Lifecycle assessment: Electric cars vs ICEs

Is an electric car more climate-friendly than a vehicle with a combustion engine or not? And if so, under which conditions is that the case? A team at the Environment Campus Birkenfeld in Trier now published a new study – not using metadata, but real-world tests and measurements. The results are remarkable.

* * *

There is much discussion on the “real” environmental impact of electric cars over their lifecycle. The figure of 17 tons of CO2 for an EV battery is still haunting the internet, perpetuated often enough by fossil-fuel related industries. Besides, there are countless other surveys, sometimes more, sometimes less scientific claiming to establish at which point an electric vehicle trumps a combustion vehicle in lifetime impact. But they all have on thing in common, they use metadata.

“There are very few projects with original data, especially from Germany,” says Eckard Helmers from the Environment Campus Birkenfeld at Trier University of Applied Sciences. For this reason, the professor from the Department of Environmental Planning & Technology has chosen a different approach with his two co-authors Johannes Dietz and Martin Weiss: A comparative lifecycle assessment (LCA) of cars with electric drives and combustion engines, based on conditions that come as close as possible to the real world. For the work entitled ‘Sensitivity Analysis in the Lifecycle Assessment of Electric vs Combustion Engine Cars under Approximate Real-World Conditions’, the researchers collected as much data as possible themselves – by dismantling a VW Caddy with a 1.6-litre petrol engine, analysing it and rebuilding it with an electric drive. They call it cradle-to-grave inventories. There’s a free link to the complete study at the end of this article.

The result of years of work is complex and can hardly be expressed in a single figure or statement. However, we liked this one: Producing batteries with photovoltaic electricity instead of Chinese coal-based electricity decreases climate impacts of battery production by 69%. However, there are more complex examples at play as the team took into account the energy mix and battery production. So the infamous “break-even mileage”, at which an electric car has a more favourable eco-balance (in the German sense of Ökobilanz for LCA) than the internal combustion engine, has of course been calculated by the researchers – but in different scenarios. If the converted e-caddy – its 25.9 kWh battery was produced using wind power – is charged only with green electricity during its service life, the electric car is “cleaner” than its fossil fuel-powered counterpart after just 17,000 kilometres. A vehicle with a battery twice as large (51.8 kWh) can reach values between 20,000 (battery made from wind power) and 35,000 kilometres (battery made from coal power) until break-even when charged with green electricity. If, however, charging with an electricity mix that roughly corresponds to the current European average, even a car with a small battery will break even only over or under 50,000 kilometres – depending on whether one assumes second-life use or not. An electric vehicle with a 51.8 kWh battery, which is produced using coal-fired electricity and charged using the “dirty” electricity mix, only reaches break-even after 310,000 kilometres.

The range is enormous – so not all-electric cars are the same. In one case, one may reach the point of break-even quickly; in another case, the mileage is so high that only a few vehicles will achieve it. How did the researchers around Helmers come up with these figures?

More exact data through real-life measurement?

All begins with production, and in this case, the researcher’s analysis of the Caddy’s set up. Volkswagen Commercial Vehicles, for example, gives a percentage breakdown of nine material groups for the Caddy, but not their detailed composition. The researchers were able to differentiate this much more precisely – including the transport miles of individual components from their respective production sites to the plant in Poland that assembled the Caddy – the petrol engine, for example, comes from Salzgitter, the gearbox from Kassel and the starter battery from Hanover.

All of this plays a role when looking at the ecological impact of production. However, when building an electric car, the electricity for battery cell production is known to be the most significant factor. The Trier researchers modelled four scenarios: Battery cell production in China with a high proportion of coal-fired power, production in Europe with the European power mix, production with 100 per cent solar power (as Tesla promised for Gigafactory 1 in Nevada) and also with 100 per cent wind power. Although the latter option does not exist yet “it could be a future option in Europe,” as far as the researchers know.

The results show enormous differences in cell production alone. While the battery cells from China account for 1,180 grams of CO2 equivalent per kilowatt-hour, the European electricity mix still has 531 grams of CO2 equivalent. The two productions with renewable energies are much cleaner with 92 grams (solar) and 15.8 grams (wind). “In the worst case, the battery can account for 36 per cent of the total lifetime CO2 emissions of an electric car,” says Helmers. “I think one must emphasise this aspect on the eve of billion-euro investments in new battery production.”

Carbon-based electricity for battery cell production as a step backwards?

