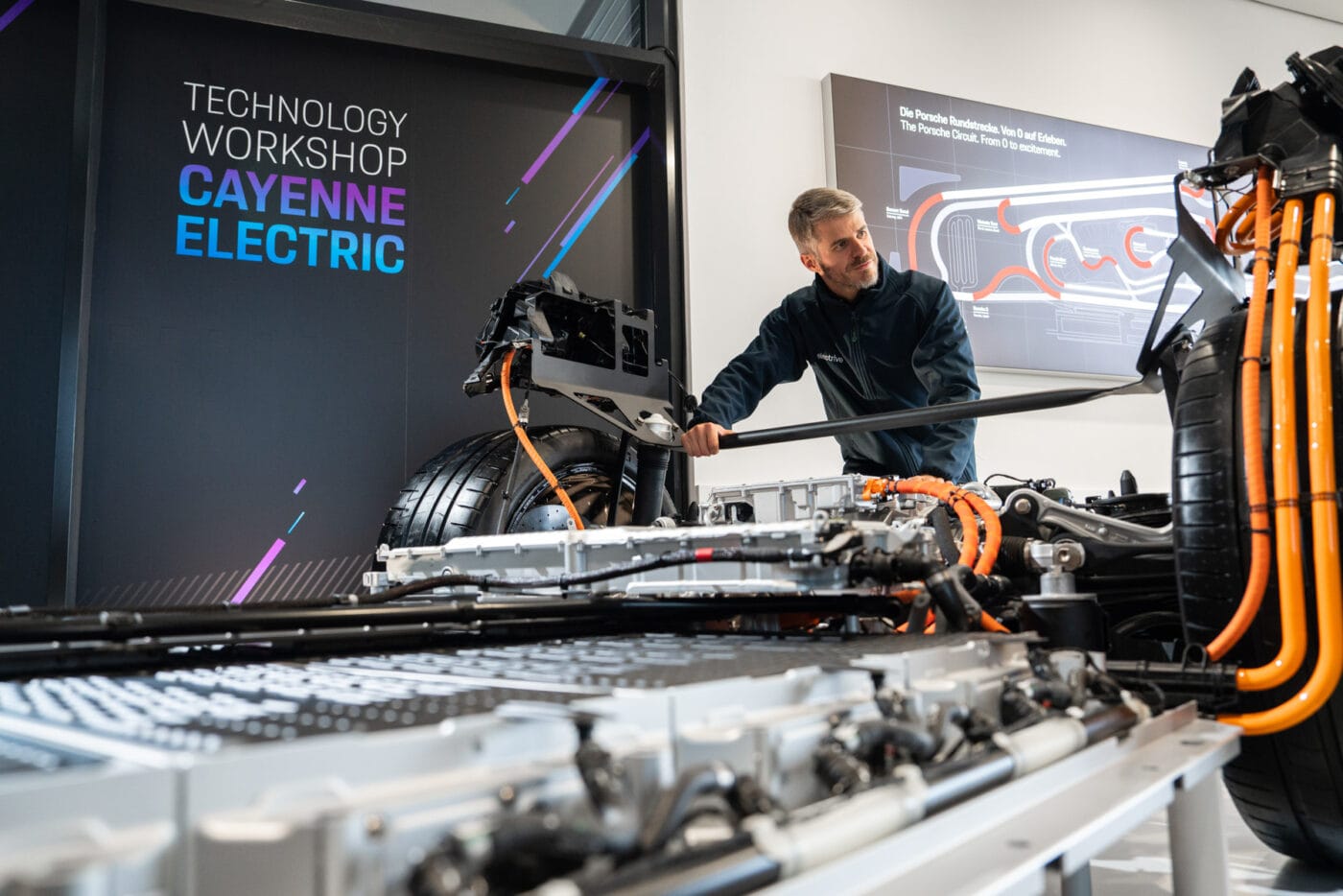

Deep Dive: How Porsche further developed PPE for the Cayenne

Porsche invited electrive to a technology workshop for the new Cayenne at its Experience Center at the Leipzig plant. For the legacy performance carmaker, new technology for its electric cars comes at a critical time: just a few days ago, the company not only revised its profit forecast downward for the current year but also announced a new product strategy. The company has abandoned its once ambitious goal of achieving an 80 per cent electric share by 2030. In the new strategy, combustion engine models are going to be taking up more space again and offered “well into the coming decade” – including with completely new successor generations. At the same time, the development of another electric platform has been put on hold to be “rescheduled.” The iconic German carmaker from Zuffenhausen considers itself to be well-positioned with the electric models currently available and those currently in development.

In light of this strategy, Porsche is now putting the spotlight on its next electric model: The fourth generation of the Cayenne was originally supposed to lead the SUV model into the electric future, flanked for a few more years by the third-generation Cayenne as a combustion engine and plug-in hybrid, before only the purely electric model would be offered. This plan is now obsolete, and the combustion engine and hybrid Cayenne, known as the E3, will continue to be available and will probably also have a successor parallel to the E4, as the electric Cayenne is known internally. For customers, there will therefore be two Cayenne models with the same name and in the same segment but based on different technical platforms.

The electric Cayenne is “not just a product update, but a new chapter in the model’s more than 20-year history,” says Matthias Lederer, Vice President Development Verification and Validation, responsible for all testing systems. In fact, the Cayenne, which has been on the market since 2002, has opened new doors and markets for Porsche. The 1,500,000th model recently rolled off the production line in Bratislava, where the SUV model has been manufactured since 2017. “The Cayenne has always been our platform for innovation,” says Lederer, pointing to features such as PASM (Porsche Active Suspension Management) chassis control, PTC (Porsche Traction Control) drive control, and Matrix LED headlights, which were first offered internally at Porsche in the Cayenne before finding their way into other models.

Lederer has set a high bar for the upcoming electric model: “The Cayenne Electric will define what performance means in the future!” So, let’s take a close look at the technology behind this statement.

