Where Europe can lead on Critical Raw Materials

With the EU Commission having drafted the Critical Raw Materials Act (CRMA), we talked to Vulcan Energy, Skeleton Technologies and volytica diagnostics, who all have new approaches to the supply and use of battery raw materials.

We also gathered statements from EU Commissioners Thierry Breton and Valdis Dombrovskis and the German Chamber of Industry and Commerce (IHK). What emerged gives a glimpse into where Europe is headed and where it may take new approaches to secure the battery supply chain.

* * *

The general objective of the recently published CRMA is to address the lack of secure and sustainable access to critical raw materials for the EU. For Europe to engage in the vehicle and energy industries, it must ensure an adequate supply of materials to make EV batteries and batteries for stationary energy storage.

The statements and responses we gathered reflected a generally positive atmosphere towards Europe’s intended approach to critical raw materials. As Arnaud Castaignet from Skeleton Technologies put it, “It’s a good roadmap,” although there are areas that need more focus. He said, among other things, more attention is needed for innovation in materials to find substitutes for finite materials.

As we learned from Claudius Jehle, CEO of volytica diagnostics, adequate guidelines for measuring and monitoring batteries are required to enable their effective use and second life before recycling. Other feedback from Vulcan Energy Resources and the German IHK addresses the effectiveness of bureaucracy and financing so that nobody gets caught up in red tape that inhibits business participation in these emerging and vital industries.

Where is the EU at with critical raw materials internationally?

EU Commissioner and Executive Vice-President Valdis Dombrovskis points out in his statement on the CRMA: “We are not a resource-rich continent. Our domestic supply will provide only a fraction of the critical raw materials we need.” He extrapolates, “As you know, we are working on a targeted agreement with the United States aimed at helping to build a green transatlantic marketplace. Specifically, we want to achieve FTA-equivalent treatment for raw material supplies in the context of the Inflation Reduction Act.”

Thierry Breton, EU Commissioner for Internal Markets, notes: “We are experiencing a global race for the supply and recycling of critical raw materials.”

Taking a broad look at international economies and markets, although Europe is taking second place to China regarding the amount of battery materials being sourced and processed – Europe also has a better reputation for transparency in sustainability with environmental and labour protection mechanisms.

Exactly these issues of sustainability, social and environmental impact are considered most important for the world’s strongest economies in the APAC region, for example, which also represents the world’s fastest-growing consumer markets, among which electric vehicles are some of the only products and services seeing an increase in use in a generally dampened global economic outlook.

Locally sourced raw materials

Starting off with mining, the CRMA has already identified the importance of resilience at the beginning of the chain, where the materials come from in the first place, so we asked Vulcan Energy Resources for a response to the proposed CRMA. Vulcan Energy is currently filtering lithium from geothermal brine in the Upper Rhine region in Germany, among other projects. The company specialises in the extraction of lithium in Europe and has supply agreements with Stellantis, Renault, Umicore, and Volkswagen.

Vincent Ledoux Pedailles, the Chief Commercial Officer at Vulcan Energy Resources said: “The CRMA proposal is going in the right direction to support the development of lithium projects in Europe and in combination with the NZIA, which also supports geothermal projects, it is another good news for geothermal lithium projects like Vulcan.”

“The proposal’s main axis seems to be focusing on permitting and on how to accelerate the process across Europe by mostly selecting so called ‘Critical Projects’ and allocating one authority per country to drive the permitting process in a centralised, and therefore faster manner, i.e., under two years for integrated mining projects,” he summarised. A development that is also mentioned positively in the statement by the German IHK, among others.

“Financing support is also addressed in the proposal but still vague,” Ledoux Pedailles continued, though acknowledging that a budget matching or above the US American Inflation Reduction Act is to be expected. He explained that “The main remaining unknown with the proposal is timing and when projects in Europe will actually benefit from this proposal.”

On the financing side, as the Chief Commercial Officer at Vulcan anticipates, Europe is getting ready to gear up on the local mining front since both Commissioner Thierry and Dombrovskis identified financing and regulation to be a key area of focus.

