Comau presents new platform for cell forming in small series

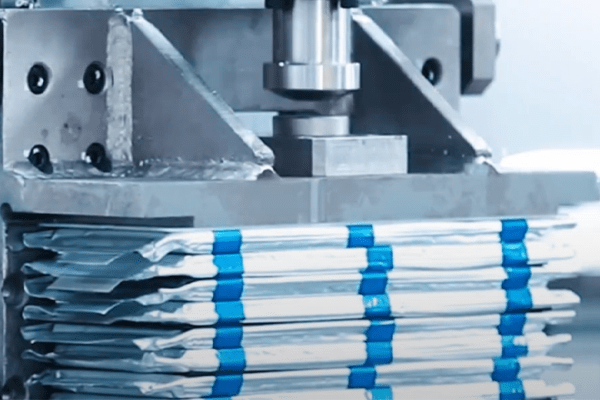

Comau‘s Lab Fixtures platform is a “modular and highly customizable battery cell forming platform designed for small series and laboratory applications”, the company described during its presentation. The solution was originally developed at the request of the National Institute of Chemistry in Slovenia, but is now offered to all customers.

The Lab Fixtures system for formation and testing should help speed up product validation in the laboratory and small-series production, therefore, shortening the time to market. Safety and efficiency are also said to have been improved.

At the Battery Show Europe (until June 5 in Stuttgart), Comau is also presenting solutions for battery production on a gigawatt scale. The ‘Racer-5 Sensitive Environments’, for example, is an articulated arm robot that has been specially developed for use in clean rooms and dry rooms. This makes the robot suitable for electronics production or sensitive processes such as battery cell forming in battery production.

Formation is the first charging process of the battery cell that has just been manufactured and filled with electrolyte. During this process, numerous reactions take place between the electrolyte and the materials of the electrodes, especially at the interfaces. This means that the forming process lays the foundations for numerous properties of the cells, making it an important component of production quality. If the forming process is not carried out well or precisely enough, the properties of the cell can deviate from the expected values, even though the right materials have been used.

“Comau has long been at the forefront of electrification, delivering best-practice technologies across the entire battery lifecycle to fully support the electrification transition, as reflected in the range of solutions shown here at The Battery Show,” says Stefania Ferrero, CMO of Comau. “This end-to-end approach enables our customers to address both current and future production challenges, which is why we continue to invest in new technologies capable of enhancing and accelerating the battery manufacturing value chain.”

0 Comments