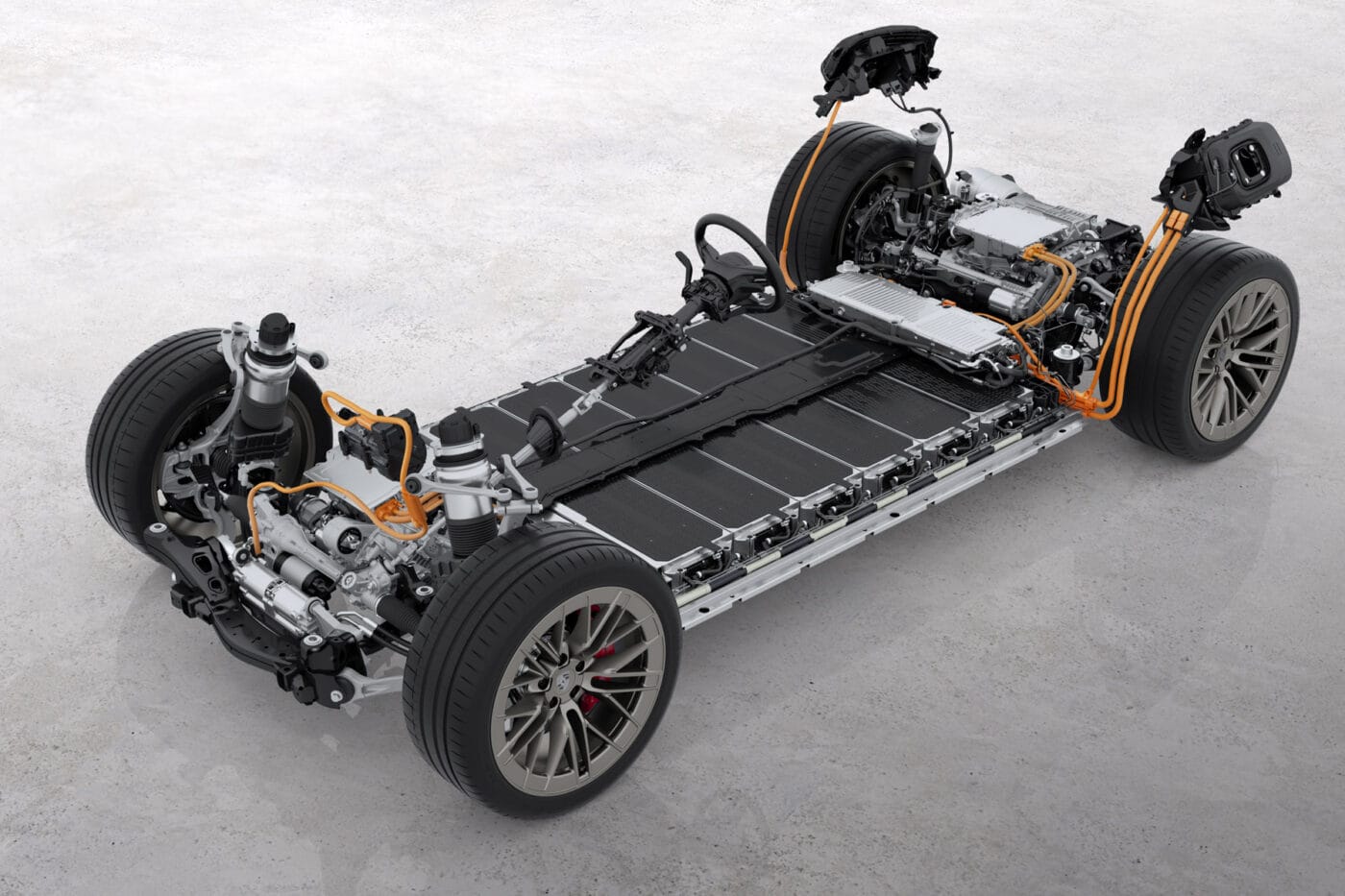

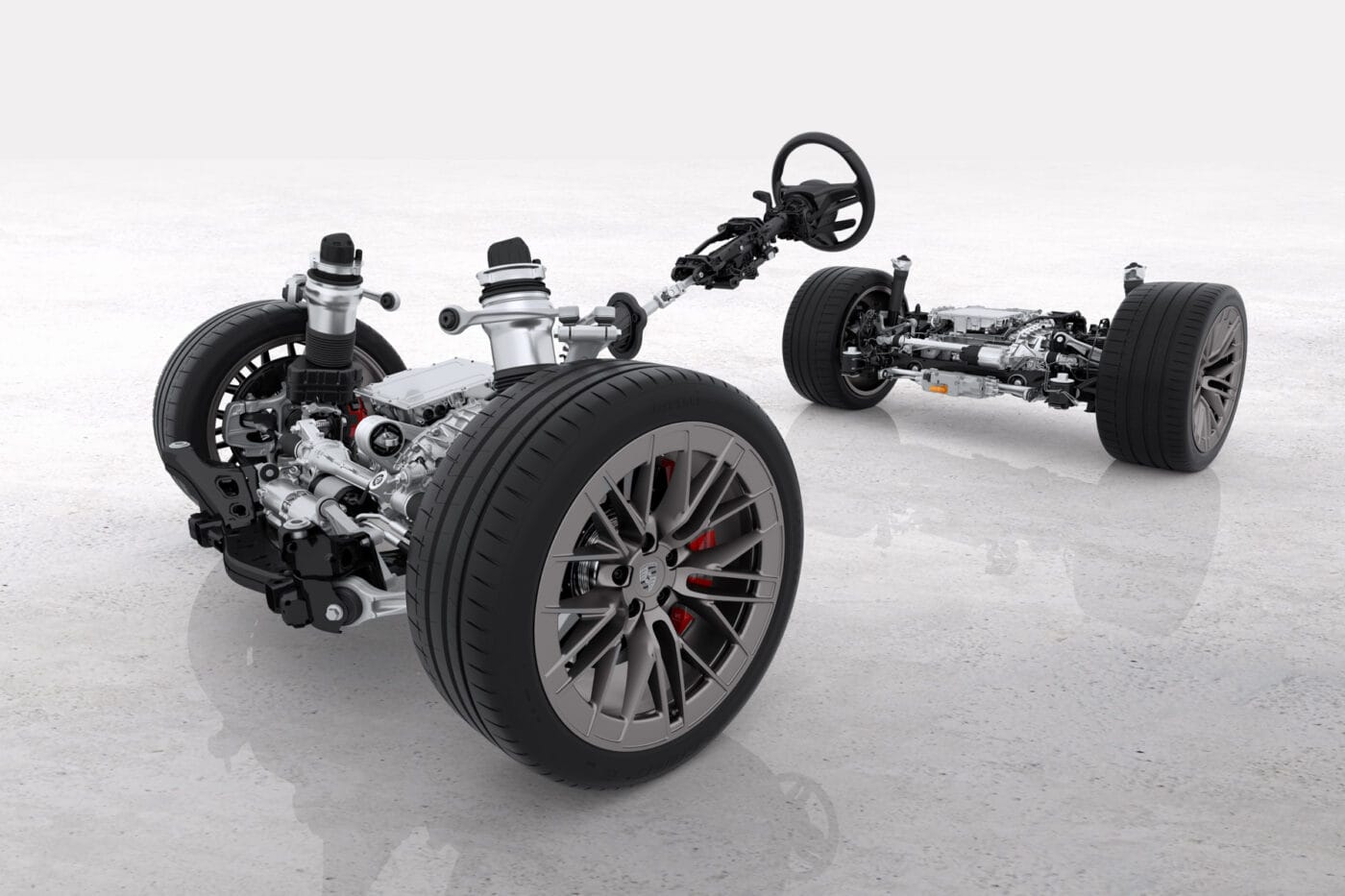

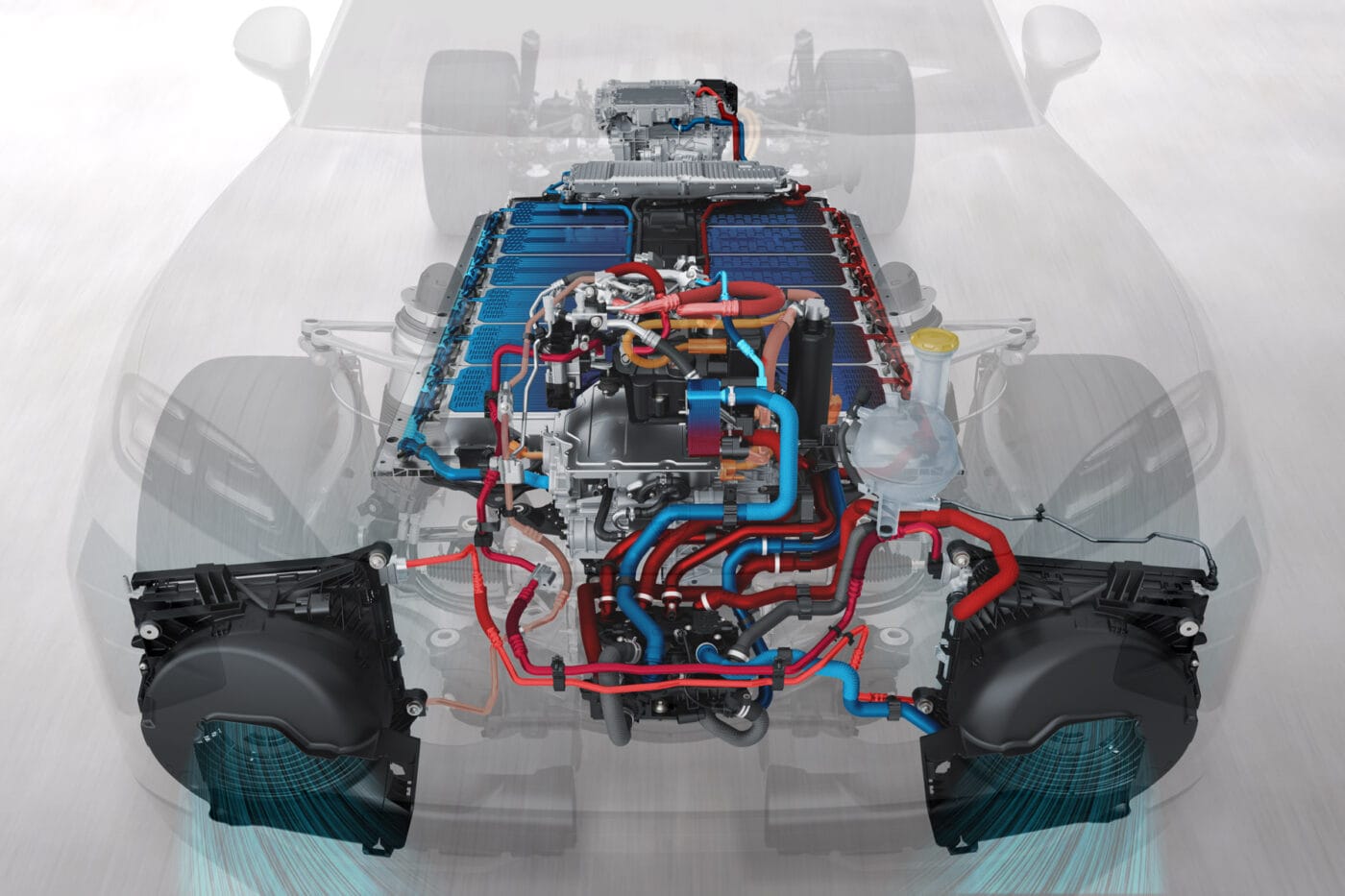

The drive system

In the SUV segment, the key figures are certainly impressive: with over 800 kW of power in Launch Control with ‘overboost’ function, the Cayenne can accelerate from 0 to 100 kph in under three seconds thanks to more than 1,500 Nm of torque. This means Porsche has broken the 1,000 hp barrier in a freely available production model. Even without Launch Control, it still delivers more than 600 kW of power, with an additional 100 kW available for ten seconds via the push-to-pass button on the steering wheel, bringing the total to 700 kW. The figures quoted are for the top model in the series, which, like the Macan, is likely to be introduced as the Cayenne Turbo.