To take a look at the international situation, while Europe’s immediate competitors and collaborators USA and China, are looking at CRMs from a strategic point of view, both have failed to fully address or harness environmental and labour regulations in the way that Europe has – especially with projects like the Battery Passport that enables source material transparency along the whole lifecycle of a battery. So, while Europe does have a credible advantage on this front, it now has the challenge of identifying the key issues in the full circularity of battery materials.

Renewable substitutes for critical raw materials

A good example of one of the most vital and difficult raw materials to get hold of is graphite, one of the 16 raw materials listed as being of strategic importance in the proposed CRMA. Graphite requires the largest production increase of all the battery minerals, and almost all of it currently comes from China. Graphite is also a key component in hydrogen fuel cells. In 2021, there were approximately 20 junior public graphite mining companies with advanced-stage, feasibility study-level projects. Fourteen are in Africa with varying degrees of security/stability risk.

It doesn’t take long to realise the importance of this critical raw material for the transport industry. Graphite is also generally sourced to make the wonder material called graphene. For electric vehicles, graphene enhances mechanical properties while adding useful life and lightness.

Skeleton Technologies uses a special kind of graphene for its ultracapacitors and special batteries. When we asked Arnaud Castaignet, Vice President, Public Relations & Government Affairs, Skeleton Technologies, which strategic raw materials his company requires for its batteries and supercapacitors and how much graphite it needs, the simple answer to both questions was: “Actually, none.”

This is because Skeleton Technologies has found a way to produce graphene with renewable materials. The company’s supercapacitors, SuperBatteries, and solid-state batteries are all made with their proprietary ‘Curved Graphene’, which is renewable and all sourced from within Europe, meaning that European companies do not need to go to China or the United States for battery and ultracapacitor production.

Castaignet commented that although the CRMA rightly identifies raw materials that are critical, there is nothing in the CRMA in terms of support for innovation in materials. “There are many cases – not only in our case – where we saw that you can also develop substitutions for such materials. This is our case with curved graphene.”

He explains that it’s not just about substituting materials, it’s also about developing more efficient uses of materials. This is also a big focus at Skeleton. The company’s graphene-based ultracapacitors are said double the battery life when combined with Li-ion batteries.

There are examples of this elsewhere, too: “Which has been the case, for instance, in solar cells with a reduction the use of silver and silicon,” Castiagnet points out. To the European Commission on the CRMA, “We would suggest that they also explore either a better, more efficient use of such materials, or the development of substitutions that would allow Europe to do without many of those materials.”

Skeleton Technologies has shown just what can be managed with devotion to sustainable principles. “We even sell the byproduct of the processing of curved graphene. We sell it to companies in the solar industry.”

This is where the European Commission can provide some guidance in the future. “We are in favour of having some really strong requirements for the entire value chain in terms of recycling these materials – making sure that they don’t generate much waste,” Castiagnet states.

This approach is indeed strongly presented in the EU CRMA, about which he notes, “We see very positively that there’s strong emphasis on the recycling part (in the CRMA proposal) and on having it as circular as possible, because this is indeed what we see as what should be the focus.”

What does sustainability and circularity mean for battery raw materials?

Sustainability means you can sustain something that can theoretically go on forever, which means all materials are renewable and, therefore, in endless supply. In the case of EV and stationary energy storage batteries, this means; when raw materials need to be mined, the most must be made of them before they get recycled as fully as possible so that these raw materials can stay in an endless cycle of use and reuse (second life), no geopolitical games required.

This is where Claudius Jehle CEO of volytica diagnostics had some strong opinions about using critical raw materials. He advocates for batteries being constantly monitored with mandatory testing to signal the end of their use life for each phase of that life, rather than an arbitrarily set period of time after which batteries are, in the worst-case scenario, thrown out, and in the best case scenario are used to the maximum potential in more than one application before finally being recycled.