The professor here refers to the battery cell factories in Poland, for example, that make most of the cells for European electric cars. “It is very important where and with what kind of electricity the cell factories run,” says Helmers. “EU legislation currently ignores the carbon footprint of the energy supply, but this must, of course, change if we take a holistic view! Is Europe falling behind Elon Musk’s level of knowledge from about ten years ago?”

To electrify the Caddy, the Trier researchers opted for Lithium Iron Phosphate (LFP) cells from the Chinese manufacturer CALB. They installed a battery with an energy content of 25.9 kWh. They also simulated a battery twice the size with 51.8 kWh and included the original materials of the battery cells (according to the specifications of the manufacturer CALB) in the analysis. In contrast to the nickel-cobalt-manganese (NCM) technology frequently used in the automotive industry, the LFP cells do not contain cobalt with its related problems of extraction, especially in the Congo. However, according to the scientific literature, the influence of the materials is approximately the same for different cell chemistry types and it is therefore negligible whether the cell is an LFP, NCM or NCMA cell. The energy requirements for production are far more critical.

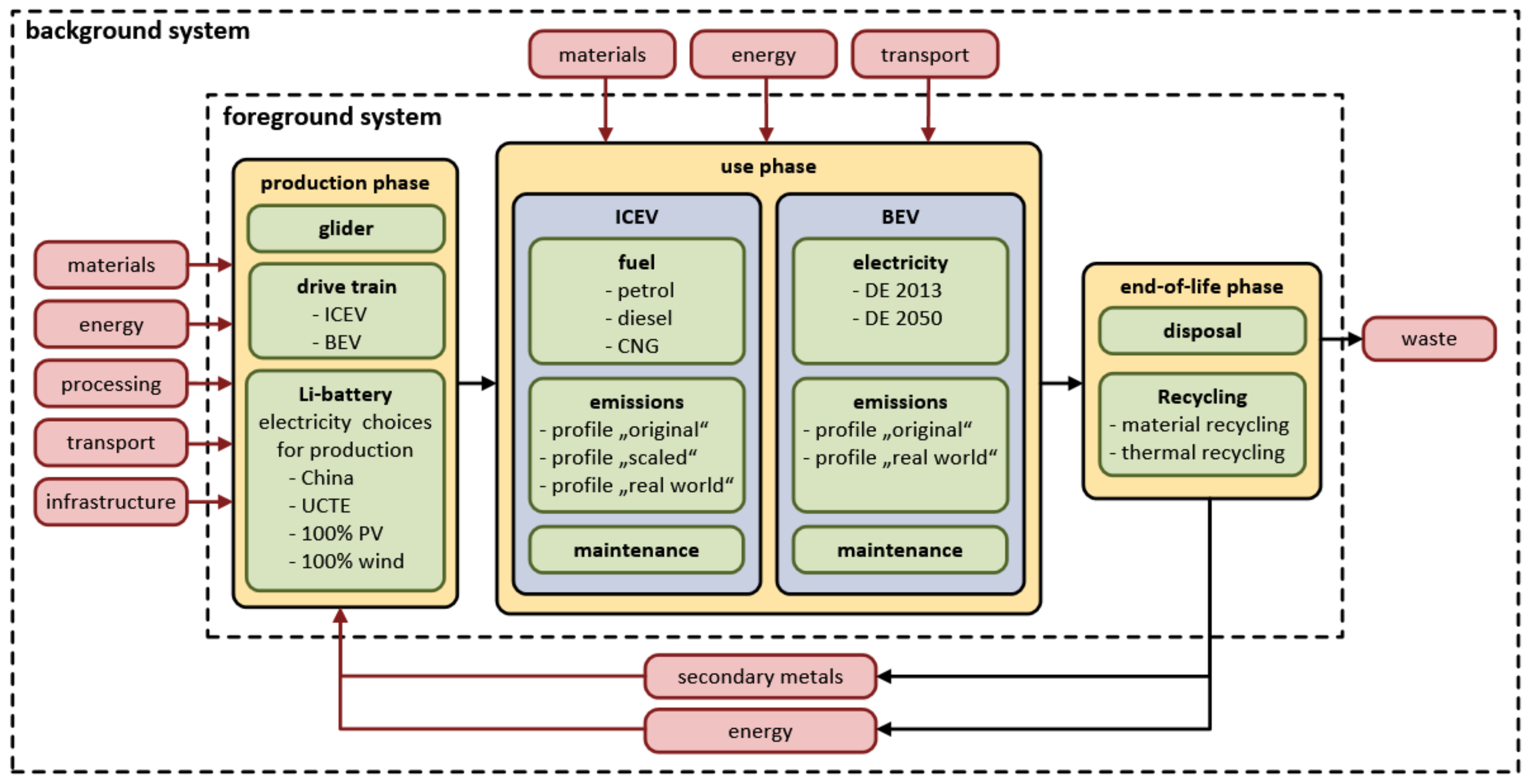

Using all this data, the researchers calculated the environmental lifecycle impact using the ReCiPe characterisation method that captures 18 impact categories. They arrived at a total of nine different emission profiles of the vehicle, from gasoline, diesel and CNG drive to the electrified variants in various battery capacity and production scenarios. The basis for this was, among other things, a measured petrol consumption of 8.89 litres per 100 kilometres before the conversion and measured electricity consumption of 23.57 kWh/100 km after conversion. The categories include the total CO2 equivalents over a lifetime of 150,000 kilometres, PM10 emissions, but also ozone release or depletion of natural resources in kilogram iron equivalents.

Electric cars do not look best in some categories

The electrified Caddy has clear advantages over the combustion models in only five of the 18 categories – namely climate change, smog formation potential, depletion of fossil resources, natural land conversion and ozone depletion. Still, in the overall assessment of all factors, the electric cars all come off better – in two cases even significantly better. The researchers attribute this to the ReCiPe evaluation scheme that emphasises factors relating to climate change.

“For electric cars, there are some categories in which they do not look good,” says Helmers. But he also stresses that common lifecycle modelling still underestimates the environmental benefits of electric cars. For example, noise emissions from traffic are provenly harmful to people – but environmental LCA usually does not include this advantage of e-cars. Or another example: According to Helmers, printed circuit boards, as used in electronics, have a significant impact in the human toxicology category over the life of the car because of the metals they contain. In data records of electric vehicles, the relatively high proportion of printed circuit boards in the overall electronics is precisely recorded and included in the calculations. This is not necessarily the case for ICEs. Besides, the relatively conventional Caddy has far fewer of these circuit boards than a combustion engine luxury sedan with countless control units and semi-autonomous driving functions. So even among ICEs, there are enormous differences.