One might expect, since Porsche has developed completely new electric motors for the first PPE model, the Macan unveiled in early 2024, that the Cayenne, scheduled to make its world debut later this year, would adopt these very same electric motors. With perhaps a little more power in the larger model.

But you would only be partially right: the electric motor on the front axle does indeed come from the Macan. This is a permanently excited synchronous motor (PSM) with a diameter of 210 millimetres and an ‘active length’ of 100 millimetres – the housing itself is longer than those ten centimetres. You can read all the details about the Macan powertrains in our first deep dive into PPE technology.

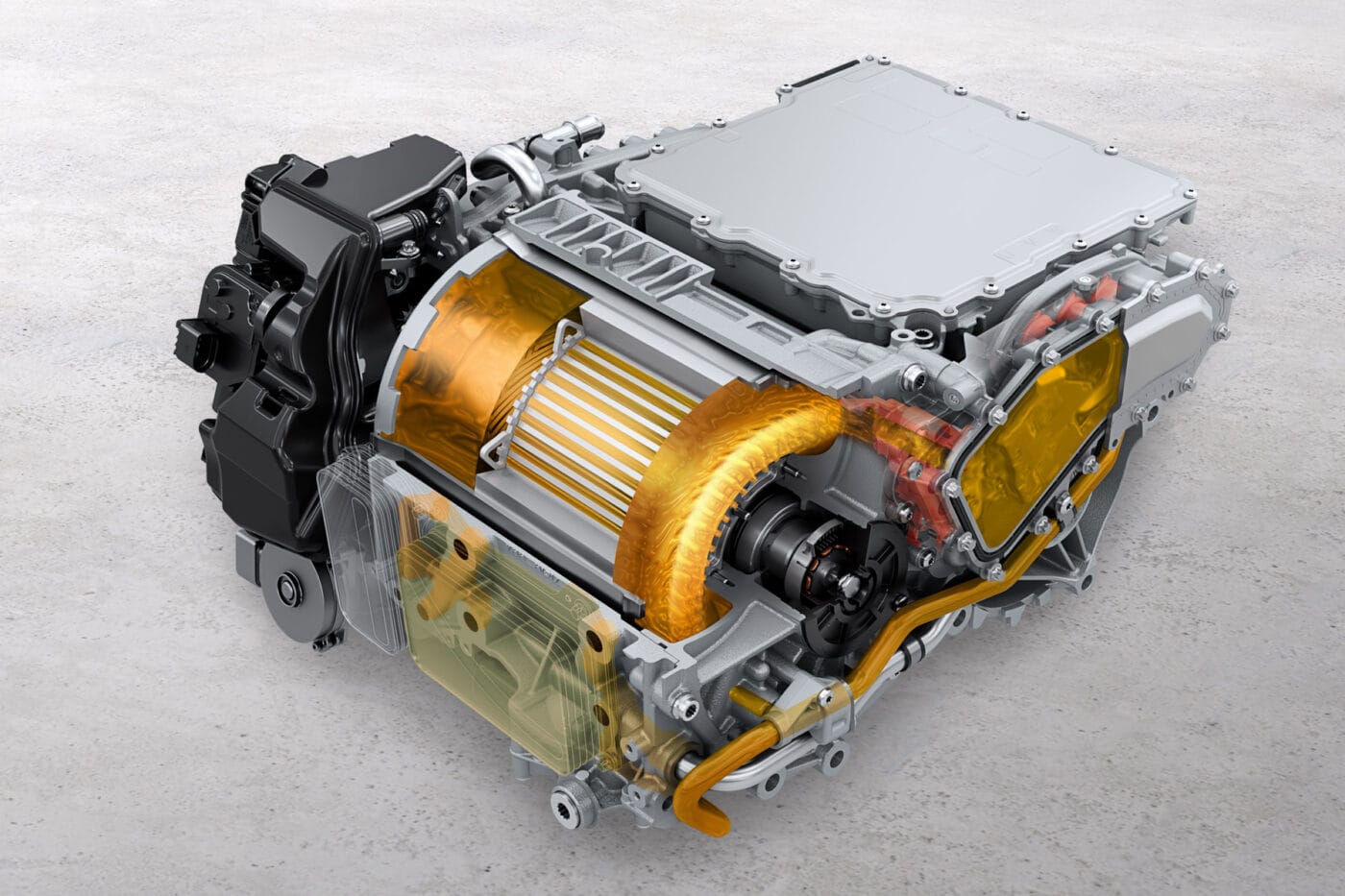

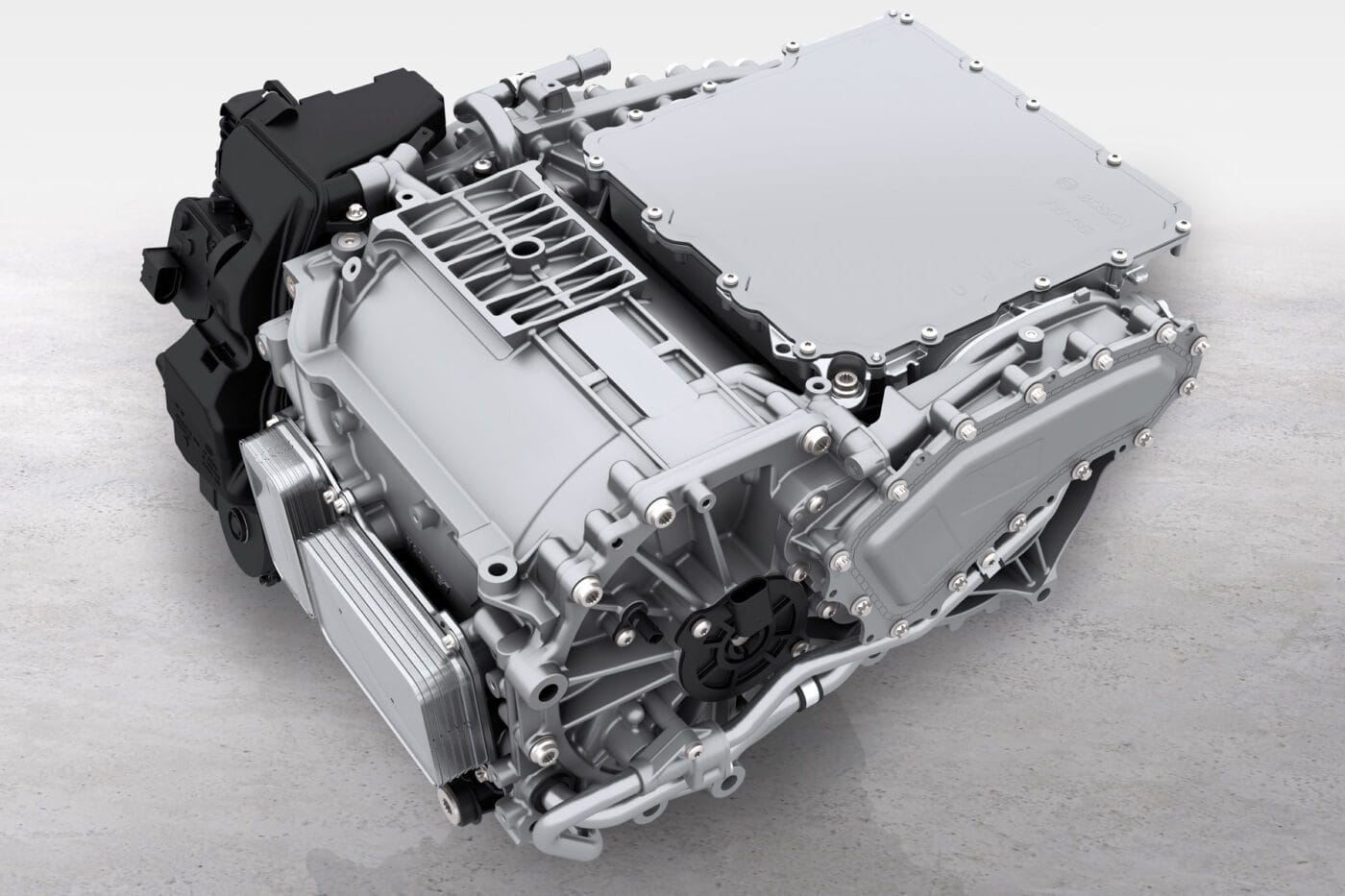

Porsche engineers at the Weissach Development Centre have designed a completely new motor for the rear axle of the Cayenne. It is still a PSM, which uses permanent magnets in the rotor and therefore requires rare earths. Unlike its sister brand Audi, where asynchronous motors without permanent magnets are used in some of its PPE models, Porsche places a special focus on performance in line with its own brand standards. And when it comes to power density, PSM units are still at the forefront.

