Project eHaul examines robot battery-swapping for trucks

In a three-year project called eHaul, a German consortium of business and science is dedicated to developing an automated battery-swapping station for heavy electric trucks. Among others, the TU Berlin, the Fraunhofer IVI and Bosch are involved in the project.

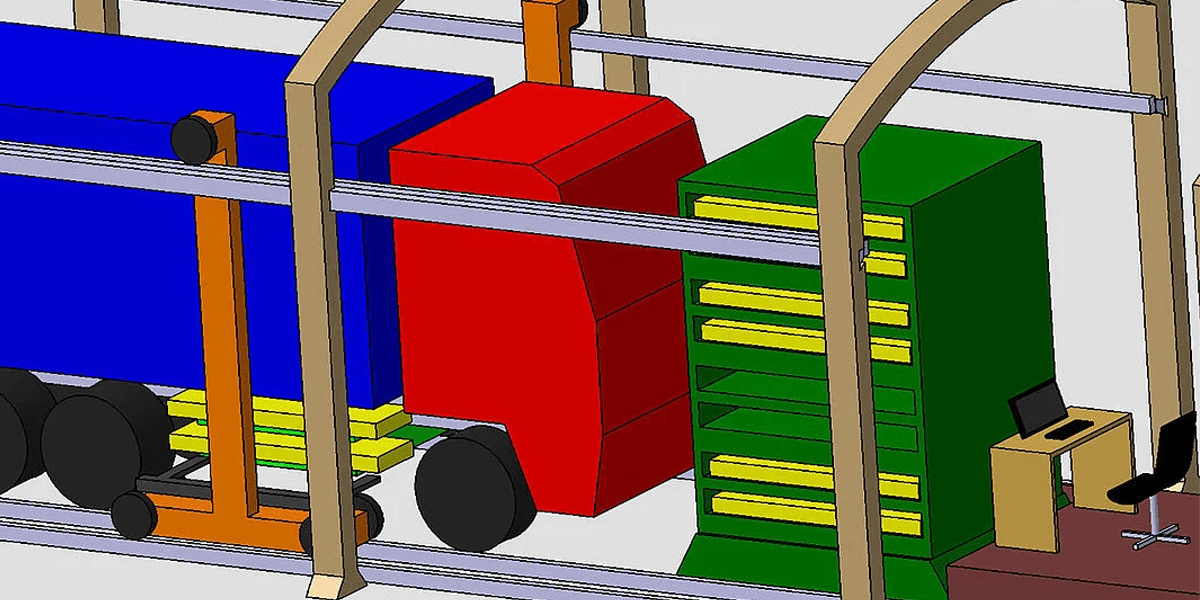

The aim of eHaul is to determine whether large swappable battery for trucks of up to 40 tonnes are a sensible alternative in the transport sector with daily trips of over 300 kilometres. To this end, the initiators want to test their concept of an automated battery-swapping station in practice. The plan is therefore to set up a battery swapping station in the south of Berlin. In parallel, the consortium has just commissioned two electrified trucks, which will then be used by two logistics companies in regular operation.

For more than a year, the truck duo will drive to the swapping station as part of a real delivery operation. In future, a specially developed robot will take over the battery change on-site, which will only take a few minutes. “Both vehicles are fitted with a number of sensors to record data affecting energy consumption during regular operations: the energy consumption of the engine, the load, the weather, the altitude profile of the route, secondary energy consumption such as air conditioning in the driver’s cabin as well as the energy required to maintain cargo hold temperatures,” says Prof. Dr Stefanie Marker, Head of the Department of Driver Behaviour Observation for Energy Optimisation and Accident Prevention at TU Berlin.

Also pursuing a battery swapping system for trucks is the RouteCharge project from the ‘ICT for Electromobility’ technology programme. What differentiates this project from the eHaul project: RouteCharge is about medium-sized trucks in the range of 18 tonnes and medium distances of up to 300 kilometres. In addition, RouteCharge does not necessarily aim for a fully automated battery exchange, but the project participants attach importance to the fact that the batteries remaining in the exchange station deliver primary energy outputs.

For the eHaul project, and investment volume has come together amounting to around 6.5 million euros, which will be covered by a grant from the German Federal Ministry for Economic Affairs and Energy and the partners’ own funds. Over the next few months, the consortium wants to test the technical feasibility and energy consumption data of their approach, as well as its economic viability. The central question is how a system must be designed so that it is economical and offers a real alternative for the logistics industry.

For Professor Marker, it is obvious that electrification of long-distance road freight transport makes sense in principle: “If we were able to begin by electrifying just a few vehicles, the high mileage of these vehicles alone would create a significant absolute impact.” Unfortunately, there are not yet very many electric vehicles in use in the truck segment with up to 40 tonnes, as these are usually only produced on direct demand, she explains. The problem is that most of these large trucks are used for distances that cannot be covered on a battery charge. “Haulage companies also can’t afford to lose hours waiting for a battery to charge.” A network of battery charging stations is therefore a potential solution in their view.

Jens-Olav Jerratsch, team leader under Professor Marker at the TU Berlin and project manager of the joint project, adds that for trucks, battery-electric approaches would compete with hydrogen technology, among other things. “We are examining the option of battery exchange as it is not possible to keep making bigger batteries without negatively affecting other consumption factors. Other options include fast charging, which is already used for passenger cars. For trucks, however, this would require a very high charging capacity – in effect you would need to build a power station next to the charging station – particularly as regular operations would require several trucks to be charged simultaneously.”

Of course, there are also some challenges with a network of battery charging stations. According to Jerratsch, for example, a solution must be found for attaching and contacting the batteries to the truck so that they can be changed quickly and easily. “In the long term, another challenge lies in standardizing exchangeable batteries so as to enable cost-effective, modular battery exchange on a larger scale. However, given the limited number of truck models, this represents less of a problem than for passenger cars.”

With reporting by Cora Werwitzke, France.

0 Comments