The evaluation shows one thing clearly, however: how important the energy source is for battery production, but also for charging during the lifecycle. If using coal-fired electricity predominantly, the electric car comes off badly in categories such as smog formation potential, particulate matter formation, land consumption or acidification of the earth – and of course in the exhaustion of fossil resources. “Switching from Chinese electricity to 100% photovoltaic reduces the impact in 14 categories by an average of 43% per impact category,” the study says. “On the other hand, when using 100% wind power in battery production, despite the impact on the depletion of mineral resources, even this impact is less than when providing Chinese electricity”.

However, direct power consumption during cell production only accounts for a part of the CO2 equivalents. And even this proportion can vary greatly – from 75 per cent in the coal-fired power scenario, 57 per cent in the European power mix, and 0.4 per cent for 100 per cent wind power. In other words, from very significant to virtually negligible. The provision of the cell components accounts for the remaining shares, i.e. between 25 and 99.6 per cent. The carbon footprint of battery production using wind power is, therefore, almost entirely dominated by the provision of the battery components. In contrast, in the case of coal-fired power, it is only a quarter of the total CO2 equivalents. All this shows how vital production with renewable energies is for environmental lifecycle assessment.

Only one mode of transport is cleaner than electric cars

Another critical point is the battery size. In a further comparative analysis, the researchers calculated the total CO2 footprint over a service life of 150,000 kilometres or 200,000 kilometres (use phase mileages), first using the German energy mix of 2013 (according to the researchers a good comparative value for the European electricity generation mix) and then a simulated energy mix from 2050 – if Germany continues to expand renewable energies.

With the fictitious 2050 power generation mix, the electric car always comes in below the combustion value calculated here at 263 grams per kilometre – regardless of whether a 25.9 or 51.8 kWh battery was the basis. Even in the “worst” EV application case with 51.8 kWh without second-life use (which saves 15 per cent on average), the simulated electric cars with a maximum of 166 grams of CO2 equivalent remain significantly below the combustion value. However, Helmers does not consider a further mathematical doubling of the battery size based on the Caddy data permissible to compare a premium class e-car. Because of the described effects of other components such as the electronics, an e-car’s LCA would need to be compared with that of a luxury car to be valid.

The situation is different when charging with the 2013 power mix, think Europe: Here – depending on the power source for battery production – electric cars with an energy content of around 50 kWh are already at or above the level of the combustion engine. Only vehicles with small batteries (25.9 kWh in the simulation) consistently perform better than the combustion engine. It is easy to see what chances such a (lower range) electric car would have in sales at present. Let’s put it this way: They would not be great.