What sets the new Cayenne drive system apart from the Macan rear-axle drives is not only its dimensions (245 millimetres active length compared to 210 or 230 millimetres, depending on the Macan model variant), but also another performance feature: cooling. Electric motors are usually cooled with what is known as water jacket cooling, where the water jacket flows past the outside of the stator – a simple and inexpensive solution. In the Cayenne, however, Porsche relies on direct oil cooling.

The cooling oil flows through a thin gap between the stator and rotor. “This allows the heat to be dissipated directly where it’s generated,” explains the Porsche electric drive developer Vivien Schreiber. “This is much more efficient and accurate. It allows us to immediately dissipate the heat generated at high currents before it heats up other parts of the motor and we have to reduce power due to the temperatures.”

The result hasn’t yet been revealed precisely in figures, since Porsche will only announce the exact performance figures at the world premiere of the Cayenne. As Schreiber makes clear, the Cayenne’s continuous power output should be very close to the previously communicated peak power of 600 kW. Until now, the difference between continuous and peak power has been significantly greater, precisely because even with the highly efficient water jacket cooling, power had to be reduced after a relatively short peak in order to keep temperatures within limits. This is not the case with direct oil cooling.

Porsche has developed a new tandem oil pump for the system that uses a single drive to supply two different circuits with the appropriate oil pressure – one for lubricating the single-speed transmission and one for the new cooling circuit. The cooling oil itself is a special development in collaboration with ExxonMobil. “The cooling oil is about five times thinner than engine oil,” explains Schreiber. A conventional oil would not have flowed as well through the narrow gap between the stator and rotor and would have caused higher resistance. The heated oil then flows through a heat exchanger located at the front of the motor, which is connected to the vehicle’s thermal management system, located under the bonnet near the front electric motor, but more on thermal management shortly when we get into the nitty-gritty of the battery.

At the Porsche technology workshop in Leipzig, where electrive was able to glean technical insights, the carmaker only presented its upcoming top model, the Cayenne Turbo. We can assume that there will, of course, be other drive variants upcoming. These will include, but not be limited to, the use of the new drive system with direct oil cooling. Reading between the lines, it seems that there will also be Cayenne variants that will feature the rear drive units from the Macan. Possible options include the 285-kW drive from the Macan 4, the 330-kW variant from the Macan 4S (both with an active length of 210 millimetres) or the 430 kW drive from the Macan Turbo with an active length of 230 millimetres on the rear axle.

One thing the Cayenne E4 will not have is pure rear-wheel drive. The entire series is designed as all-wheel drive. Both the Macan and the Taycan have a basic version with only one drive.

With up to 800 kW of drive power, the Cayenne can naturally also achieve strong deceleration values by means of the electric motors. Porsche specifies a recuperation power of up to 600 kW for the top model, which is on a par with the Formula E racing car 99X Electric – and highly unusual in road cars. Incidentally, this is not a theoretical value; Porsche itself measured over 600 kW during test drives. In everyday use for most customers, the recuperation power will be significantly lower: “To reach 600 kW, you need to have sufficient kinetic energy,” explains drive expert Schreiber. What she means is that you have to be travelling at a minimum speed of 230 kph and then decelerate to a standstill using only electric power. In fact, even more power would be possible, but Porsche has set a limit here: the more powerful electric motor on the rear axle would still have reserves for recuperation. This was decided against because it would shift the brake balance too far to the rear, which would lead to unstable handling.

When it comes to recuperation itself, Porsche remains true to its concept. There isn’t a one-pedal drive, and customers can choose between three modes for coasting recuperation by means of the vehicle settings: the standard setting, which corresponds roughly to the engine brake of a combustion engine, coasting with recuperation deactivated, and an automatic mode in which the vehicle calculates the optimum recuperation on its own. Like the other electric Porsche models before it, the Cayenne’s deceleration mechanisms are primarily electric when the driver presses the brake pedal. It’s only when deceleration is most pronounced that the system selectively engages the disc brakes on each wheel to increase deceleration.

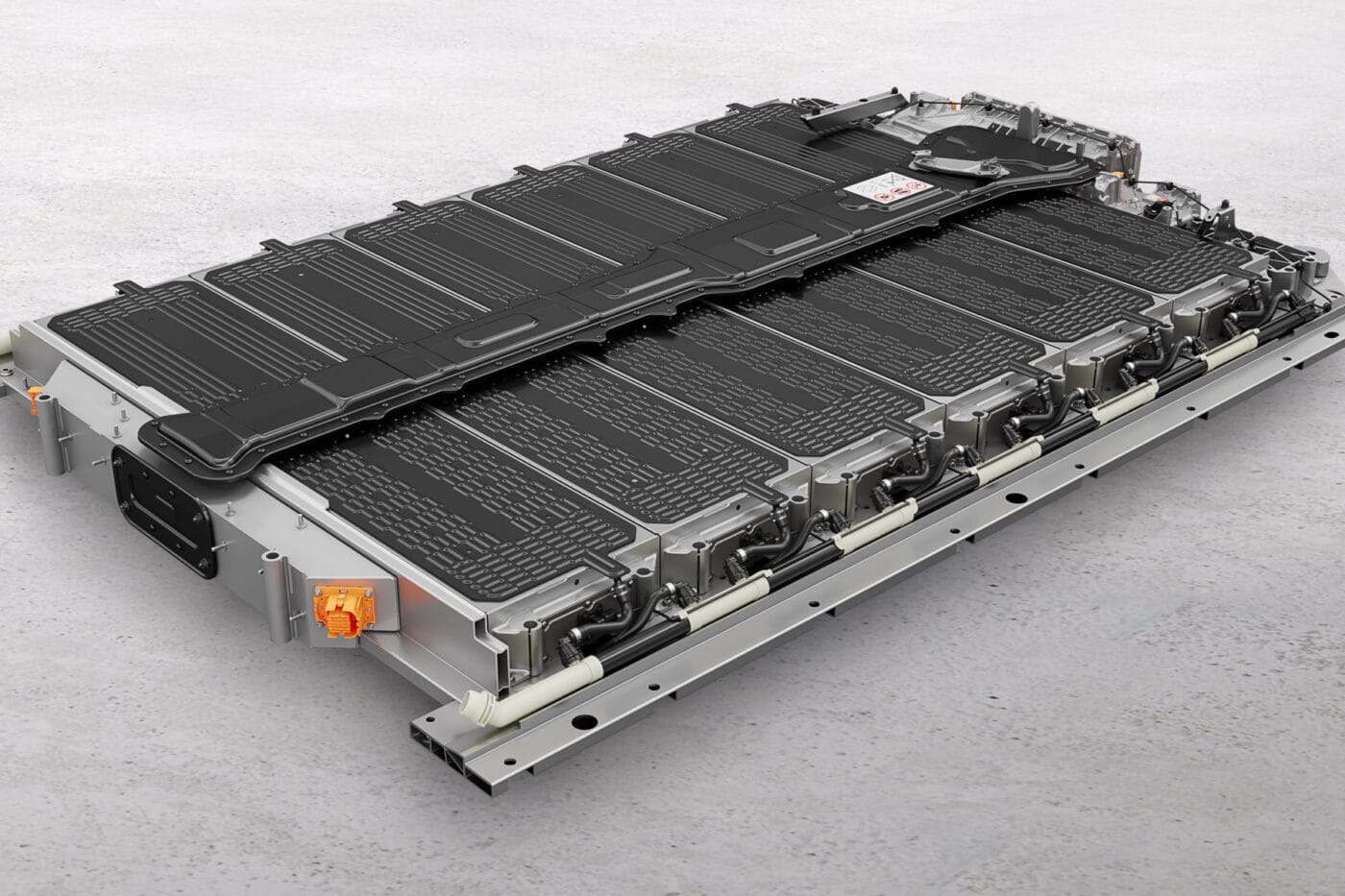

The battery

A number of details about the battery were leaked during the technology workshop in Leipzig. When a few journalists were allowed to ride along in the passenger seat during test drives, it became clear that 113 kWh are installed in the underbody, of which 108 kWh are usable net. Compared to the 95 kWh in the Macan, it seems obvious that the larger Cayenne simply has a larger Macan battery with additional modules in the battery pack. But this is not the case here either; the battery in the Cayenne is completely new.

