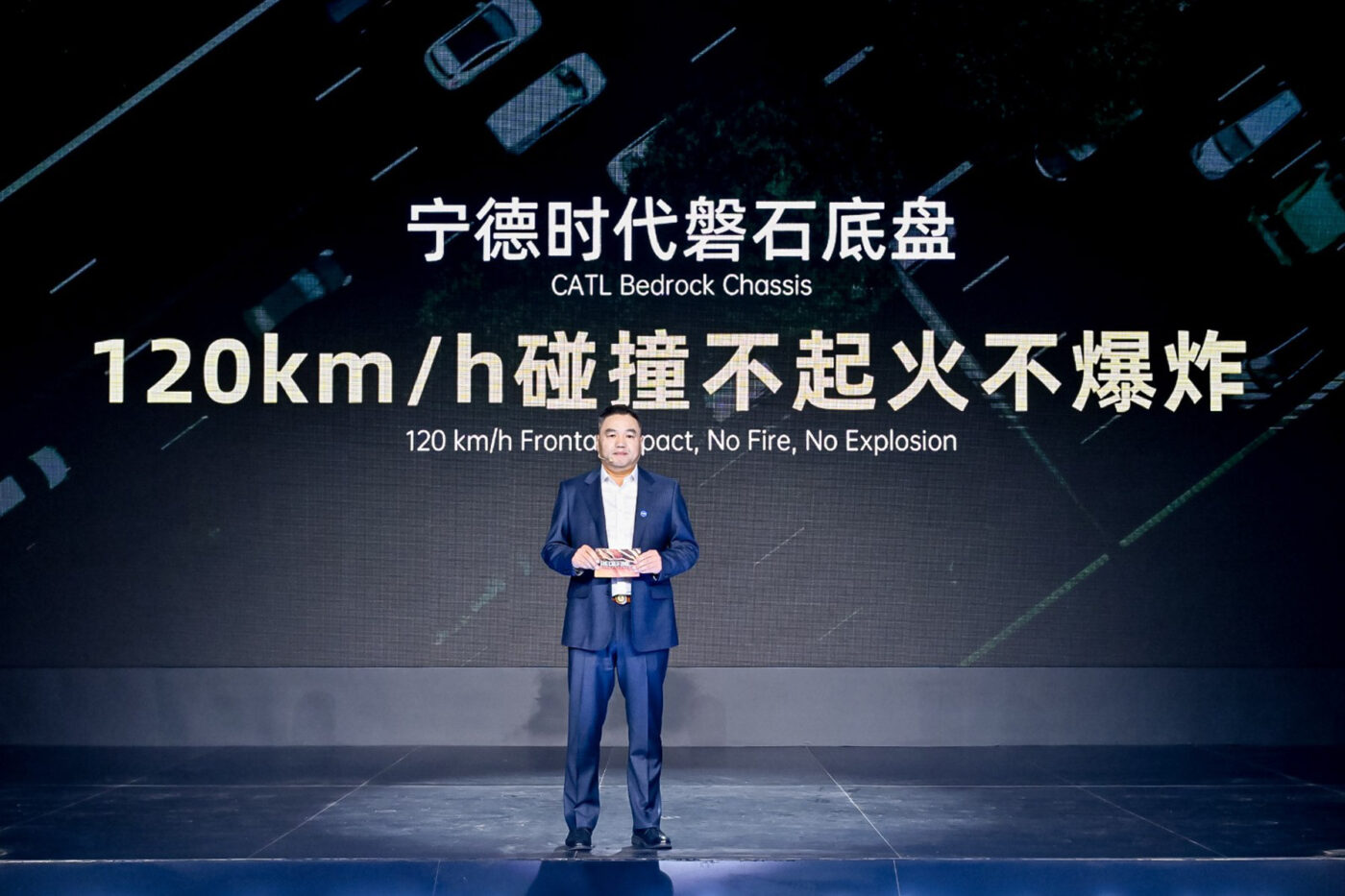

CATL presents electric car chassis with a focus on safety

According to CATL, the Bedrock chassis can absorb 85 per cent of the vehicle’s collision energy (compared to around 60 per cent absorbed by conventional chassis). The chassis is designed to withstand an impact at 120 kph without catching fire or exploding.

The Bedrock chassis is based on CATL’s well-known cell-to-chassis technology, meaning cells are integrated directly into the chassis, making the battery a load-bearing part of the structure. CATL already offers an EV platform with cell-to-chassis technology in the form of the CIIC (‘CATL Integrated Intelligent Chassis’). In the press release, the battery manufacturer does not mention any technical relationship between the CIIC and the new Bedrock chassis. However, according to the CnEVPost, the Bedrock chassis is the flagship version of the latter.

CATL does not go into great detail about the innovations of the Bedrock chassis, but uses a few comparisons to describe the new features. The “revolutionary three-dimensional biomimetic” (i.e. imitating biological processes or structures) structure was inspired by the shell of a tortoise. In other aspects, CATL refers to military models: The impact structure is said to be designed in “aircraft carrier-grade,” the hot-formed steel in “submarine-grade” has a strength of 2,000 MPa, and the aluminium alloys used, with a strength of 600 MPa, would otherwise be used in the aerospace industry. These materials and structures are intended to increase the rigidity of the chassis and make it “virtually impervious.”

There is also a new, “ultra-safe” construction method for the installed cells. A “high-ductility energy-absorbing insulation film” is supposed to increase safety. In the event of an accident, the manufacturer promises that the high-voltage circuit will be switched off within 0.01 seconds of the impact. The remaining energy in the high-voltage system should be discharged in 0.2 seconds. According to CATL, the cells should also have passed a series of other demanding tests, such as a 90-degree bending test or a sawing test. However, these procedures are not specified in more detail.

CATL claims that these innovations have “elevated the safety standards of battery cells to new heights.” The battery manufacturer calculates that the impact energy of a frontal crash in the standard C-NCAP (China New Car Assessment Program) at 56 kph corresponds to a fall from a twelve-metre high building. The frontal impact at 120 kph, which the CATL chassis is said to have survived, corresponds to a fall from a 56-metre-high building.

CATL also presented a launch customer for the Bedrock chassis at the event, which took place in December 2024: Avatr is to be the first manufacturer to use the new chassis. This is not surprising, as CATL holds a minority stake in the car manufacturer, the largest shareholder being Changan. However, it is not yet known which model will use the Bedrock chassis and when it will launch. Neta was still the launch customer for the CIIC.

0 Comments