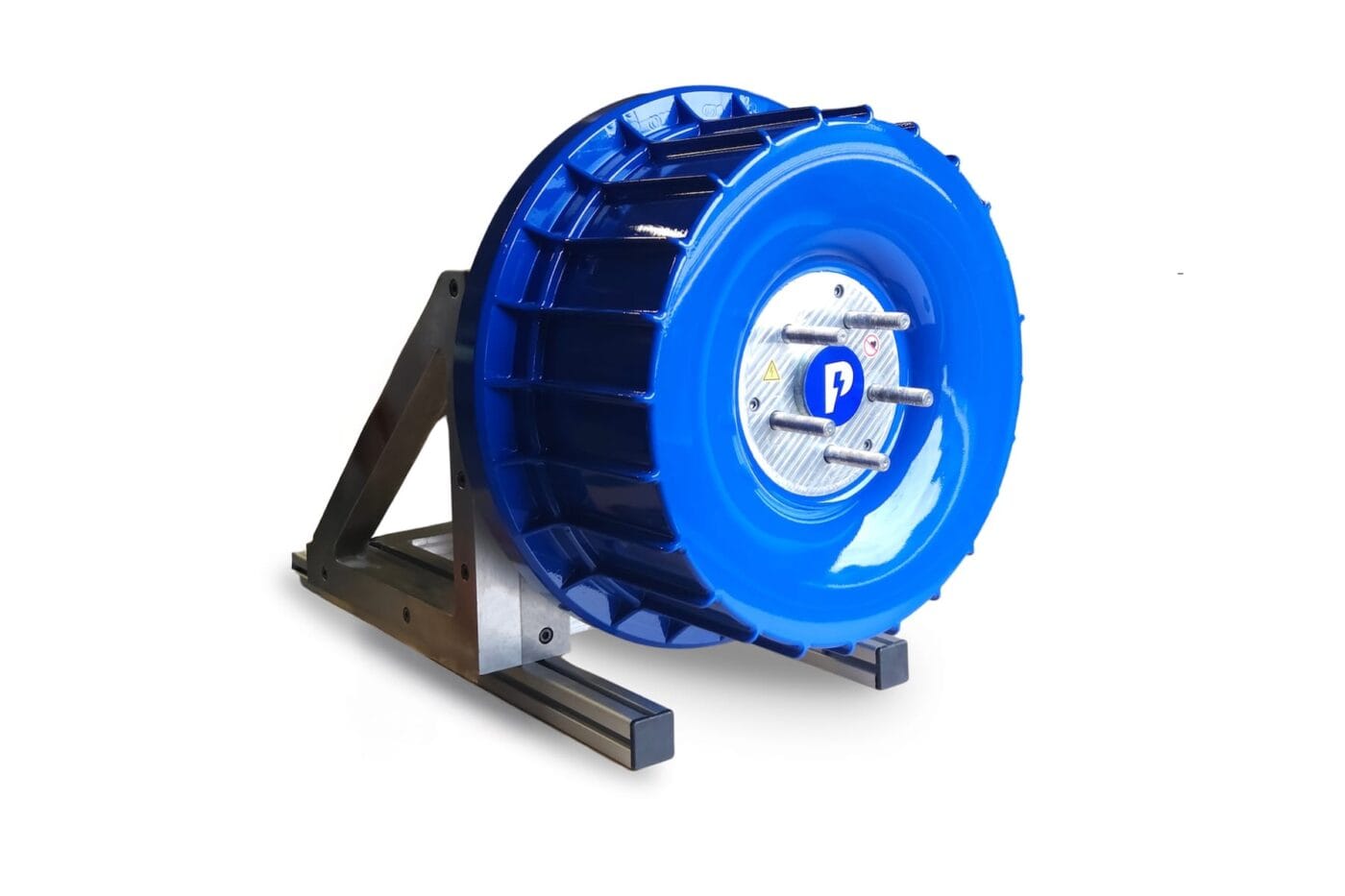

Protean Electric unveils new 220 kW wheel hub motor

Protean plans to start production of this new wheel hub motor next year. It is expected to cost no more than conventional solutions with electric axles, in which the motors are located in the axles and drive the wheels from there.

Wheel hub motors, known as in-wheel motors, have the advantage of not requiring intermediate gears or drive shafts. The motor, brakes and power electronics are housed in a compact unit directly in the wheel. They also make it easier to implement torque vectoring, or the targeted distribution of torque to different wheels. The disadvantages of wheel hub motors include the fact that cooling is difficult to implement and that they add additional unsprung mass to the tyres.

To date, no car manufacturer has yet used wheel hub motors in large-scale production. But Protean Electric now wants to change that. According to the company, a European manufacturer plans to use wheel hub motors in an electric sports car from 2026 onwards. It is not yet clear which manufacturer this is, but the performance data definitely matches that of a sports car. Not only does the motor have an output of 220 kW, but it is also likely to be used on at least two or even four wheels, which naturally increases the system performance significantly. Protean also talks about sporty vehicle acceleration for the sprint from zero to 100 km/h in just under three seconds. This confirms Protean’s position as the first supplier to deliver production-ready, high-performance wheel hub motors for passenger car applications, the company emphasises.

“We have always believed that in-wheel motors make better EVs, and we are able to prove that today. In this industry, better must also mean cheaper, without sacrificing quality or performance,” said Andrew Whitehead, CEO of Protean Electric. “As twin e-axle systems become commonplace, we have shown we can displace them with our ProteanDrive solutions, to deliver cost-effective solutions offering more customer value. We are excited to showcase this at IAA Mobility 2025.”

According to Protean, wheel hub motors are not only comparable in price to electric axles, but also enable cost reductions in vehicle manufacturing, partly because they reduce component complexity and eliminate conventional powertrain elements. This should enable seamless integration of electric vehicle technology into existing platforms with minimal disruption and, in the case of new architectures, greater modularity, higher space efficiency, improved overall efficiency and higher performance metrics.

In-wheel motor technology has been around for some time; for example, the startup Ree Automotive started development of the drive system in 2019. Last year, the company presented a delivery vehicle platform using the technology, with a contract manufacturer announced in September last year. More recently, Elaphe presented its own in-wheel drive platform, which delivers an output of up to 300 kW per wheel. In May of this year, Verge Motorcycles also announced that it had adapted the technology for use in electric motorcycles.

This article was first published by Florian Treiß for electrive’s German edition.

11 Comments