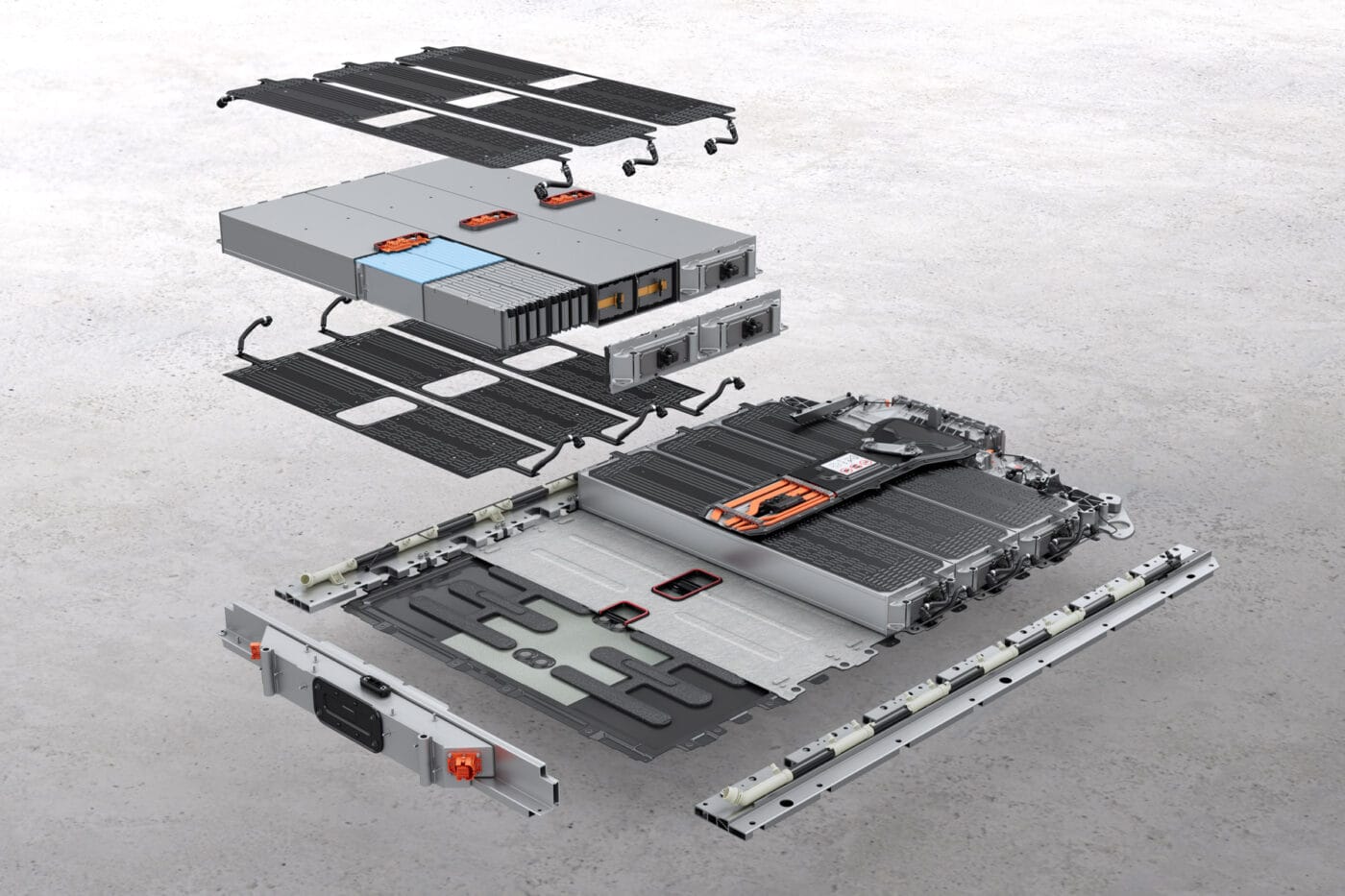

Almost everything about this battery system is new. Neither the cells, nor the modules, nor the pack have been passed on from the Macan to the Cayenne, and the massive battery pack no longer exists in this form in the Cayenne. In the Cayenne, six large modules are integrated into a kind of subframe, equipped with underride protection and then mounted under the vehicle. There is no longer a comprehensive and dense battery pack integrated into the body as a load-bearing component. Porsche refers to this as a ‘module to car’ approach. There is still one thing the batteries of the two models still have in common: the Integrated Power Box (IPB) is located at the rear end of the battery, i.e. under the rear seat bench. The IPB developed for the PPE combines three components: the onboard AC charger that converts alternating current (AC) to direct current (DC) during charging; the high-voltage heater to control the temperature of the HV battery and interior; and the DC/DC converter, which supplies the 12-volt electrical system.

The six large modules run across the entire width of the battery and are arranged one behind the other. Since there is no longer a battery pack as such, it is not possible to place a cooling plate at the bottom of the pack that the modules sit on, as is usually the case. Instead, each Cayenne battery module has two cooling plates, one at the top and one at the bottom – but more on the cooling concept in a moment.

The idea is that if a defect or other damage occurs, the battery subframe can be separated from the vehicle, and only the affected module can be easily replaced. This would also be possible if the modules were installed in a pack, but it would be much more complicated: the cover of battery packs is sealed and either screwed or glued in place, depending on the model. Everything would have to be hermetically sealed again in order to replace a module or simply check the cabling. In the six Cayenne modules, the control units are also located on the outside of each module on the driver’s side. If only the control unit is defective, the circuit boards can be replaced without having to remove the module from the frame.

