German BAM says sodium-ion batteries require new safety mechanisms

According to the BAM, the investigations have shown that proven safety mechanisms are not automatically equally effective for all battery technologies, but should be specifically adapted to the chemical composition and cell design of new batteries. Due to their resource-saving materials and potential cost advantages, sodium-ion batteries are considered a promising alternative to lithium-ion systems. What’s more, sodium-ion cell chemistry is also considered to be quite safe.

For this reason, the Federal Institute for Materials Research and Testing has compared the safety of three different types of batteries. In addition to sodium-ion cells, the tests also examined lithium-ion batteries with nickel-manganese-cobalt cathodes and lithium iron phosphate cell chemistry. NMC cell chemistries are currently used primarily in electric cars and portable devices (such as smartphones), while LFP cell chemistry is often used in stationary storage systems – but also increasingly in electric cars. Specifically, NFM cells (sodium-ion cells with nickel, iron and manganese), NMC532 cells and LFP cells were examined – all of them cylindrical cells in the 18650 format.

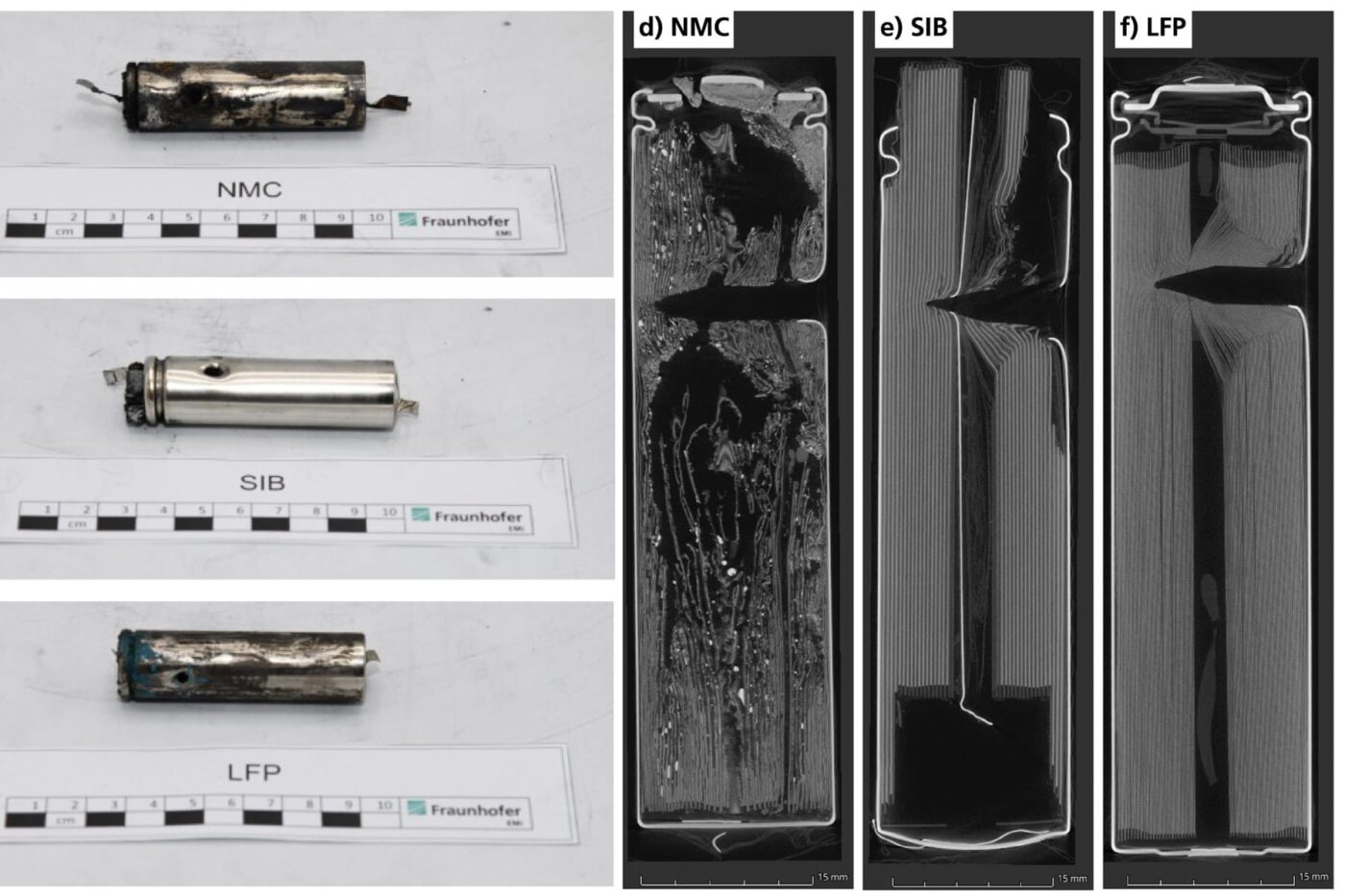

In the investigations, mechanical damage to the battery cells was simulated using a nail penetration test – the cell is pierced with a metal pin to ‘trigger a critical damage event’, as the BAM puts it. This usually triggers an internal short circuit in the cell, which, together with the mechanical damage, can lead to thermal runaway of the cell. Here, the BAM wanted to investigate how the sodium-ion cell behaves in comparison to the more familiar cell types and whether the built-in safety mechanisms are effective. Using high-speed X-ray imaging in a test chamber specially developed by the Fraunhofer Institute for High-Speed Dynamics (EMI), researchers at the European Synchrotron Radiation Facility in Grenoble were able to visualise the internal processes in sodium-ion batteries during a critical event in real time for the first time.

The tests revealed significant differences in behaviour. The tests on lithium-ion batteries, on the other hand, went as expected. “The lithium iron phosphate battery proved to be particularly stable. The lithium-ion battery with a nickel-manganese-cobalt cathode reacted in a controlled manner – its safety mechanisms worked as intended,” reported BAM. The behaviour of the sodium-ion cell, on the other hand, is described as “surprising” because it led to “an almost explosive reaction.” However, the classification that followed immediately afterwards, which the experts were able to make thanks to the complex high-speed X-ray images, is important: the cause of this process was not the cell chemistry itself, but the structure of the tested cell – specifically, ‘a failure of the cell’s venting system’.

This system is actually designed to ensure that, in the event of a thermal reaction inside the cell, the excess pressure caused by the gases produced is reduced by targeted venting. “However, due to the rapid increase in pressure, the venting system was blocked by other components of the safety equipment, which led to the abrupt and violent reaction,” according to the Federal Institute.

“Our investigations show that safety mechanisms cannot simply be transferred from one battery technology to another,” explained Nils Böttcher, head of the BAM battery testing centre. “Especially with new battery types such as sodium-ion cells, mechanical components such as venting systems must be specifically adapted and tested. Our findings do not call into question the fundamental safety of sodium-ion technology, but they do underscore the need to consider chemical composition and safety design together.” BAM is therefore actively involved in the development of standards and norms in the field of sodium-ion battery safety.

The results were also published in issue 36 of the Journal of Power Sources Advances. Slow-motion video recordings of the tests can also be found there, showing exactly how the components inside the sodium-ion cell behave before the explosive damage occurs.

bam.de, sciencedirect.com (both in German)

This article was first published by Sebastian Schaal for electrive’s German edition.

0 Comments