Nissan streamlines EV and E-Power drive development

Nissan is taking a new approach to powertrain development that integrates zero-emission and hybrid technology. The ‘X in 1’ program sees engineers utilising the same components for both EV and E-Power drives for cost-saving effects.

Nissan estimates the new approach will save up to 30 per cent in development costs in 2026 compared to 2019. The carmaker’s hybrid E-Power system could thus achieve price parity with ICE vehicles within three years, so Nissan.

To understand the approach, it pays to take a look back. Nissan started working on a new hybrid drive in 2010 and finally launched the e-Power system. These kinds of hybrids utilise the petrol engine exclusively to generate electricity so that the motor car always drives electrically – yet, driven by what Nissan called “a power station inside the vehicle” today, which still relies on fossil fuel to generate energy.

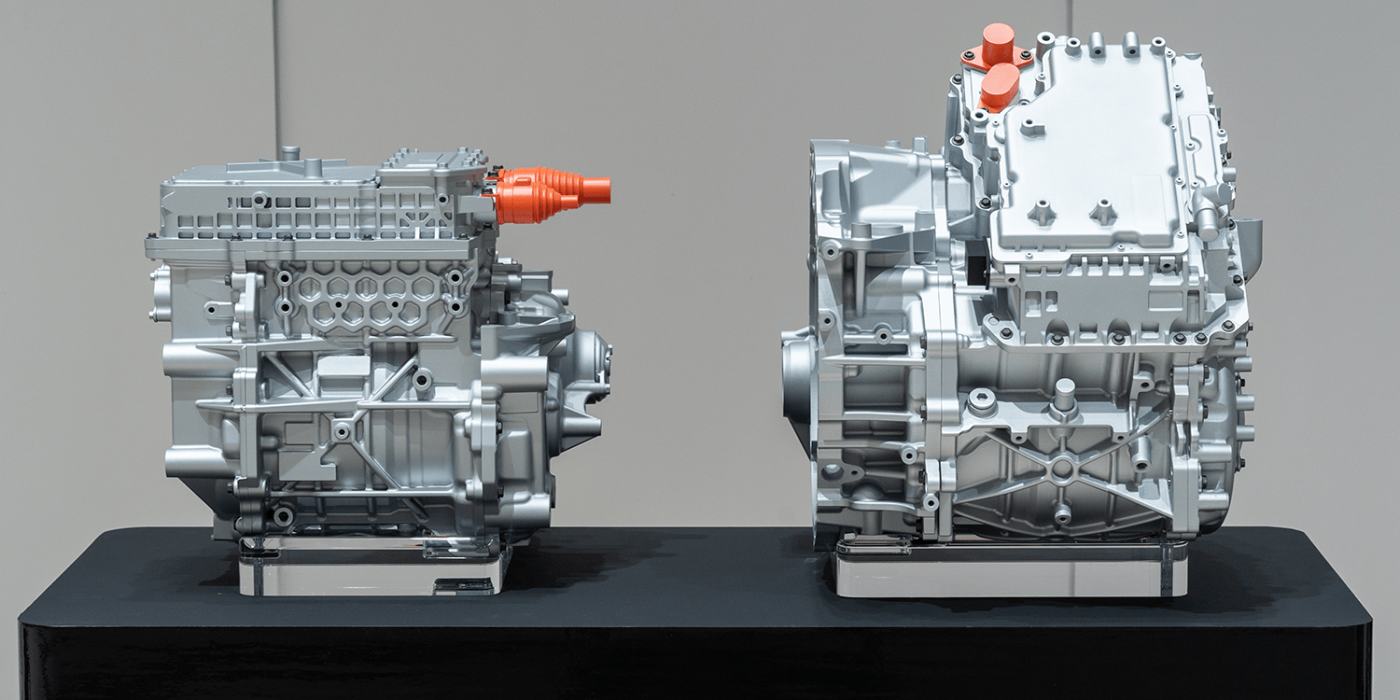

At the same time, the new E-Power drives share components with Nissan’s pure electric drives, namely the traction motor, inverter, and gear. This is also where Nissan’s new ‘X in 1’ labelling comes in.

Their prototype EV drive is called a 3-in-1 powertrain, which modularises the motor, inverter, and reducer (gear). A planned 5-in-1 prototype additionally modularises the generator and “increaser” (aka combustion engine) and designates the new e-Power system.

While this streamlines manufacturing, with Nissan targeting E-Power and EV components coming off the same production lines in the new developments, further cost reductions are being made elsewhere. In its technical presentation, Nissan specifies direct cooling of the inverter. For e-Power drives, this is to help save 20% and 25% of the cost of EV systems. The other 10% cost reduction shall be found in modularisation and decreasing rare earth materials (to 1%), primarily by making magnets more stable (heat resistant).

Nissan also expects the new ‘X-in-1′ drives to be smaller and lighter to achieve a more comfortable driving performance and minimised noise and vibration. As the core components and control technology will be shared, the drives are also expected to offer the “pleasant driving experience” that is “unique to Nissan electric vehicles”. The company had introduced one-pedal driving early on and, being from Japan, emphasises drivers’ comfort in terms of minimising sudden acceleration or hard brakes, e.g. anything that Western drivers may consider dynamic.

Senior Vice President Toshihiro Hirai, who leads powertrain & EV engineering development, said Nissan made “the most of our expertise and know-how from our more-than-a-decade-long development and production of electrified technologies”. The aim was to deliver electrified vehicles “as widely as possible”.

The Nissan Ambition 2030 strategy sees the Japanese corporation targeting a lineup of 27 new electrified models, including 19 EVs, by the fiscal year 2030. In Europe, the corporation will further refrain from investing in Euro 7 technology entirely. It will instead introduce new passenger cars here only with partially or fully electric drives starting this year, as reported.

0 Comments