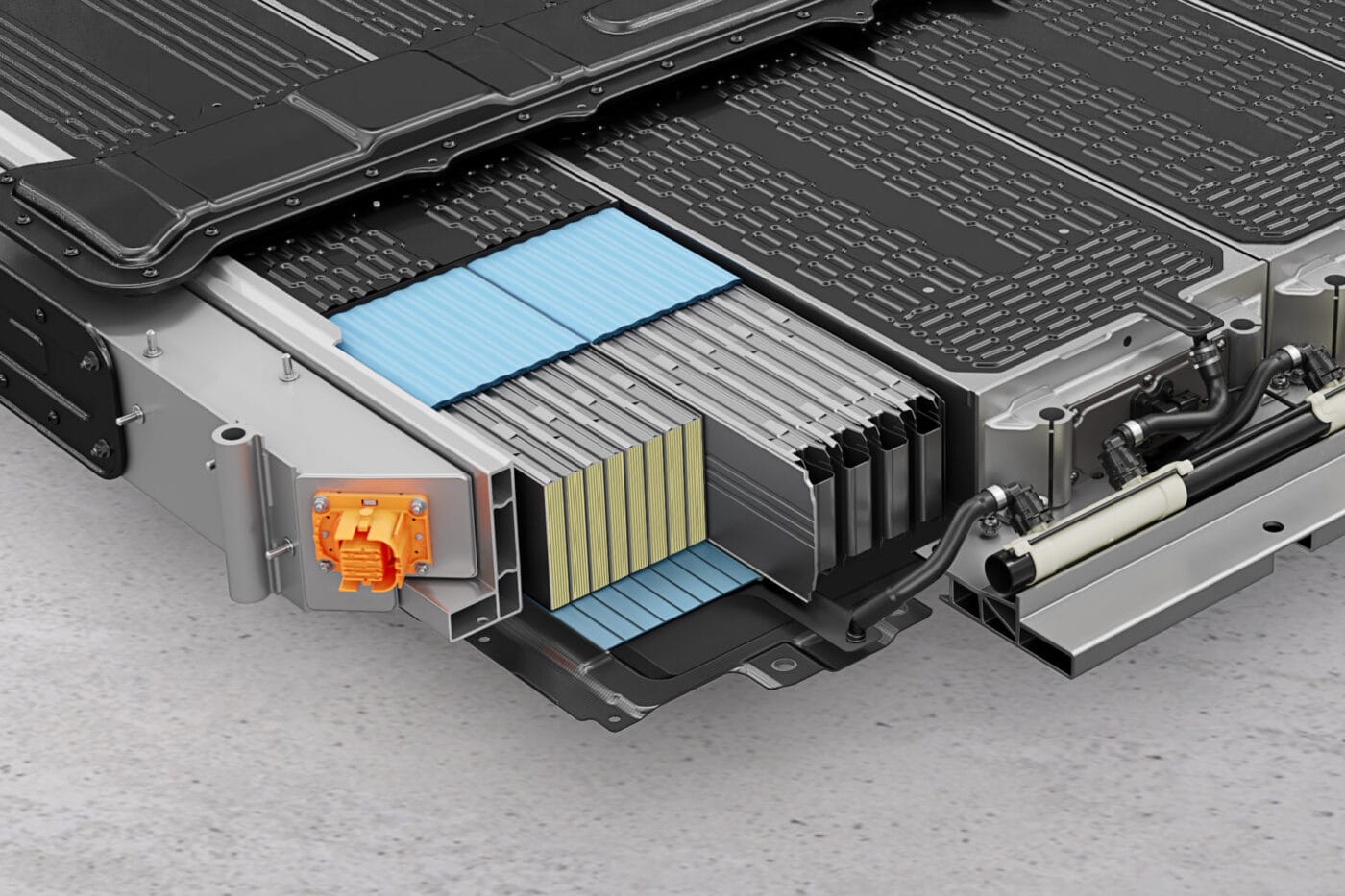

The new modules are also harbouring a new feature: while the Taycan and Macan use prismatic cells (VW Group’s ‘standard cell’ is also prismatic), the Cayenne uses pouch cells. There are 32 of these cells per module. Each module contains four cell stacks of eight cells. All cells are connected in series, resulting in what is called a 192s1p1 configuration. The pouch cell is “ideal” for Porsche’s concept of a “functionally integrated battery,” says Maximilian Müller, who is responsible for the Cayenne’s energy system as project manager. The six modules are the stable part of the battery, which absorb energy in the event of accidents, for example. In cell-to-pack concepts, the cells themselves are also part of the supporting structure, which is why they require a solid housing – i.e. prismatic cells or cylindrical cells. Since the module housings at Porsche absorb all forces, pouch cells are sufficient on the inside – with their thin foil bags, they offer better space utilisation than battery cells with a rigid housing.

When electrive asked why Porsche is now switching to the pouch format, Müller replied that this specific decision had already been made “before the strategic change of direction within the Group.” The prismatic standard cell was introduced in 2021, so Porsche is likely to have decided on this battery concept for the Cayenne as early as 2019 or 2020.

Not only is the format of the cells changing, but also their content. The Macan unveiled in 2024 uses NMC811 cells from CATL, i.e. with a mixture of nickel, manganese and cobalt in a ratio of 8:1:1 in the cathode, and with a pure graphite anode. In the new Cayenne, both the anode and cathode are new: six per cent silicon oxide is added to the graphite in the anode, which increases the energy density and charging capacity. For the cathode, Porsche is now using NMCA cell chemistry, which also contains aluminium. This is meant to increase the electrical stability and service life of the battery. At the same time, the nickel content has been increased to 86 per cent. Müller refrained from revealing the exact composition. At this point, all he will say is: “The 811 logic no longer applies.” The developer emphasises, however, that aluminium has the smallest share: it must be well below five per cent.

The cells themselves are designed for discharge currents of up to 1,000 amps and charging currents of up to 500 amps. Their cell chemistry gives them seven per cent higher energy density than NMC811 variants. In combination with the battery design based on the ‘module to car’ approach, this ensures that the entire battery in the Cayenne E4 has 103 litres less volume than in the J1PA, i.e. the Taycan facelift. The latter has a 105-kWh battery, of which 97 kWh are usable. In terms of dimensions, the Cayenne battery is smaller, but with better utilisation of this volume, it can hold 113 kWh (108 kWh net).

As with the Macan, there will only be this one battery for the Cayenne, with no signs of planning a smaller basic battery. Porsche will only reveal the range possible with the 108 kWh of usable energy content at the world premiere. That said, the Zuffenhausen-based company’s focus for fast travel in electric cars is not necessarily on long ranges anyway. Porsche is prepared to sacrifice some efficiency and range for performance. To ensure that its electric cars can still make long journeys as quickly as possible, Porsche always focuses on high charging capacities and short charging times, which brings us to the next topic here.

Charging

Porsche already mentioned the maximum charging power of 400 kW during the first prototype test drives. This is a very good figure and, almost logical considering the 270 kW of the Macan (without silicon in the anode) and 320 kW of the Taycan facelift (with silicon). And since BMW also achieves a peak of 400 kW in the significantly cheaper iX3, Porsche cannot afford to be outdone in terms of this value, which is important in terms of external perception.

Even so, as Müller explains, Porsche’s charging strategy is not aimed at always achieving 400 kW on the charging station display, but rather at achieving the shortest possible charging time for customers. The Cayenne is expected to complete the usual standard charging process from ten to 80 per cent in “under 16 minutes,” according to a data sheet provided in Leipzig. This puts the Cayenne well ahead of the iX3, which has a slightly smaller battery (108 kWh gross) and takes 21 minutes to charge to the same level, consuming slightly less energy in the process.

This is thanks to the Cayenne’s charging curve: even at five per cent, it can draw significantly more than 300 kW of power. From this already very respectable starting level, the charging curve continues to rise slowly as the charge level increases until the maximum is reached at just under 55 per cent, at which point the cells are in the range of 50 to 55 degrees and cannot continue to absorb these high currents. With these values, it is easy to imagine that charging from 10 to 55 per cent takes only a few minutes. After that, the charging power drops to a level of over 250 kW, which is maintained up to 70 per cent. From then on, the power drops continuously – but at 80 per cent charge, more than 150 kW still flows into the battery. And in less than 16 minutes, over 75 kWh have been recharged – which, purely mathematically, makes an average charging power of 281 kW for the entire standard charging window! Even in 2025, many electric cars can’t achieve this, even briefly, at peak times.

This charging curve is optimal for charging from ten to 80 per cent, i.e. when starting with a very low charge level, but the charging curve is not a fixed maximum that is always limited to 55 per cent. If the fast-charging process starts at a higher charge level of, for example, 30 per cent, the battery has not yet reached its upper temperature limit at a charge level of 55 per cent. “Then it is possible that the 400 kW will still be available at 60 or 65 per cent,” explains Müller. “The temperature is the decisive factor.” Of course, this also applies to cells that are too cold, in which case the power must also be reduced.

The best possible charging behaviour should be possible from a cell temperature of 15 degrees Celsius. Of course, the Cayenne also has a battery preconditioning system that automatically brings the battery to the correct temperature range via planned stops at the fast charger in the vehicle’s route planning function. Since this already starts at 15 degrees Celsius, it is faster and requires less energy in winter, for example.

Behind these charging capabilities and robust charging behaviour lies not only the new cell chemistry but also sophisticated thermal management. Each of the six battery modules has two cooling plates, whereby the system is not controlled separately in each module, but centrally. “The decisive factor for performance was the step of dissipating heat simultaneously from above and below with two cooling plates,” says Müller.

Optimum battery cooling is not just a matter of moving as much coolant as possible through the two plates. The temperature in the modules must be as uniform as possible – and this is where it gets complicated. Heat flows through the Cayenne’s cooling plates from the passenger side towards the driver’s side. This means that the coolant flows in on the right-hand side in the direction of travel and out again on the left-hand side towards the heat exchanger. If the cooling channels were completely identical, the coolant on the passenger side would have a significantly greater cooling effect than on the driver’s side, where the coolant arrives already warmed up. The temperature difference between the coolant and the battery would no longer be as great as on the passenger side, and the cooling effect would be correspondingly lower, so the battery would have a very uneven temperature.

That’s why Müller and his team have optimised the cooling plates specifically for their battery: at the front on the passenger side, the cooling channels are straight and parallel for fast flow. The closer they get to the driver’s side, the more branched the cooling channels become in order to extend the contact time. The warmer the coolant gets, the longer it takes to absorb and dissipate the same amount of heat energy. What starts as simple cooling channels under the passenger seat becomes almost a geometric work of art on the driver’s side. This is how Porsche achieves the ‘perfectly homogeneous temperature distribution,’ as Müller points out.

But the absorbed heat has to go somewhere. To cool down the coolant from the battery, the drive units (the hoses to the heat exchanger of the rear electric motor run centrally across the battery to the rear) and all other thermal systems on board, two large fans are installed in the bodywork in front of the front wheels. ‘Here, we switch from classic suction fans to pressure fans,’ explains Müller. This means that the air is no longer drawn into the radiator but pressed in under pressure. This is said to be 15 per cent more efficient.

