EU project BatWoMan to cut battery production costs and waste

The project with the long title: “Carbon Neutral European Battery Cell Production with Sustainable, Innovative Processes and 3D Electrode Design to Manufacture” runs over a period of three years and is financed with 4.85 million euros and thus entirely within the framework of the Horizon Programme of the European Union. In addition to the AIT, the Karlsruhe Institute of Technology (KIT) is also involved in BatWoMan, as are the Fundacion Cidetec, the University of Duisburg-Essen, Sovema Spa, Matthews International GmbH and the Rise Research Institutes of Sweden.

The project focuses on the development and implementation of resource-saving innovations in cell construction. Among other things, this involves process steps such as electrolyte filling or cell conditioning. Specifically, the project participants want to focus on energy-efficient electrodes without volatile organic compounds that are processed with slurries with a high dry matter content. In addition, a concept for reducing the dry space with improved electrolyte filling is to be tested. In terms of cell conditioning, the focus is on wetting, formation and ageing. By means of a platform controlled by artificial intelligence, the project partners want to constantly monitor the sustainability and efficiency of the proposed production steps in the course of the research.

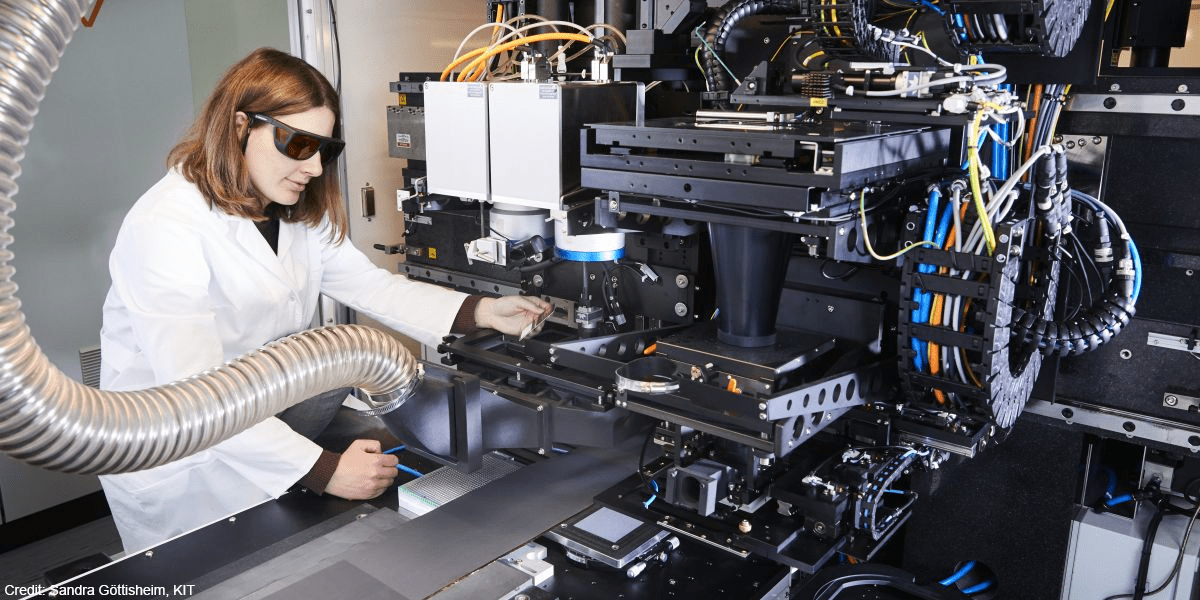

According to its own statement, KIT is contributing, among other things, its expertise in the field of laser-assisted generation of 3D batteries. “We use ultrashort laser pulses to shape battery materials in order to increase electrochemical performance, double battery life and make battery production highly efficient,” says Niclas Straßburger of KIT’s Institute of Applied Materials – Applied Materials Physics.

To this end, the researchers are building a pilot plant in which they can structure battery materials over a large area in a roll-to-roll process by laser and which can be integrated into battery production in the long term.

kit.edu (in German), cordis.europa.eu, batwoman.eu