Researchers want to develop new silicon-tin sulfide composite anode for batteries

AIT states that the project’s goal is, among other things, to reduce the need for raw materials and increase battery performance. The first aspect can already be achieved by using recycled materials, in this case from disused solar modules.

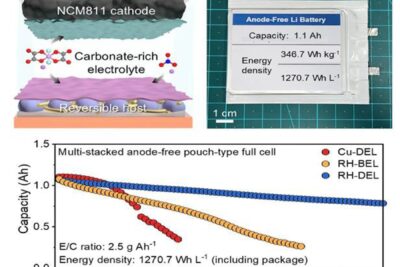

The main objective, however, is the development of a Si (graphite) -SnS2 composite anode that, according to the AIT Austrian Institute of Technology, ‘achieves a reversible capacity of 800 mAh/g over more than 1000 cycles.’ To do so, the MoSiLIB project uses new material processing that is based on the combination of spray drying and high-energy ball milling.

Spray drying essentially means spraying a liquid containing solids into a hot gas stream, so the liquid evaporates and the solids remain. The process is typically used to create anode materials for lithium-ion batteries. High-energy ball milling, on the other hand, is a process where solids are milled using stiff balls in a high-energy shaker mill, creating a powder.

The SnS2 anode has a heterostructure consisting of Si/Li2S and Sn/Li2S. According to the research institute, this buffers “the volume expansion of the anode particles and reduces agglomeration during charging cycles. This increases the battery life, which makes the composite anode particularly suitable for 3b generation LIBs with LNMO cathodes.”

According to the press release, another focus of the AIT is the “development and optimisation of processing methods for electrodes on a pilot scale.” It wants to use pilot plants to look at the scalability of the processes to enable the most sustainable and economical production of silicon-tin sulphide composite anodes.

On top of the AIT, which coordinates the project, the consortium also includes the University of Vienna, AVL List GmbH, Frimeco Produktions GmbH, Université de Liège, and the University of Ljubljana.

“With MoSiLIB, we are taking a decisive step towards sustainable and high-performance lithium-ion batteries,” AIT researcher Damian Cupid, who coordinates the project. “By combining innovative materials and environmentally friendly manufacturing processes, we can not only improve the efficiency of batteries, but also reduce their ecological impact. This is an essential contribution to the energy storage of the future and the further development of electric mobility.”

0 Comments