“I would advocate for batteries used in their designated purpose for as long as they serve this purpose, but this is not the fact at the very moment; they’re being replaced typically at the end of the warranty.”

He gives an example of a public transport operator in northern Europe who was not able to determine whether the batteries for their electric buses were still good or not: “They had to replace the batteries worth 14 million euros for, I think, 136 electric buses.”

Jehle explained that because people don’t know what’s going on and how good their batteries are at the end of the manufacturer’s warranty period, they would rather throw them away and buy new ones than check them to find out how to prolong their first life and be viable for a second. This was Jehle’s motivation to found volytica diagnostics: to be able to properly monitor batteries so that they can be used for an optimal amount of time in each phase of its life. We most recently reported volytica began working with Mahle on battery diagnostic tools for electric cars.

“If there are guidelines for proper monitoring and proper analysis of these things, then the owner has the proof at hand to sell this thing in a second life for a second purpose. Without these indicators, no one would assume the risk of buying an unknown battery. If you don’t know what has happened to it before, then you can’t repurpose it, bringing it to a second life and giving it another warranty, which is what inhibits the second-life market.”

This is a factor not even mentioned in Biden’s Inflation Reduction Act. And in Europe, it was only mentioned in the CRMA in terms of a vague reference to circularity. Europe has already been selling electric vehicles for long enough for the first electric vehicle batteries to be ready for second-life purposes. If these systems are not immediately put in place, battery raw materials will be wasted as we speak.

In China, the amount of batteries hitting second-life markets is enormous, and the further lives of batteries beyond their initial purpose is now unfolding into several profitable industries.

The process of life between the initial purpose of the battery and its eventual recycling is regulated by the so-called cadence or ladder method of prioritizing the most critical uses for second-life applications. Translated to European or North American contexts, this would mean stipulating that, for example, batteries from large electric cars must be used in second-life applications in stationary storage, for buffering the grid in areas prone to blackouts, for example, or those batteries from large high-performance vehicles then be prioritised for use for smaller, slower vehicles in dense inner-city areas, for example.

This second life radically reduces the overall amount of raw materials needed by any given region as well as dramatically reducing the amount of energy required for manufacturing at each step of this life.