And despite its higher efficiency, the pressure fans can sometimes become a little louder. They also have to move considerable amounts of air to ensure the cooling capacity required in the vehicle – at least during fast charging, and even more so in warm conditions. What is not a problem at the HPC at a motorway service station or in a charging park in an industrial area can be disruptive elsewhere. For example, at fast chargers in supermarket car parks that are close to residential buildings. Enter the ‘quiet charging’ mode. This reduces the fan speed and makes the car quieter during fast charging. Since the full cooling capacity is then not available, the charging power must be reduced if the battery gets too warm. Müller does not want to reveal any figures here but insists that the power will not be “extremely capped.” Only tests or reports based on customer experiences will show how the Cayenne behaves in this ‘quiet charging’ mode.

Another noteworthy aspect of charging is that, as with the Macan, Porsche has implemented what is known as ‘bank charging’ for fast chargers with a maximum of 400 volts. This involves virtually dividing the car’s 800-volt battery into two 400-volt batteries that can then be charged in parallel (in the Macan, the right and left modules were separated, while in the Cayenne, the front three and rear three modules each form a ‘bank’). Under optimal conditions, the battery can then be charged from ten to 80 per cent in 26 minutes at 200 kW, which is a very good value for a 400-volt system with 108 kWh net.

Porsche presented an inductive charging system at the IAA in Germany this year. This wireless charging system will first be offered for the Cayenne, but we won’t go into detail about that here, as we described the system in more detail in this article. Suffice to say that the surcharge for this feature is expected to be around £6,500. Those who want to charge the battery at 11 kW more cheaply, but with minimal extra effort, can do so at no extra cost with the AC cable. A 22-kW onboard charger is expected to follow later but is unlikely to be available at launch.

