Stellantis launches practical tests with IBIS prototype vehicle

The French IBIS project was launched six years ago and combines academic research with industry expertise. Back in 2023, the 25-strong team presented its first prototype of a battery with integrated inverter and charging functions. At that time, only a stationary demonstration model was shown with the aim of incorporating it into a car as soon as possible.

Now the time has finally come: for the first time, the innovative battery system has been integrated into a Peugeot E-3008, based on the STLA Medium platform. According to the project partners, the prototype is the result of years of development work, modelling and simulation by Stellantis and Saft with the support of E2-CAD, Sherpa Engineering and French research institutions such as the CNRS, the Université Paris-Saclay and the Institut Lafayette.

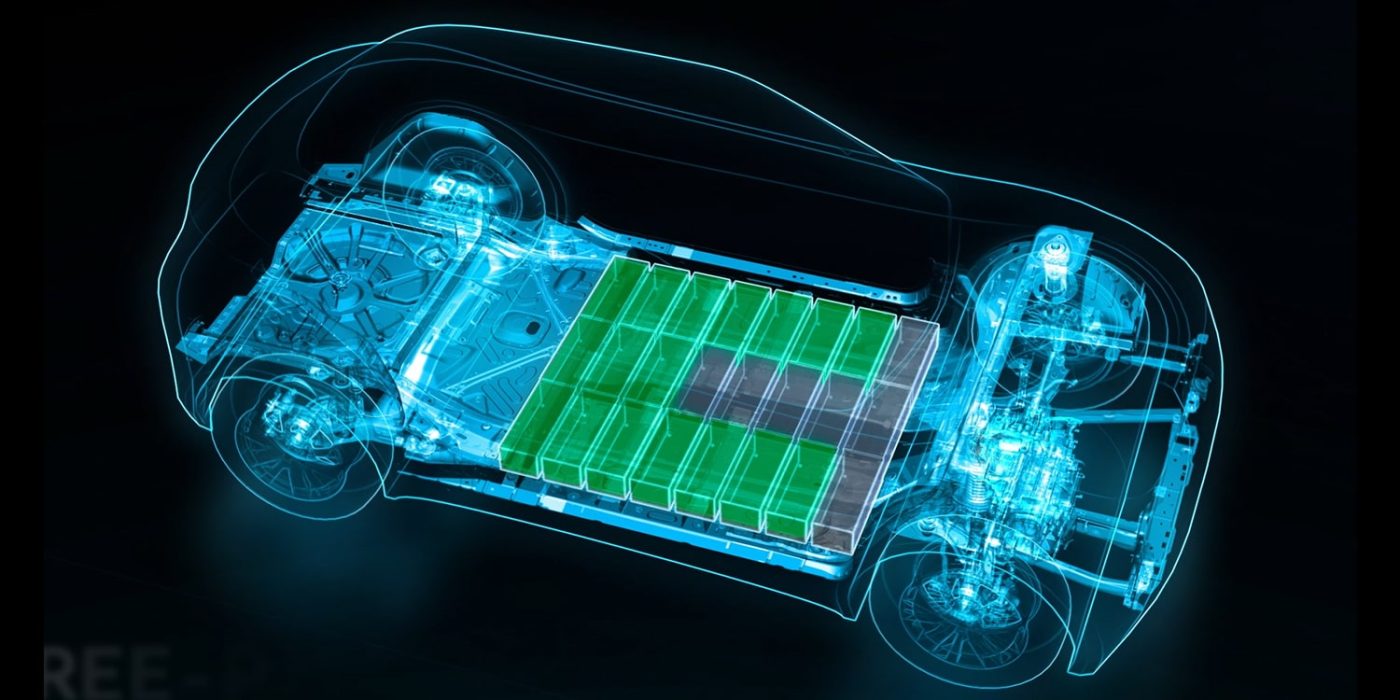

As mentioned, what makes the system special is that the inverter and charging functions are directly integrated into the battery. The architecture supports both alternating current (AC) and direct current (DC) and supplies electrical energy directly to the motor or the vehicle’s electrical system, while simultaneously powering the 12-volt system and auxiliary units. Stellantis cites the following advantages of the system:

- Efficiency & performance: Up to 10% improvement in energy efficiency (WLTC cycle) and 15% increase in power (172 kW vs. 150 kW) with the same battery size.

- Weight & space savings: Reduces vehicle weight by ~40 kg and frees up to 17 litres of volume, enabling better aerodynamics and design flexibility.

- Faster charging: Early results show a 15% reduction in charging time (e.g. from 7 to 6 hours with a 7 kW AC charger) and 10% energy savings.

- Simplified maintenance: Easier maintenance and better conditions for reusing second-life batteries in both automotive and stationary applications.

Ned Curic, Chief Engineering and Technology Officer at Stellantis, said: “This project reflects our belief that simplification is innovation. By rethinking and simplifying the electric powertrain architecture, we are making it lighter, more efficient, and more cost-effective. These are the kinds of innovations that help us deliver better, more affordable EVs to our customers.”

Hervé Amossé, EVP Energy Storage Systems at Saft, added: “The IBIS project is a powerful testament to Saft’s innovation leadership. By embedding IBIS technology into our next-generation applications, we’re unlocking a new era of intelligent, flexible, and sustainable energy solutions. Saft continues to lead the way in advanced research, offering long-term, cost-effective solutions tailored to evolving market needs.”

The IBIS project is now focusing on practical tests under realistic driving conditions, which could pave the way for the integration of IBIS technology into Stellantis production vehicles “by the end of the decade,” according to Stellantis. This is a more cautious statement than the one made in the 2023 press release. At the time, Stellantis stated: “The plan is to bring this technology to market in vehicles from the Stellantis Group brands before the end of this decade.”

Incidentally, the IBIS project is not the only one working on integrating inverters and charging functions into the battery. In March, for example, Porsche Engineering unveiled an AC battery system that integrates the normally separate functions of the battery management system, pulse inverter and on-board charger into a single component.

This article was first published by Florian Treiß for electrive’s German edition.

0 Comments