Nio buys drive production plant from Comau

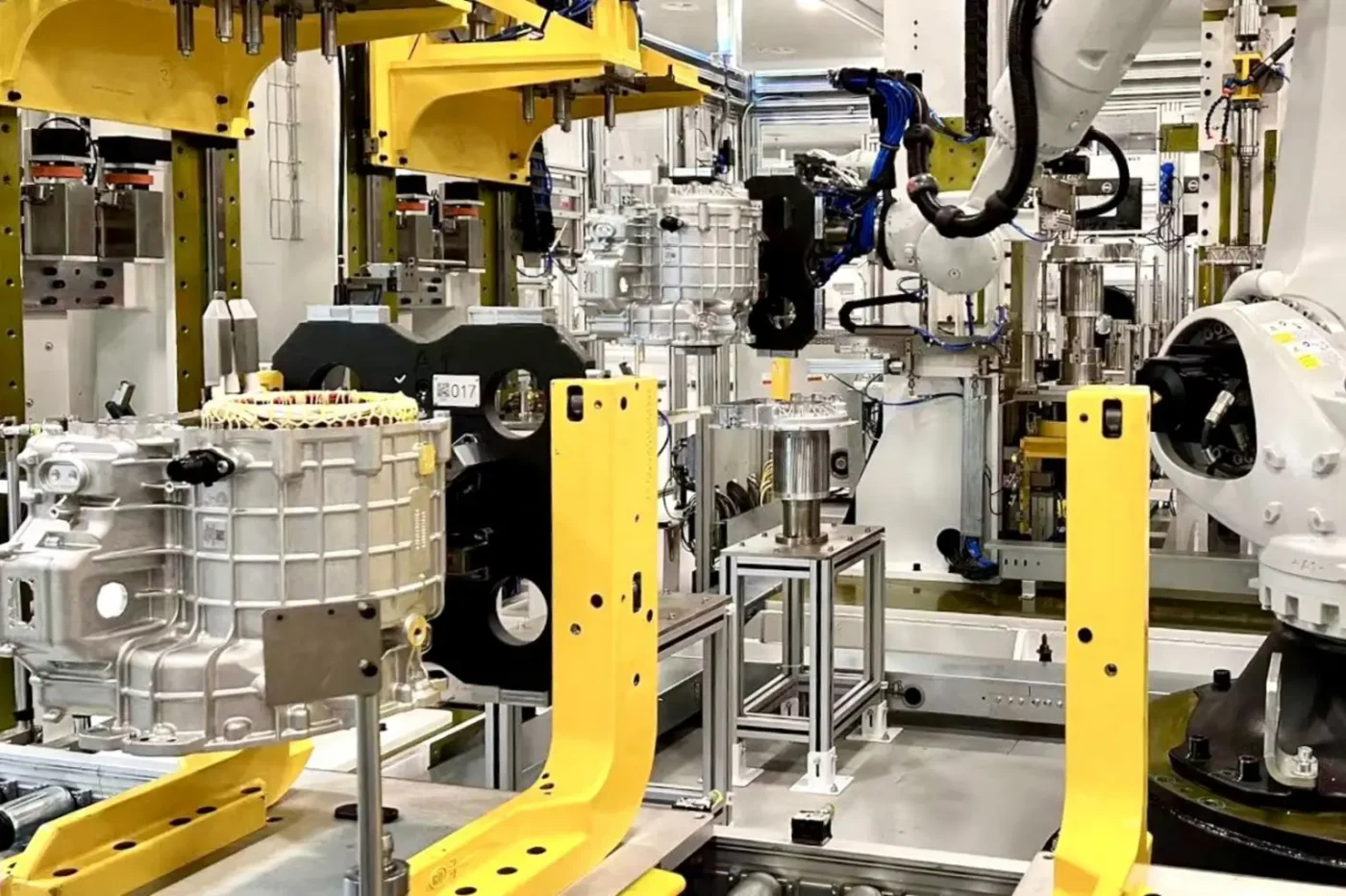

Comau’s solution includes primary lines such as electric motor assembly lines, gearbox manufacturing and inverter assembly lines, as well as end-of-line (EOL) testing processes. The project also ensures co-line production for Nio’s third generation asynchronous motors (ASM) and permanent magnet synchronous motors (PSM).

It is designed to support a large annual production capacity of one million units to be used in Nio’s electric sedans, coupes and SUVs, as well as selected models of its ALPS sub-brand.

According to Comau, the solution developed for Nio offers “optimal flexibility and scalability”. This is to allow the customer to adapt its production environment to the various process parameters. This flexibility also includes the joint production of PSM and ASM. For this purpose, a new adapter with a so-called zero-point positioning device was developed together with Nio’s E-Drive team. “This innovative accessory effectively unifies design, process, and control standards, allowing different assembly requirements to be met while maintaining maximum flexibility,” Comau wrote.

“When it comes to implementing cutting-edge technological solutions, experience and know-how play a decisive role in success. We have been deeply impressed by Comau’s extensive expertise in electric drive systems assembly throughout our partnership,” Alan Zeng, senior vice president of NIO and CEO of XPT, is quoted as saying in the Comau release. “The innovative solution has reliably supported the project, helping us overcome various challenges and achieve our desired results.”

0 Comments