong, Founder and CEO of LiCAP Technologies. “We are deeply grateful for the CEC’s support and shared commitment to building a resilient, US-based battery supply chain.”

“The CEC is proud to support pioneering projects like LiCAP’s LRPL that contribute to California’s clean energy goals while advancing sustainable manufacturing practices,” said Cammy Peterson, Deputy Director of Energy Systems, Innovation, and Strategy at the CEC. “Milestones like this underscore the importance of investing in homegrown technologies that strengthen our economy and reduce greenhouse gas emissions.”

1 Comment