i-skaB: Research project on automated fuel cell production

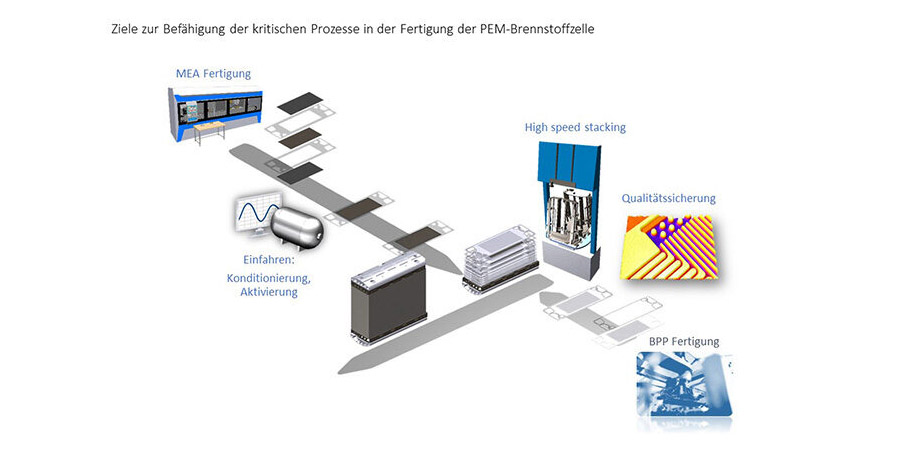

The joint project i-skaB wants to further develop fuel cell production. The goal is to fully automate what is currently primarily a manual production process.

According to a statement by Fraunhofer IPM, it should increase annual production by a factor of 20: from up to 25,000 to over 500,000 fuel cells per year in the medium term on one production line. Currently, the degree of automation of fuel cell production lines and the production of central components such as bipolar plates (BPP) and membrane electrode assemblies (MEA) is “very low”. Due to the low cycle times, only a few fuel cell stacks are built per day.

With the combined know-how of the five industrial companies and two research institutes, the i-skaB consortium partners want to scale fuel cell production.

The project will run for three years. All key production process technologies will be optimised, tested and validated. Another critical aspect of the project is “the establishment of a fast optical quality assurance based on innovative computer vision approaches and 3D measurement techniques such as digital holography”, according to Fraunhofer IPM.

The federally funded project i-skaB (innovative, scalable fuel cell production) started at the beginning of this year and will run until the end of 2025. Project partners are ThyssenKrupp Automation Engineering (consortium leader), BMW, Siemens, Laufenberg GmbH, SK LASER GmbH, the Center for Fuel Cell Technology (ZBT) and Fraunhofer IPM.

The German Federal Ministry of Transport funds the project with just over €3.3 million. The largest single sum of just over €1 million goes to the ZBT, and over €700,000 to each ThyssenKrupp Automation Engineering and the Fraunhofer IPM. The funding amounts for BMW and Siemens are lower; the exact amounts can be found in the NOW announcement linked below.

idw-online.de (in German), now-gmbh.de

0 Comments