Customcells test digital twin for battery cell production

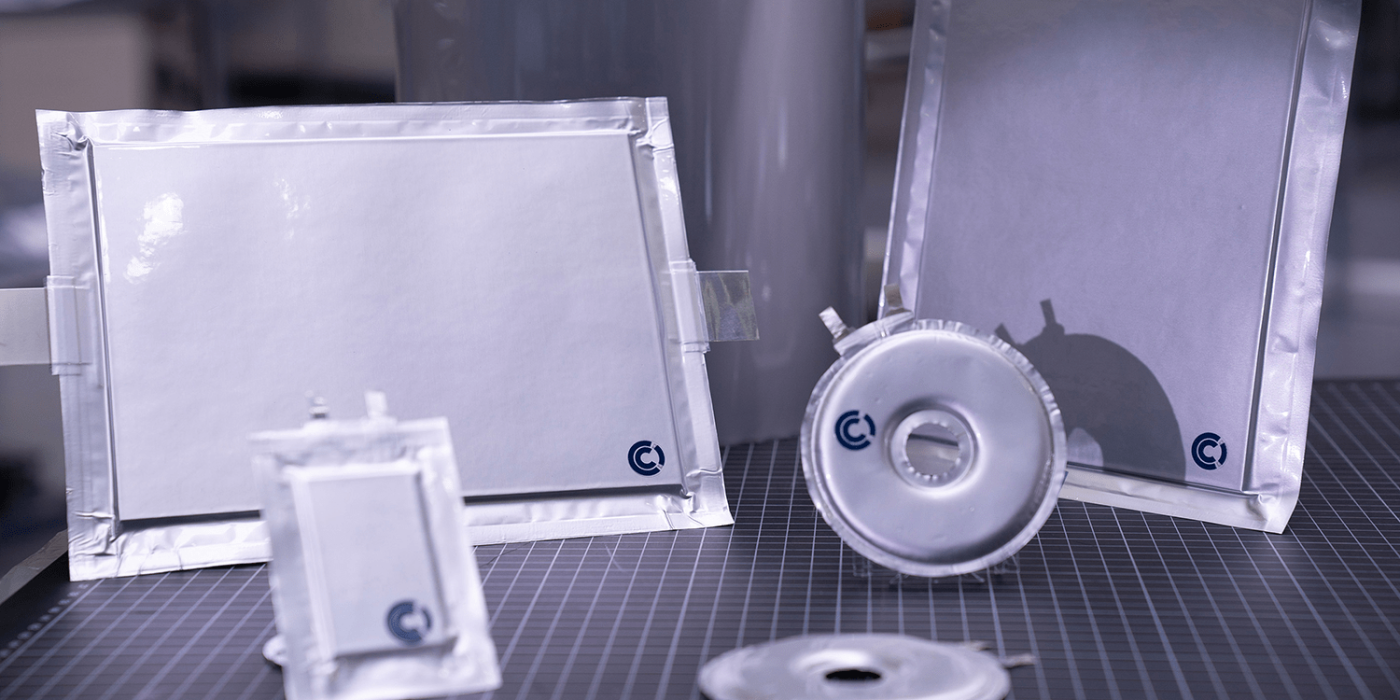

As part of the TwinTRACE joint project, battery company Customcells and partners from industry and research want to digitise battery production. They will set up an intelligent battery factory at Customcells’ site in Tübingen, Germany – complete with a digital twin.

The Fraunhofer Institute for Manufacturing Engineering and Automation IPA and acp systems are partners in the joint project. Together, they will collect all relevant data related to the product and manufacturing process. With TwinTRACE, the project partners say they are bringing the quality and traceability of battery cell production to a world-leading level. The focus is on the production of premium battery cells for applications on the road, on and under water, and in the air.

“The future of battery cell development and production is undoubtedly networked and high-tech,” says Dirk Abendroth, CEO of the Customcells Group. “The digitalisation of the entire process chain contributes to more sustainability and greater efficiency. Such innovations underline our claim of being a leading global brand in the field of premium battery cells.”

A digital twin is a virtual representation of an intended or existing real-world object, system or process. It uses data to represent the latter in real-time, making it possible to simulate, test, monitor or optimise the “real twin” – without having to change the product or process itself.

“The digital twin brings more flexibility and at the same time more quality to processes and opens the field for a whole range of other possibilities,” says Maryam Zehtaban from acp systems AG.

Florian Maier from the Center for Digitized Battery Cell Production (ZDB) at Fraunhofer IPA adds, “Digitisation must not be reduced to collecting and storing data. Value creation through digitisation can only be achieved if the data is also further processed and incorporated into automated decisions – like for process control. This is precisely where the digital twin comes in, offering a technical solution that should be easy to integrate into existing production processes.”

The project is funded by the German Federal Ministry of Economics and Climate Protection (BMWK).

Customcells raised 60 million euros in a Series A financing round just a few months ago. The German battery cell manufacturer intends to use the money to expand its activities in the electrification of air traffic, intensify research and development, and drive forward internationalisation. Customcells’ interest in the aviation battery market has been apparent for some time. For example, it is cooperating with engineering company Manz to establish production capacities for lithium-ion battery cells for customers in the aviation sector. Customcells is also collaborating with the German e-flight cab startup Lilium.

Last year, Abenroth announced that the company is planning at least two more battery cell factories in Germany. The two factories expand the company’s production capacities, which have so far been limited to the Itzehoe and Tübingen sites. In addition, a battery production plant is already under construction in Reutlingen-Nord/Kirchentellinsfurt under the direction of the battery joint venture Cellforce Group with Porsche. The foundation stone for the latter plant was laid in October. At the same time, Cellforce announced plans to increase production capacity there tenfold to over 1 GWh.

0 Comments