Ford kicks off battery pack production in Cologne

Since last year, Ford has only produced electric vehicles at its plant in Cologne, Germany. Specifically, these are the Ford Explorer and the Capri, both of which sit on the MEB platform borrowed from Volkswagen. That means Ford has used the entire drivetrain – electric motor and batteries – from VW, as well as some components on the inside of the vehicle.

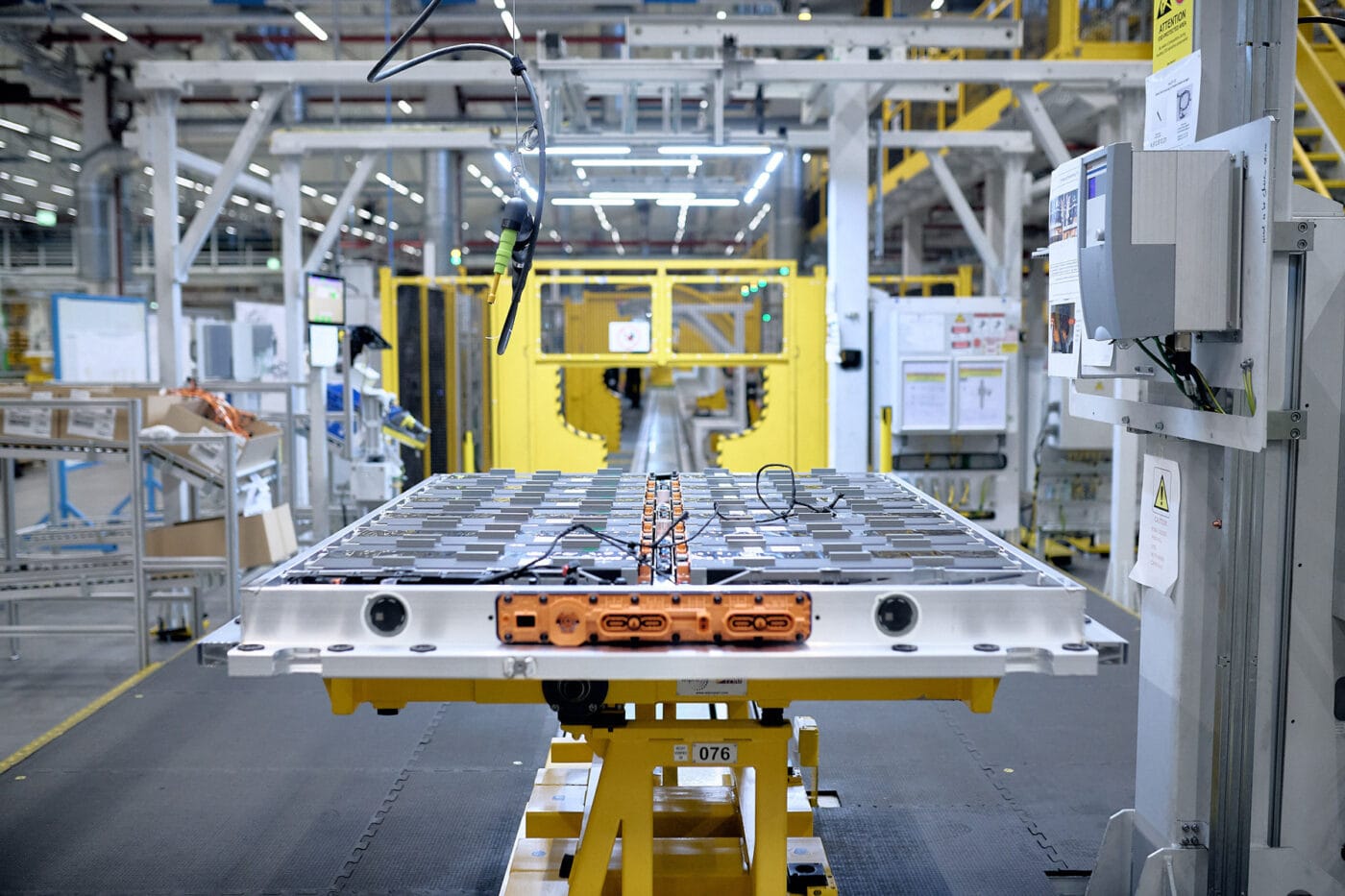

The batteries were made by Skoda in the Czech Republic, and Ford had plans all along to manufacture them on its own in Cologne. The former engine factory was thus converted to produce high-voltage batteries.

Ford now assembles three different drive battery configurations for the Ford Explorer and the recently revealed Ford Capri, namely variants with 52 kWh, 77 kWh and 79 kWh. The production line’s 180 state-of-the-art robots carry out welding, glueing and bolting operations to assemble the battery housing. Each unit incorporates up to 12 battery modules, with approximately 2,775 individual parts combined across the 2 km-long automated line.

The fully digitalised facility operates as part of Ford’s vision of a ‘Factory of the Future’. It is part of a $2 billion investment to modernise the long-standing Cologne plant. And with production taking place under one roof, the automaker aims to ensure tighter integration between battery pack and vehicle assembly, reducing transport emissions, optimising logistics, and maintaining high manufacturing standards.

Designed to enhance quality, reduce complexity and support employee upskilling, the facility also plays a strategic role in Ford’s electrification ecosystem. Alongside Cologne, electric drive units are being built at Ford’s Halewood site in the UK, while additional EV production is ramping up in Craiova, Romania, and Kocaeli, Turkey through Ford Otosan.

The mood among employees is currently anything but good, as May saw the first strike in the plant’s nearly 100-year history. This is due to the company’s austerity measures, which include job cuts and short-time working. Not only are sales of electric cars built in Cologne significantly below expectations, but Ford is also losing market share with combustion engine models from other plants. Furthermore, although the US parent company promised its German subsidiary a capital injection of up to 4.4 billion euros in March, it simultaneously withdrew an important guarantee.

1 Comment