PEM project to speed up battery development

To test their module-to-chassis concept, the researchers built ten vehicle bodies with an integrated structural battery system, which were then subsequently tested by project partners TÜV Rheinland and Magna. Additionally, the team “also designed several simulation models and successfully validated them through testing.”

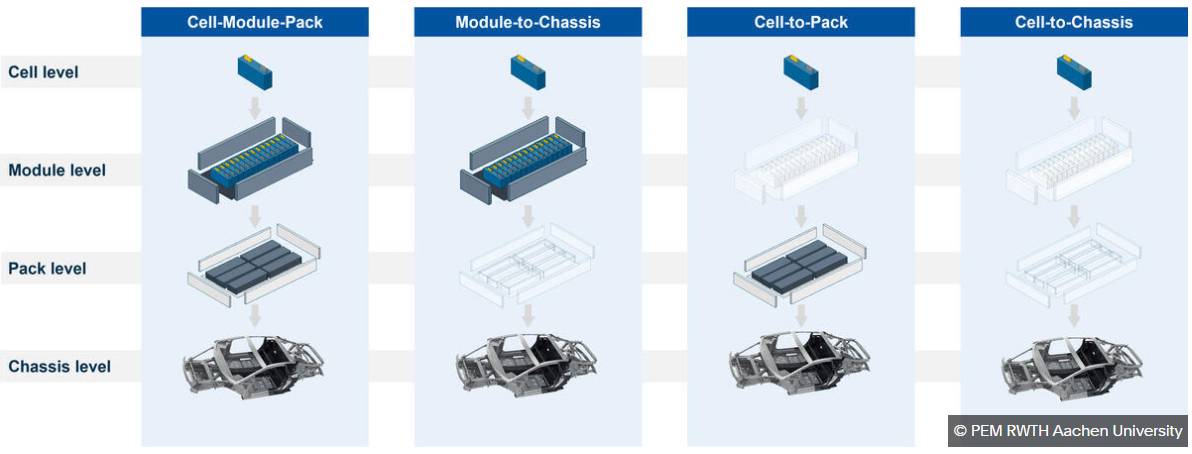

The choice to use a cell-to-pack approach had several reasons, as it would “increase both the mass-related and the spatial energy density of batteries.” This then would allow for efficiency increases up to 20 per cent, as well as cutting costs by reducing the complexity and number of components, compared to a basic tripartite structure, which contains battery cells, the modules and the pack.

During the three-and-a-half-year project, which was funded by the German Federal Ministry for Economic Affairs and Energy, industrial partners such as Ford and Trumpf worked on developing structural battery systems and reducing their production costs for earlier market entry.

The goal was to increase both the mass-related and spatial energy density of batteries in the future. In the course of the project, key guidelines and findings in the field of battery safety were also developed, which were published in the form of a ‘Methodology for Analyzing Changes to Battery Systems and Evaluating the Resulting Testing Requirements’.

“Early validation of battery systems using artificial intelligence helps to reduce critical errors in the production process and lower the costs of prototypes,” said PEM Director Professor Achim Kampker. Their approach relied on virtual validation testing, which, the researchers say, significantly reduced the number of battery tests required during the process.

In the project detail description, the initiators praise the potential of using AI in the development process: “Early validation with the help of artificial intelligence can reduce errors that are crucial for the subsequent production steps and lower prototype costs. This is made possible by saving test times, which results in faster development of new types of battery systems and thus earlier market entry.”

PEM Management Member Professor Heiner Heimes added: “The time saved on testing allows for faster development of innovative battery systems and, as a result, earlier market launch.”

pem.rwth-aachen.de, pem.rwth-aachen.de (project details)

0 Comments