ORNL tackles “key challenge” in solid-state battery production

Scientists at the Oak Ridge National Laboratory say they have developed a scalable, low-cost method to improve the joining of materials in solid-state batteries. The process involves an electrochemical pulse to overcome a “key challenge” of producing solid-state batteries at scale.

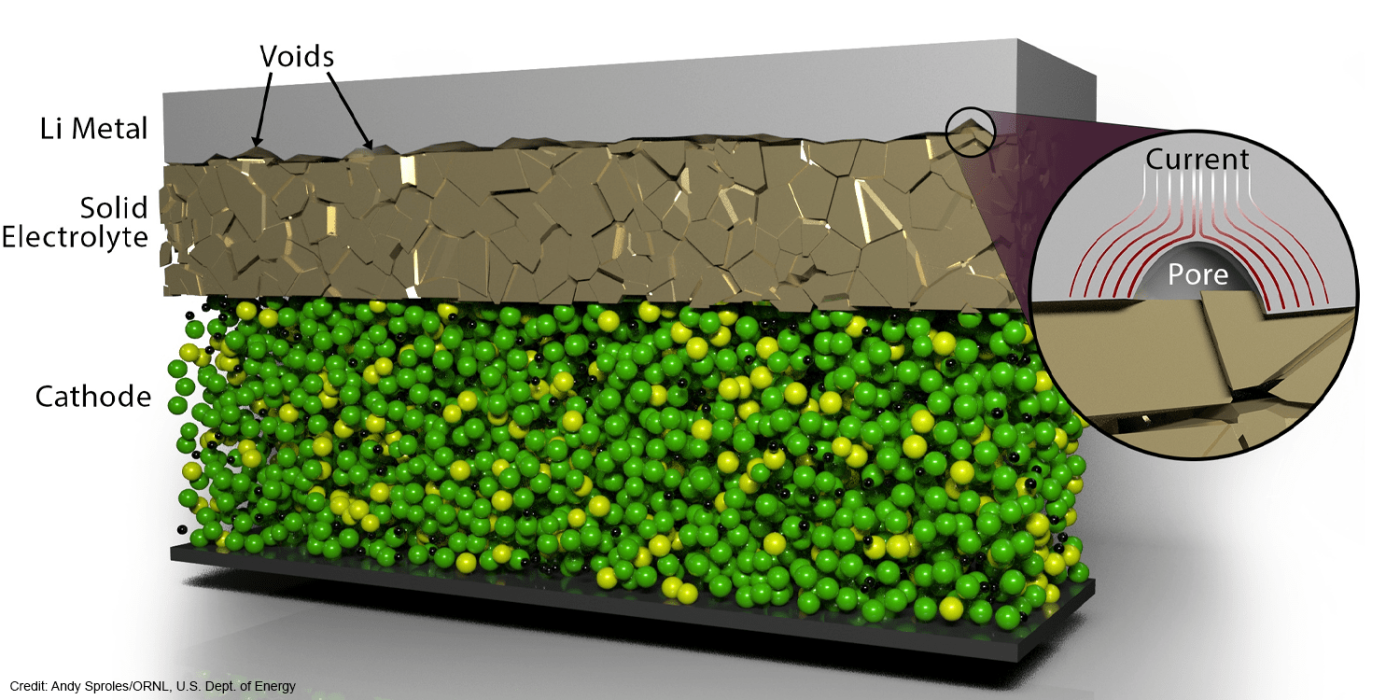

Battery experts know the issue as contact impedance, a term that describes the difficulty of getting materials in solid-state batteries to properly join and remain stable during repeated cycles of charging and discharging. Approaches have focused on primarily applying high pressures; however, this can lead to shorting and would need to be re-applied periodically to extend the battery’s life, implying an expensive aftermarket application.

This is where the ORNL research comes in. The researchers replaced the pressure with an electrochemical pulse. It eliminates the voids that form when joining layers of lithium metal anode material with a solid electrolyte material (in this case, the ceramic garnet-type electrolyte LALZO). Applying short, high-voltage pulses led to increased contact at the interface of the materials while resulting in no detrimental effects, the researchers found.

What is more, the team thinks the approach could be scaled to allow the solid-state battery to be removed and refreshed, bringing it back to nearly the original capacity after extended use.

“This method will enable an all-solid-state architecture without applying an extrinsic force that can damage the cell and is not practical to deploy during the battery’s usage,” said Ilias Belharouak, co-lead on the project and head of the Electrification Section at ORNL. “In the process we’ve developed, the battery can be manufactured as normal, and then a pulse can be applied to rejuvenate and refresh the interface if the battery becomes fatigued.”

The idea for the method came from previous work in which ORNL battery researchers used electrochemical pulses to heal damaging dendrites that can form in solid electrolytes.

The research is ongoing, including experiments with more advanced electrolyte materials, so the statement. ORNL’s multidisciplinary energy storage team is also working to scale up its process to a working-scale solid-state battery system.

0 Comments