Will Tesla make own batteries with Maxwell tech?

With technology gained through acquiring Maxwell Technologies, in future, Tesla could produce its own battery cells instead of relying on Panasonic. This can be gleaned from comments from Elon Musk, JB Straubel and Drew Baglino at Tesla’s recent general meeting.

At the general meeting this month, Elon Musk hinted that scaling of battery production to keep up with demand was currently limiting Tesla’s growth: “As we scale battery production to very high levels, we have to look further down the supply chain and we might get into the mining business… I don’t know. A little bit at least. We do whatever we have to to ensure we can scale at the fastest rate possible.” But when it came to battery production, he didn’t seem to want to let the cat out of the bag. He simply stated that more would be announced during the “Battery and Powertrain Investor Day” that Tesla is planning before the end of the year.

CTO JB Straubel said that Tesla needed a “solution” to “large-scale solution for battery cell production,” but did not confirm their plans in this regard. Drew Baglino, vice president of technology, added that they wanted to be “master of their own destiny”.

Furthermore, Musk briefly mentioned the integration of the battery technology recently acquired from Maxwell after the Californian company’s recent takeover of Maxwell Technologies. “We think this is really quite strategic [..] this is a very important technology that will have big effect on the cost and scale of cell production – both reducing the cost and capital required to scale cell production.”

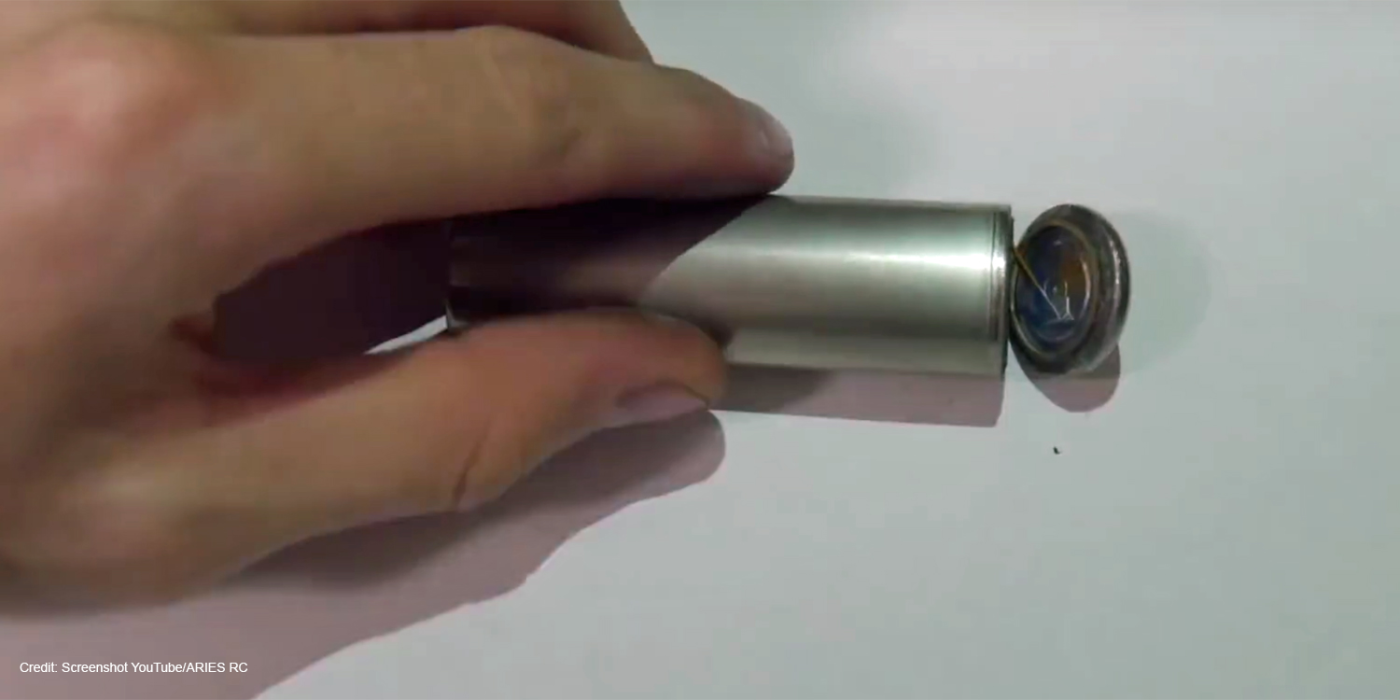

Until now, Tesla has been dependent on its partner Panasonic for battery cells. The 18650 cells for the S and X models are supplied by Panasonic, while the newer 2170 cells for the 3 model are manufactured by Panasonic at Gigafactory 1 in Nevada. Here, although the production takes place together in one large hall, Panasonic’s cell production facilities and employees belong to Panasonic. Only when the cells have been officially handed over to Tesla, do other employees and machines take over the further processing into battery packs for the electric cars.

In the middle of last year, Panasonic said it was planning to increase production capacities in Tesla’s Gigafactory 1. But in a strange turnaround in April just passed, according to a Nikkei report, Panasonic and Tesla’s plans to increase production capacity for battery cells at Gigafactory 1 were put on ice due to financial problems at Tesla and uncertainties about future demand. While this is making industry players wonder, Panasonic has now taken a very ambivalent stand.

It is certainly true that recently-acquired Maxwell Technologies could help with the possible in-house production of battery cells. For some time now, Maxwell has been working on so-called “dry electrodes” that do not require solvents and are designed to significantly improve the performance of lithium-ion cells and reduce production costs. Demo cells that have already been developed with an energy density of over 300 Wh/kg and a potential of over 500 Wh/kg.

A patent application from Canada shows just how much Tesla is already researching battery cells. It deals with a new way of analysing the electrolyte in a lithium cell. The aim is to prevent the failure of individual battery cells. The patent was filed by Jeff Dahn, head of Tesla Canada Industrial Research.

Tesla batteries are apparently already ahead in terms of price and quality. Analysts from UBS teamed up with engineers to figure out which electric vehicle batteries made by established manufacturers offer the best value. They concluded that cells made by Panasonic in Tesla’s Gigafactory are 20 per cent more cost efficient than the next best on offer from LG Chem.

electrek.co, electrek.co (patent registration)

0 Comments