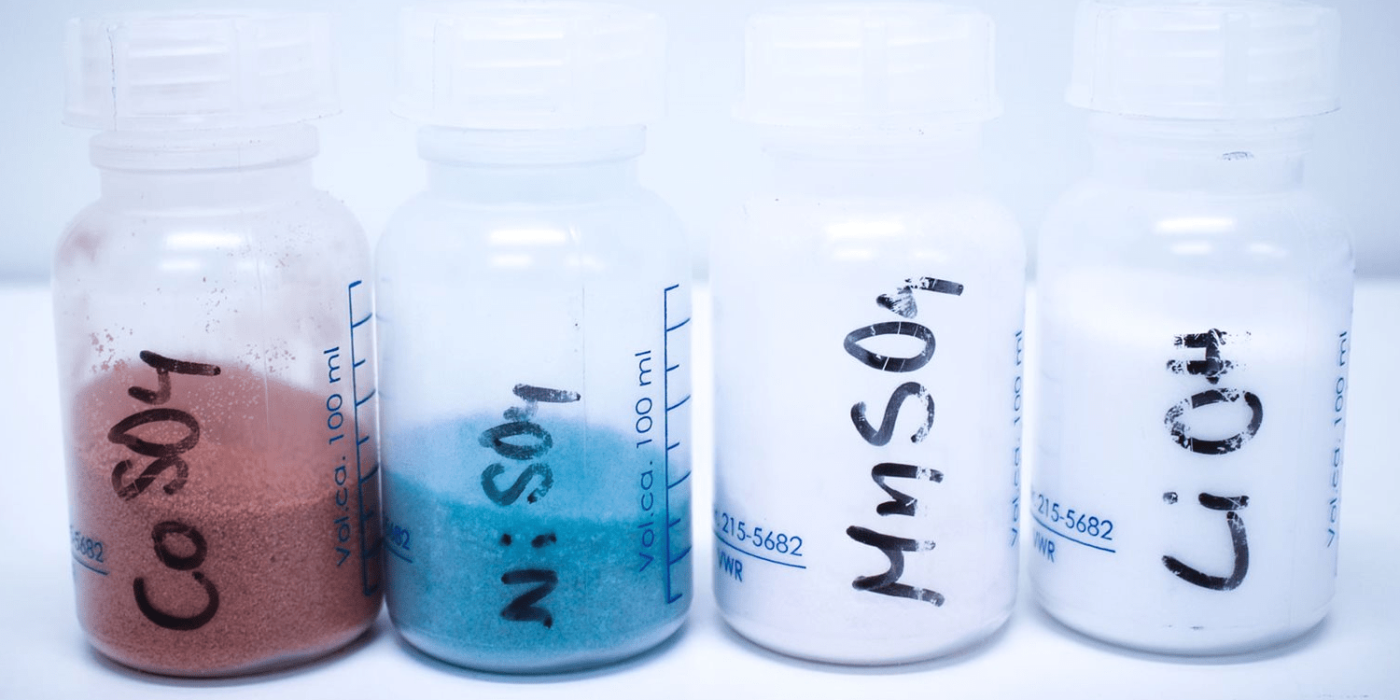

When hearing that China is trying to improve its recycling rates which are currently far below what is targeted, Jehle brought up another vital point when it comes to critical raw materials. He gives the analogy that lithium batteries are not just one species but like a whole zoo. “There are dozens of types of animals in the Lithium Ion Zoo: there is Nickel-Manganese-Cobalt-based Lithium Ion technology, or there is Lithium Iron Phosphate -based technology (LFP). And in China, more than 90% of the batteries used there is LFP technology, by the way, not too bad of a technology but this is very difficult to recycle.”

Commissioner Dombrovskis’ reference in his statement perhaps alludes to the kinds of European industries that will hopefully benefit in the unfolding industries of the near future: “The level of integration for trade in both goods and services has doubled in the last 30 years. However, integration in services – which account for around 70% of the EU’s GDP – remains well below that for goods. These are some of the issues that we want to tackle.”

International situation and European advantage

Sustainability is a selling point, not only for publicity and reputation but also for very fundamental practical, economic and business reasons. Countries, companies and continents that make the most out of their raw materials need less raw materials to start with, get more use out of the materials they have and become self-contained without geopolitical stressors once those raw materials are in the loop.

The question will be whether Europe’s international credibility for environmental and social standards can be furthered and maintained. The trick will be establishing regulations that guide and support those participating in the flow of battery raw materials without drowning them in prohibitive regulations.

The German Chamber for Industry and Commerce noted, among other comments and praise for the CRMA: “Government requirements to diversify the supply of raw materials to companies (…) overshoot the mark. Companies are already adjusting their supply chains on the basis of their risk assessments for business reasons anyway. At the same time, the expansion of government monitoring threatens additional reporting obligations, audits or other new bureaucratic burdens for companies, and this, despite the reduction in reporting obligations announced by Ms von der Leyen.”

But the German Chamber of Industry also admitted the CRMA provides a good impetus. Generally, industry feedback appears to be that it is broadly welcomed and provides a good roadmap. It, therefore, seems appropriate to let the EU Commissioners have the last words since they already seem to foresee the next steps:

Commissioner Dombrovskis notes, “However, we need smarter regulation as well. That way, we can boost growth and maintain a globally attractive business environment – for example, looking at how we can reduce administrative burden and reporting requirements.”

Commissioner Thierry states: “Targeted amendments and harmonization to existing legislation, notably on waste, would promote quality recycling of strategic raw materials and an efficient market for secondary raw materials, in line with our circular economy objectives.”

The European Critical Raw Materials Act has been published for feedback until the middle of next month, the 15 of May 2023.

0 Comments