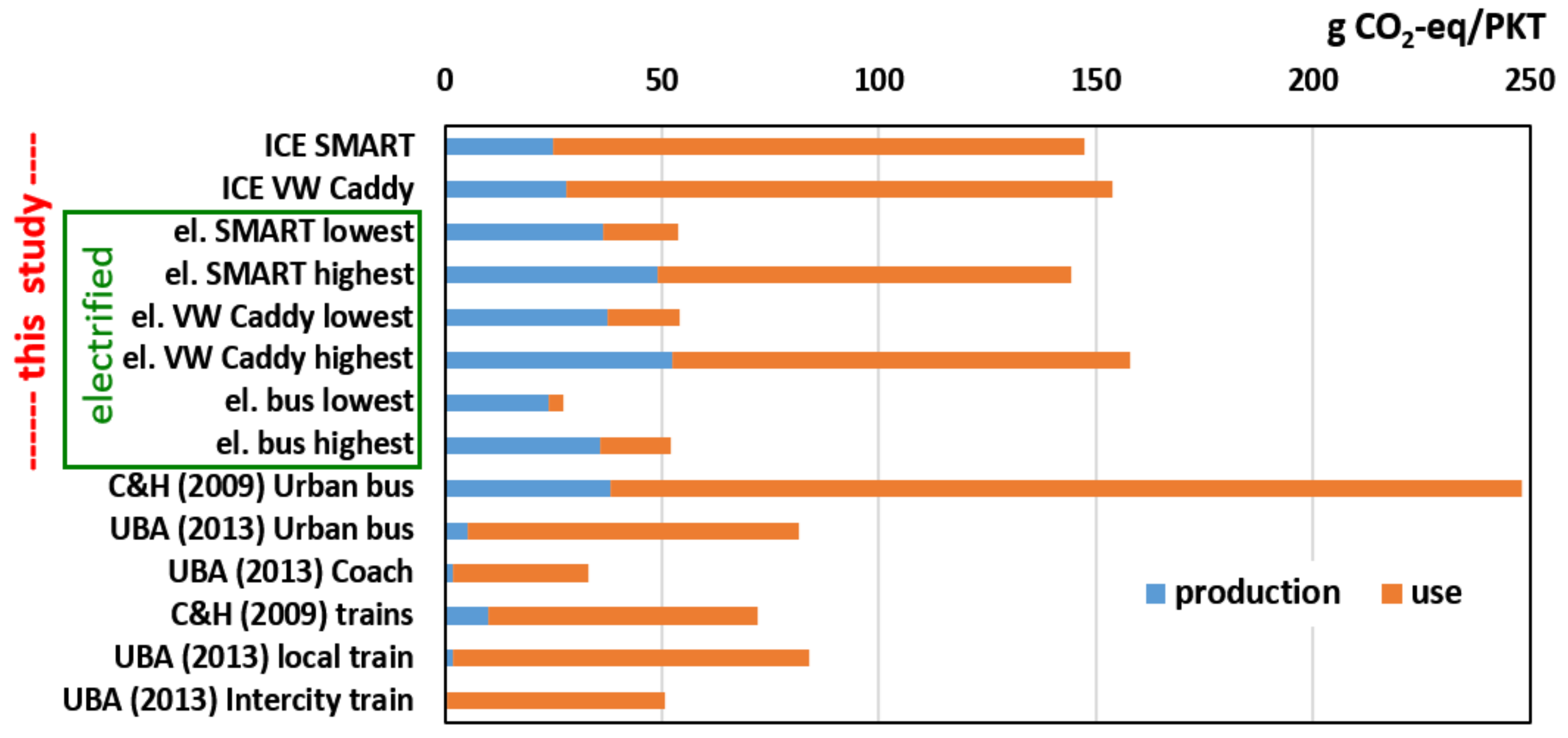

At the end of the study, the researchers made an interesting comparison and determined the effects of the passenger kilometres travelled and compared them with other means of transport. Here, too, various scenarios were calculated for battery production, charging energy and vehicle occupation. “Under optimal conditions,” the researchers write, the climate-friendly effects of electric cars over a lifecycle are “even competitive with public transport such as diesel buses, coaches and trains”. Only one motorised means of transportation could beat electric cars: the electric bus.

mdpi.com (full study, open access)

Reporting by Sebastian Schaal, Germany.

2 Comments