Mercedes ramps up production of CLA drive units

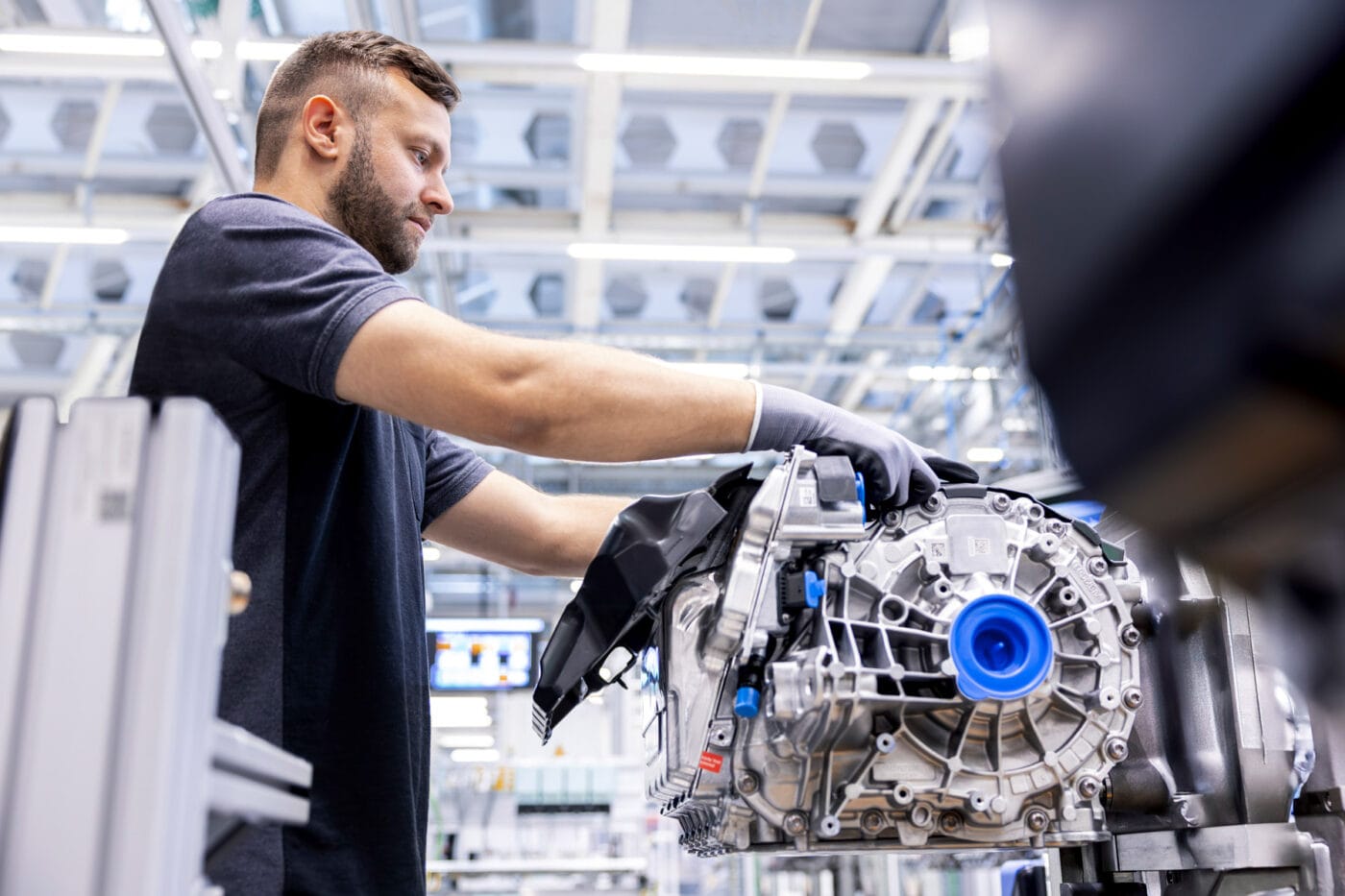

In preparation for the series production of the 800-volt sedan, the drive units have been manufactured for some time. However, now the Stuttgart-based car manufacturer is talking about a “successful ramp-up.” The production and assembly of the new components are ‘an important addition to the drive-flexible production portfolio of the traditional site’ – more on this in a moment.

When we talk about the drive units of the electric CLA, we are primarily referring to those on the rear axle, which are installed in the rear-wheel drive CLA250+ and the all-wheel drive CLA 350 4MATIC – Mercedes buys the additional front-axle drive of the all-wheel drive from a supplier. Only the drive unit on the rear axle is an in-house development, which is also manufactured in-house.

It is precisely this production that Mercedes is now giving some insights into how the company manufactures the electric drive system in the various factory parts along the Neckar. The power-transmitting wheelset and other components, such as the control unit, are manufactured in Untertürkheim, Mettingen and Hedelfingen. These components are then assembled into a complete system in Untertürkheim. From there, the journey continues a few kilometres to Mettingen, where the drive unit is installed in the electric axle, which is then delivered to the Rastatt vehicle plant as a pre-assembled complete system.

One kilometre of production line

While it is often said that electric drives are easier to manufacture, Mercedes emphasises the complexity of production. ‘The assembly line for the electric drive units at the Untertürkheim plant alone covers around 10,000 square metres, is around 1,000 metres long and consists of more than 200 manual and automated processes,’ the press release states. The line was set up in assembly hall 141, where combustion engines were previously assembled.

“Stuttgart-Untertürkheim epitomises the drive of Mercedes-Benz. The location also stands for its drive flexibility,” said Jörg Burzer, member of the Mercedes Board of Management responsible for Production, Quality and Supply Chain Management. “With the production of components for the new CLA, it underpins its role in the global Mercedes-Benz Powertrain production network. With new, future-proof high-tech products, Untertürkheim is ready to continue its 120-year success story.”

It is not only for the CLA based on the new MMA entry-level platform that the electric drives will be manufactured in Untertürkheim: In a new works agreement, the company management and works council have also designated the main plant as one of the production sites for drive systems for the future top-end segment – the electric motors for the luxury series will therefore also come from Stuttgart in future. Battery assembly will also be added to the Brühl plant.

“Untertürkheim is and will remain the lead plant for drive technologies. The electric drive units for the CLA belong here just as much as the new products for our top-end segment,” says Michael Häberle, Chairman of the Works Council at the Untertürkheim site and Deputy Chairman of the General Works Council. “The heart of the automobile comes from Untertürkheim – that is our enduring tradition and our promise for the future and coming generations. The new works agreement emphasises the importance of Untertürkheim as a central production site for our innovative drive technologies.”

mercedes-benz.com (in German)

1 Comment