Porsche presents alternating current battery concept

Traditionally, a drive system consists of a high-voltage battery coupled with a battery management system, power electronics for controlling the electric motor, and an onboard charger for charging with AC power. In this system, the power electronics convert the DC voltage of the high-voltage battery into the sinusoidal three-phase AC voltage for the traction motor using a pulse inverter.

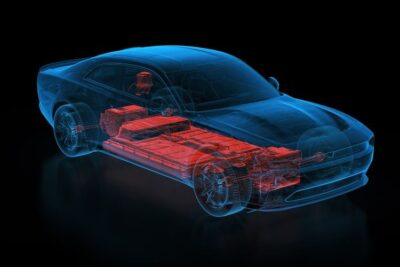

The German automobile giant Porsche has now decided to improve the design for future vehicles, as this “structure has proved its usefulness in current vehicles.” To do so, the developers at Porsche Engineering divided the high-voltage battery of the electric drive into 18 individual battery modules, distributed over three phases.

According to Porsche, these can be controlled individually via power semiconductor switches. “The flexible interconnection of the individual battery modules into a Modular Multilevel Series Parallel Converter (MMSPC) as a distributed real-time system enables dynamic modeling of the voltage curve, so that the sinusoidal three-phase AC voltage for the motor can be generated directly from the DC voltage from the battery modules,” the company wrote in an accompanying press release.

Porsche further explains that the new battery concept is controlled by a standardised control unit concept “with a particularly powerful and real-time capable computer platform.” According to the manufacturer, the system was “developed as part of a feasibility study, trialled on a test bench and demonstrated in a vehicle.”

This individual control is also lauded as a safety feature, for example, should an EV get into an accident, “Then the MMSPC is switched off and the system effectively reverts back to its individual modules, meaning that only the module voltage can still be measured,” explains Thomas Wenka, Specialist Project Manager at Porsche Engineering.

Wenka further explained: “The trend in the automotive industry is toward highly integrated components. This opens up new possibilities in terms of housing size, weight and cost reduction, reliability and efficiency.”

Next to the AC battery concept, the control unit was also redesigned by Porsche Engineering. This control unit stands out with a particularly powerful real-time, uniform, and highly integrated computing platform, which allows for individual battery functions, such as motor and battery management, to run parallel.

“The processing unit represents a heterogeneous multiprocessor platform and runs as a single system-on-chip. It combines a field-programmable gate array (FPGA)—an integrated circuit with programmable hardware— for data control and monitoring with regard to the real-time capability of the system, and a powerful multicore processor for processing large amounts of data in a single component,” explained Daniel Simon, Specialist Project Manager at Porsche Engineering. He further explains: “The FPGA can take over complex calculations to relieve the processor and supplement missing peripherals, which are significant advantages in terms of scalability and flexibility compared to the usual pure microcontroller solutions. And by selecting the derivative within the system-on-chip family, the performance can be scaled from basic ECU requirements—such as I/O-driven, communication gateway or power electronics—to complex ADAS systems with additional GPU and video codec requirements.”

In the past years, Porsche Engineering also revealed progress in battery research, as the company had established a digital twin system for drive development in 2023, which was then further refined to help develop battery systems in 2024.

0 Comments