Optima showcases machine solution for fuel cells

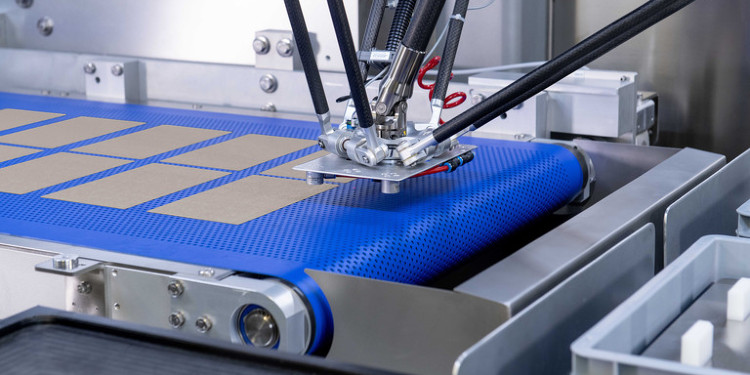

The Optima Group has developed machine solutions to increase the throughput of fuel cells. The process steps required in production, namely coating, cutting, joining the individual layers and stacking, are automated by machine.

According to the family-owned company from Schwäbisch Hall, the system is now available worldwide and is a complete solution for fuel cell production. They offer all process steps involved in the production of MEAs. The stacking of the finished MEAs to form the so-called fuel cell stack is in the final stages of development, says Jürgen Bareiß, head of the Optima Life Science business unit, in which the manufacturing technologies for fuel cells were developed. By the end of the year, this machine solution should also be ready for the market.

The core of the fuel cell is the membrane electrode assembly or MEA for short. Hydrogen and oxygen flow through it and react with each other in the MEA. This is how the electric current required for propulsion is generated electrochemically. An MEA essentially consists of an ion-conducting electrolyte membrane with a catalyst layer on the anode side and a catalyst layer on the cathode side (Catalyst Coated Membrane, CCM) as well as the gas diffusion layers (GDLs). These layers are delivered to the fuel cell or MEA manufacturer in rolls or are produced in-house. There they have to be cut out in the desired size, joined together and fixed.

Optima works together with Coatema Coating Machinery GmbH to ensure the unwinding, coating and cutting of the GDLs as well as the joining of GDL and CCM to the finished MEA as a complete solution. The successful development of the solution is due, among other things, to the synergy effects in the broadly positioned Optima group of companies: “Technologies previously used for manufacturing and packaging processes in the medical technology, consumer goods, and paper hygiene industries have proven to be extremely valuable,” the company says.

Bareiß says: “With our solutions, we strive to become the market leader in the field of complete solutions for fuel cell production and contribute to a more environmentally-friendly mobility.”

Werner Volk, head of new applications/concepts at Optima Life Science, adds that unlike lithium-ion batteries, German companies could well become technological leaders in fuel cell development and production. Against this background, Optima also wants to offer its solution internationally – including the necessary support. Incidentally, the machine system will be presented, among other things, at the f-cell trade fair on 14 and 15 September 2021 at the Haus der Wirtschaft in Stuttgart.

0 Comments