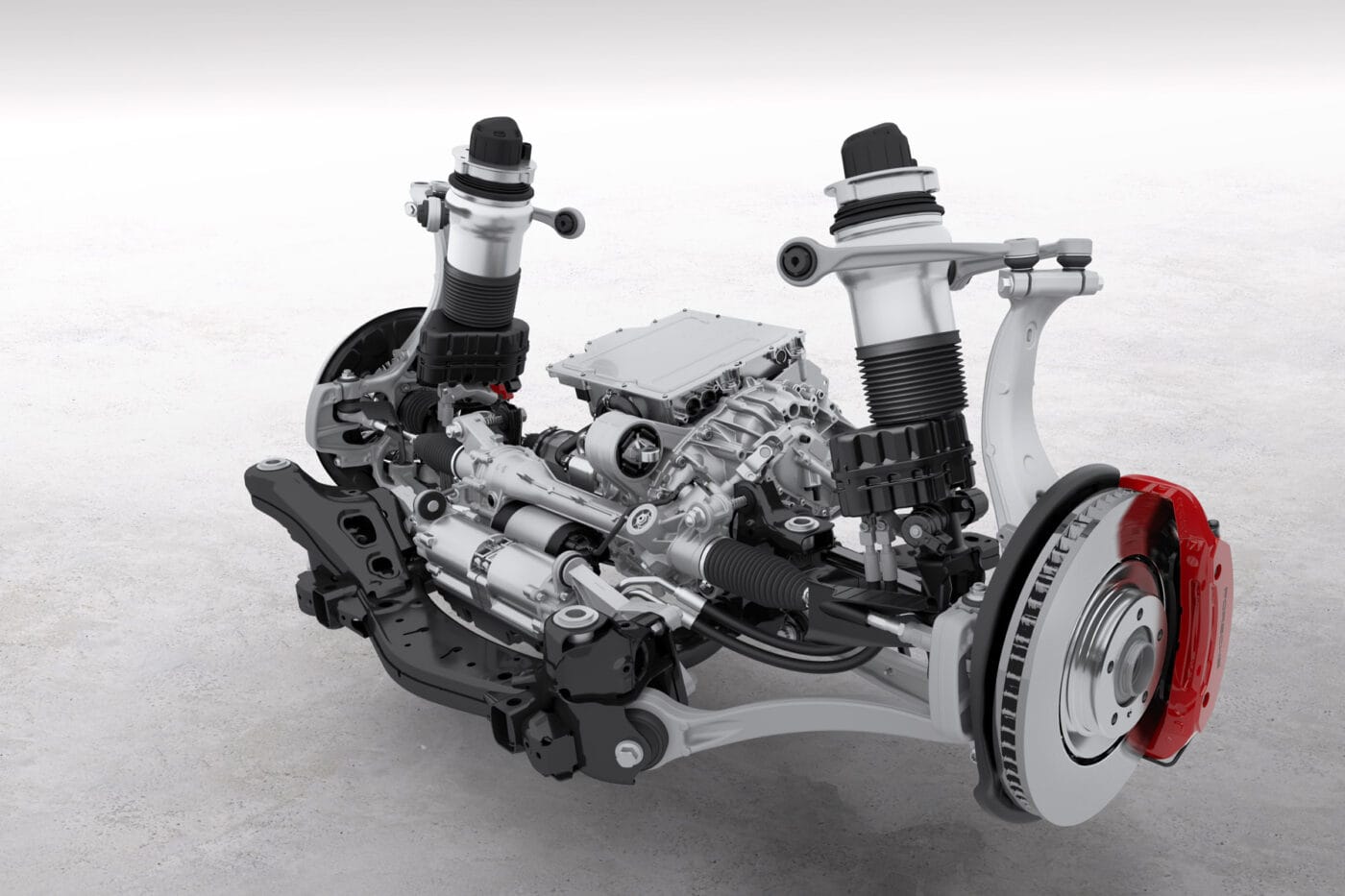

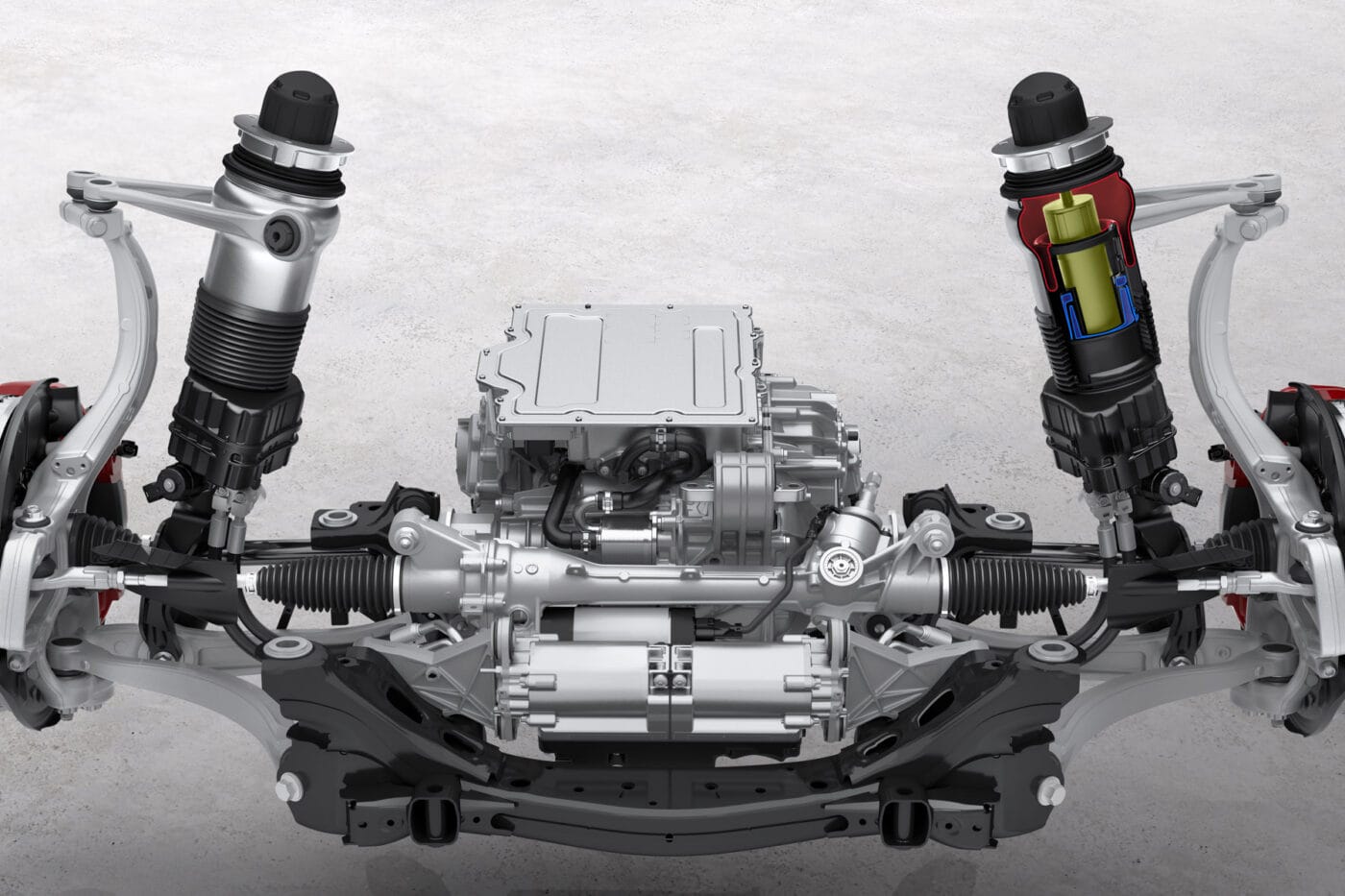

The suspension

The chassis isn’t really our area of focus at electrive, but it’s worth mentioning in relation to the Cayenne E4 for several reasons. Firstly, Porsche Active Ride is the first active chassis in an SUV that goes far beyond the functional scope of conventional air suspension. Secondly, Porsche develops its chassis in conjunction with the drive systems right from the outset. “There is no longer a clear distinction between the chassis and the drive system in development work,” says Timo Henn, who joined Vivien Schreiber at the Leipzig technology workshop in presenting the ‘driving system’ – a combination of the drive system and the chassis.

The Cayenne comes with conventional air suspension as standard, with familiar features such as different ride heights for sport and off-road modes and varying degrees of damping. Porsche Active Ride supplements the air suspension with actively controllable elements that can be moved within a very short time. The system calculates the optimum settings every millisecond. It can take up to 34 milliseconds for an impulse to be implemented and pressure to build up. This still allows for extremely fast actions and a high level of comfort.

The actuators work so quickly – and ‘prepare’ the spring-damper unit on each wheel for that particular pothole, i.e. to take active measures – that Porsche does not need to use cameras to monitor the road in order to detect potholes, as some of its competitors do. As soon as the Cayenne detects that a wheel is driving into a pothole, this is calculated and the corresponding suspension actively pushes the wheel into the pothole, so to speak. The unevenness is absorbed, the vehicle structure remains completely stable – and, in the best-case scenario, the occupants feel nothing.

For the first time in the Cayenne, there is also a ‘Comfort’ driving mode to take full advantage of these active suspension functions. This keeps the body stable in as many driving situations as possible; the car does not dip at the front when braking or on uneven surfaces, and it does not lean to the side when cornering – which would also be the case in ‘Normal’ mode. In Comfort mode, these movements are even overcompensated, meaning that the car does not lean naturally outwards in a fast corner, but actually leans slightly into the corner. This is designed to make the Cayenne even more comfortable for its occupants. This overcompensation can also be deactivated on request, separately for pitch and tilt.

But Porsche wouldn’t be Porsche if it suddenly became all about comfort, which is important, but not the only thing. In the familiar ‘Sport’ and ‘Sport Plus’ driving modes, the Active Ride System can also be used to keep the vehicle as stable as possible, for example, when braking or accelerating. The launch control start, which Porsche development drivers demonstrated to their passengers on the Leipzig test track, was impressive in terms of pure acceleration, but the car does not lean back nearly as much as one would expect when an SUV weighing over 2.5 tonnes is catapulted to 100 kph in less than three seconds.

With its enormous control speed, the active suspension can also be used to specifically increase traction in certain situations when driving sportily. The suspension then works in such a way that the car is actively pressed to the ground when cornering and/or braking. The result is cornering speeds that even those with a lot of experience in the automotive industry would not have thought possible in an SUV. The way the driving system, software, hardware and tyres work together here is certainly impressive.

Although it may not be that important to many Porsche customers, the Cayenne also has an off-road mode that benefits from the new chassis. With its active elements, the Cayenne does not need classic stabilisers. This significantly increases the maximum axle articulation beyond the level of the current combustion-engine Cayenne. And since the drive forces can be readjusted within five milliseconds, you don’t even notice when a wheel loses traction or hangs in the air on the Leipzig off-road course in the Cayenne E4. The Cayenne redistributes the drive force and simply continues to roll steadily on.

The digital features

The days when a technically outstanding drive system was enough to make a car a sales success are long gone. The Taycan also looks impressive on paper and has beaten the competition in many tests. However, sales figures are still below expectations. This is because demand has shifted significantly – albeit to varying degrees globally – and other features have become important or, in some cases, even more important, like connectivity and digital offerings.

This is not our area of expertise at electrive, but it is part of the Cayenne E4 and will also be important for the rest of the Zuffenhausen-based company’s model range. “What is being introduced in the Cayenne will follow in all models and markets in the coming months,” announces Ivo van Hulten, Director of Driver Experience Design. Although the Cayenne systems are based on what Porsche introduced with the Macan – such as Android Automotive OS as the operating system and an architecture with five central computers – they go further in some respects.

Particularly noteworthy is the new ‘Flow Display’, which van Hulten describes as the largest display ever seen in a Porsche. The screen area is said to be 50 per cent larger than in the current Cayenne E3. The ‘Flow Display’ is the new centre screen, the central touchscreen for infotainment. In the Taycan, Porsche integrated a second, inclined touchscreen at the bottom of the centre console, for climate control, for example. In the Cayenne, this second touchscreen virtually merges with the central display: the Flow Display, with its curved glass, extending from the dashboard into the centre console.

The carmakers from Zuffenhausen are rather proud of the “balance between the analogue and digital worlds” (quote from van Hulten). Not everything is operated via the new touchscreen with its curved glass: there are still a few haptic elements at the bottom for volume and climate control. Porsche also conceptually divides the Flow Display into two areas: the ‘stage’ with the upper part and the ‘terminal’, i.e. the curved lower part. This comes towards the driver, making it easy to operate without having to stretch. The new bracket, as a hand rest (replacing the old gear lever, so to speak) is designed to make operation even easier.

The stage is used to operate navigation, music, and so forth, as before, but there are also views in which the display extends beyond the bend to take up the entire screen. The most frequently used variant will probably be the one in which both are visually separated, when the ‘terminal’ at the bottom is used precisely for that purpose. This is made possible by new widgets that can be operated like speed dial elements. Examples include searching for a suitable charging option with just one click, accessing the calendar or – my favourite after my initial experiences – the ‘personal settings’. These can be called up with one click and confirmed with a second click – as required by EU regulations. In these personal settings, you can specify which features and assistance systems you would like to use, some of which must be activated each time the vehicle is started. So, for example, if you want to switch off the speed limit warning and lane departure warning systems but prefer to use the emergency brake assist and driver attention alert systems, you can save this setting and activate it with the two clicks mentioned above before setting off – instead of having to switch off the unwanted assistance systems individually in their submenus.

For long journeys or charging breaks, Porsche is not only expanding the range of apps available in the Macan via the App Store, such as streaming services including Spotify, Amazon Music and others, or news apps. Porsche is also entering the gaming sector and has entered into a partnership with AirConsole. This will enable games to be played via the vehicle system using the touchscreen, a connected smartphone or even a Bluetooth controller. And so as not to disturb the driver, audio can be output via wireless headphones. Porsche is also venturing further in terms of system design. Those who don’t like the typical Porsche black and grey colour scheme of the screens can now choose between five themes, such as a subtle green or a bright neon pink.

The new display architecture, which can also be supplemented with an additional screen for the front passenger, naturally also has an impact on the interior design. “A Porsche cockpit will always be driver-oriented, with the instruments positioned at the highest point of the dashboard,” says interior designer Markus Auerbach. “It was important to us to integrate the display into the dashboard rather than just placing it on top.”

As a result, there is no longer any space where the air vents are usually located in a Porsche – namely between the infotainment touchscreen and the climate control – because the terminal of the new Flow Display protrudes into this area. This meant that the air vents had to be relocated and are now positioned above the display in the dashboard for the first time. According to Auerbach, discreetly hiding them was not an option. “Customers from hot countries have different preferences than we Central Europeans. For us, it has to be as draught-free as possible,” says the designer. “In other countries, however, it is extremely important to be able to feel the cold air blowing directly on you.”

First, the drive systems, then the battery and charging behaviour – none of this is enough if the software does not meet customer requirements. Or if even a mundane ventilation outlet is not positioned correctly. Even after its world premiere at the end of the year, it will still be impossible to say for sure whether and how the electric Cayenne will win over customers. That will only become clear in 2026, when the first vehicles roll off the production line in Bratislava and into customers’ hands.

This article by Sebastian Schaal was published simultaneously on our German platform electrive.net. Carrie Hampel translated the text.

1 Comment