Dürr presents new electrode dry coating technique

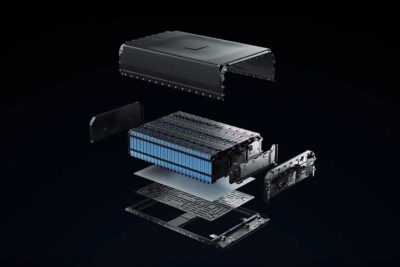

With X.Cellify DC, Dürr has developed a new type of dry coating for electrodes: it creates a free-standing film of active material that can be returned to the process 100 per cent until it is laminated onto the collector foil. This significantly reduces waste.

Specifically, the new method does not require solvents or drying ovens, which are both environmentally taxing and energy-intensive, as the Dürr method produces the electrodes from a dry powder mixture. As the German company writes: “The dry battery material is pressed into a film using the Activated Dry Electrode process by development partner LiCAP Technologies. The new X.Cellify DC development covers all process steps – from dosing, film formation, and densification to lamination onto the collector foil.”

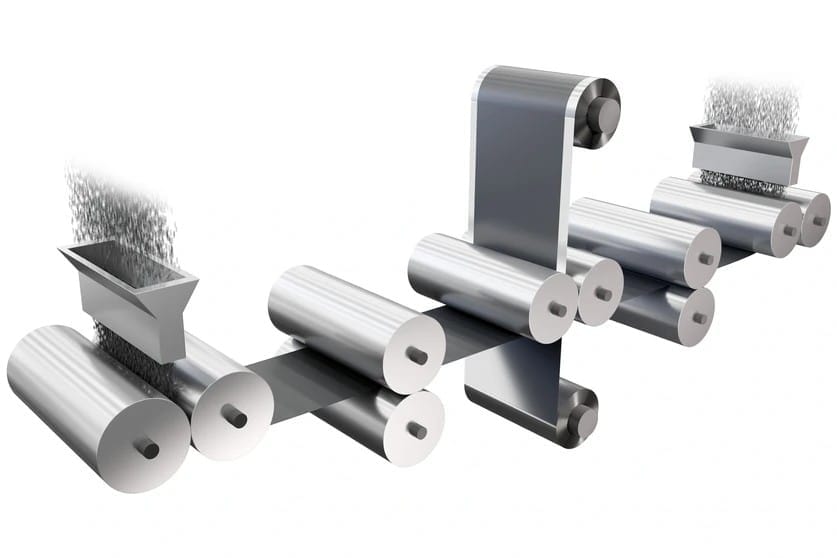

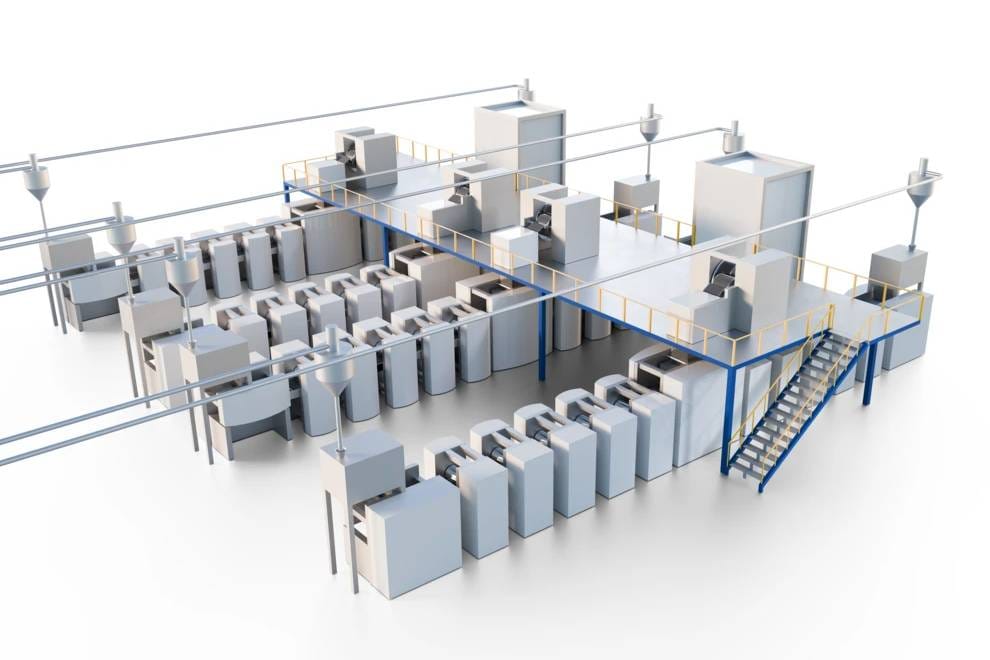

In essence, this will allow manufacturers to reduce space requirements by up to 65 per cent and lower energy consumption by an impressive 70 per cent. So far, this has only been realised in a proof-of-concept plant in Chassieu, France, where a dry room environment was set up with ‘calendar’ technology. These ‘calendar’ machines are rollers that compress materials into an even layer, which also marks the start of the production process: “Dry coating starts with film formation: A horizontal calender forms the dry powder into a film.”

In the next step, more rollers compress the film into the required layer thickness, density, and porosity. Finally, the film is then laminated onto the collector foil from each side, producing the electrode. As the carrier foil is only needed in the final step, it can be reused in the process, Dürr explains.

According to Dürr, the proof of concept for the process shows that the technology works reliably and is scalable. At the moment, the technology is designed to work with lithium-ion batteries, but in future, solid-state batteries are also envisioned. The next step remains setting up pilot projects on a gigawatt scale.

“The successful proof of concept is a major step forward for us. We have demonstrated that the new kind of dry coating with free-standing film works reliably and delivers consistently good quality,” says Bernhard Bruhn, Vice President of Dürr’s Global Business Unit LIB, adding: “It can be scaled up, making it the basis for initial pilot projects in industry.”

The plan to find production partners is already underway, as Bruhn emphasised: “To take the next step, we are actively seeking pilot partners in the industry for gigawatt-scale projects. This will enable us to bring the technology into real production environments – whether for electric cars, stationary storage or other applications.”

Dry coating is becoming increasingly popular, as manufacturers seek to lower battery production costs and their environmental footprints. For example, Volkswagen subsidiary PowerCo presented a dry coating process in 2023, with plans to commercialise the process by 2026. Tesla was also looking into the technology in the same year.

0 Comments