Solid-state battery from Farasis undergoes practical testing

To clarify: Farasis refers to the cells produced since 2022 with a semi-solid electrolyte, specifically a ‘gel-first technology,’ as the first generation. These cells are used by Dongfeng, GAC, Geely and “many foreign customers.” The second-generation cells are also already in use, with Farasis introducing a “new oxide/polymer solid electrolyte coating and densification technology.” These cells have an energy density of 330 Wh/kg, a charging rate of 3C and a shelf life of over 4,000 cycles.

The new third-generation cells have several innovations, including a solid electrolyte with high conductivity, as Farasis writes in the update. Other innovations include a surface hardening technology for the anode and a cathode with an “ultra-high” nickel content. However, the exact nickel content is not specified. It should also be possible to suppress the expansion of the anode, “which significantly reduces the amount of electrolyte and improves thermal stability.” The energy density should reach up to 400 Wh/kg. It is currently undergoing automotive-grade certification and development, says Farasis.

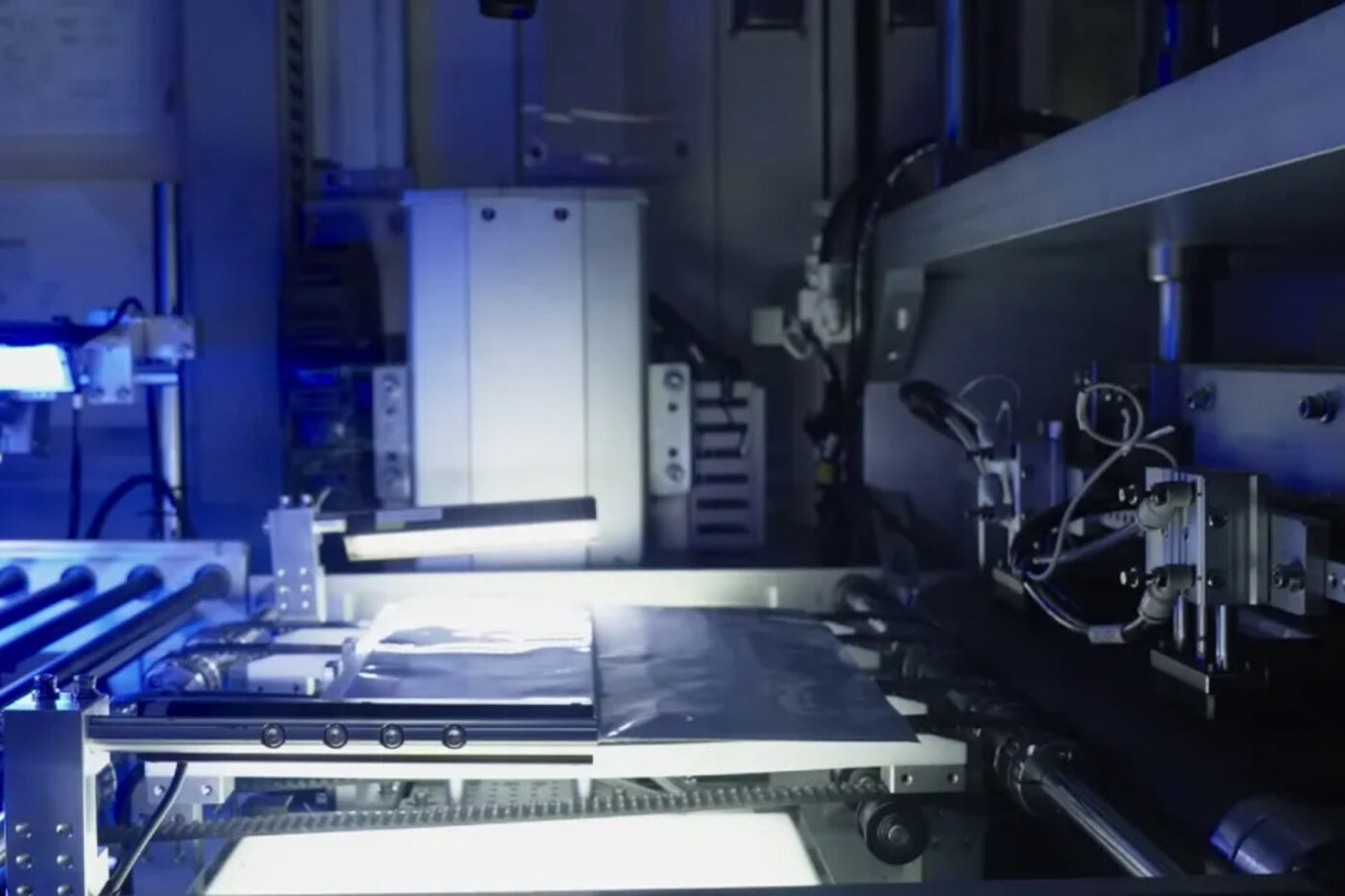

The cell is apparently based on a sulphide system – and thus does not work on an oxide basis like most conventional cells. The anode is based on lithium metal with a high silicon content. Until now, it has been the case that the higher the silicon content, the higher the energy density, but also the expansion/contraction of the anode during charging and discharging, which is at the expense of durability – but Farasis wants to be able to “suppress” this, as mentioned. The company also writes that these cells can be manufactured on conventional production lines.

In addition to energy density, safety is also said to have been improved – after all, the flammable liquid electrolyte is no longer used in the third generation. The cells are said to have passed nail penetration tests, shear tests and hot box tests, according to Farasis. In addition, the cell “can switch itself off at battery level in the event of thermal runaway.”

In the update, the manufacturer also gives an outlook on the next generation: with an “oxide/polymer composite system” instead of the sulphide base, energy densities of up to 500 Wh/kg should be possible – again with lithium metal anodes and cathodes with a high nickel content. However, these composite materials are still being developed, and there is no time frame yet.

cnevpost.com, farasis.com (in Chinese)

1 Comment