PEM presents virtual model for optimising battery cell production

The PEM Chair has been working on the digitalisation of production processes for several years. The solution now being presented, which focuses on cell production, was unveiled at a conference in New York State in July and, according to RWTH Aachen University, has now been published as a freely accessible paper in the scientific journal ‘Robotics and Computer-Integrated Manufacturing’. The title: ‘Modelling Flexible Configuration of Cell Finishing for Future Battery Production Research’.

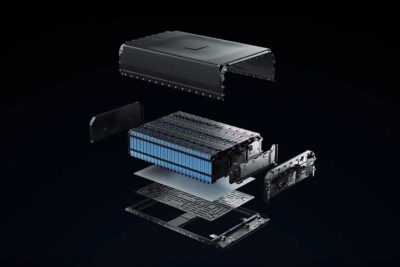

The modelling presented by the Aachen scientists is specifically geared towards cell finishing as a particularly energy-intensive process in battery production and, based on real industrial data, provides eight plant configurations that can be implemented in large-scale cell production. PEM Director Professor Achim Kampker emphasises that no systematic approach to configuration design has yet been established in the industry: “The numerous interrelationships in the product and production system, as well as the continuous development dynamics, are hardly taken into account in the current planning of cell finalization so that no systematic approach to configuration design has yet been established,” Kampker points out.

The publication, which was overseen by the PEM Chair, now points to a wide range of possibilities for configuring plants, with the paper stating that the more sustainable solutions can reduce production costs and thus also promote competitiveness. The main task of the researchers in the run-up to the publication was to use analysed raw data to build a structured database of products, processes, parameters, plants and their interrelationships. The paper now published is based on the results of the FoFeBat2 project initiated in 2021.

In this project, the Aachen-based institution focused, among other things, on the digitalisation of production processes in order to contribute to the establishment of the Fraunhofer Research Production Battery Cell FFB in Münster. This explains why RWTH Aachen University announced in the recently published paper that the new modelling is primarily intended to serve the dynamic configuration of cell production in the Research Production Battery Cell FFB.

“Cell finalization is still characterized by enormous challenges, which are reflected in cell-specific plant technology, long process times, and massive energy requirements,” summarises author and PEM expert Sicong Deng. Virtual modelling enables flexible and efficient production development and optimisation in industrial cell finalisation, as well as the integration of technological innovations.

pem.rwth-aachen.de, sciencedirect.com

This article was first published by Cora Werwitzke for electrive’s German edition

0 Comments