AIT launches research into anode material based on silicon and tin sulphide

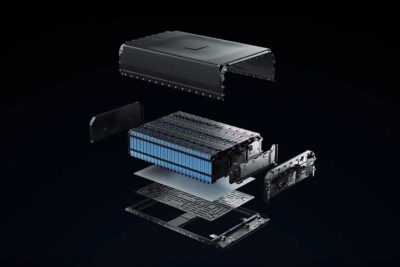

The project title RESTINA stands for ‘Recovered Silicon / Tin Sulphide Nanocomposite Anode Materials for Generation 3b Lithium Ion Batteries’. The aim of the project is to develop high-performance and environmentally friendly anode materials based on silicon and tin sulphide for generation 3b lithium-ion batteries. This term refers to batteries that, in contrast to current electric car batteries, have a higher energy density, improved cell chemistry and improved battery management. Additionally, next-generation batteries should age more slowly and allow for more charging cycles.

The AIT describes the desired material mixture of nanocomposites made from recycled silicon (obtained from disused photovoltaic modules) and tin sulphide (SnS2) as the technological core of the project. According to the Austrians, this novel approach combines the high specific capacity of silicon with the good electrical conductivity of tin compounds. At the same time, the project partners want to bring their basic concepts from the laboratory closer to industrial requirements. For example, the technological innovation should ensure greater environmental compatibility and sustainability of anode materials.

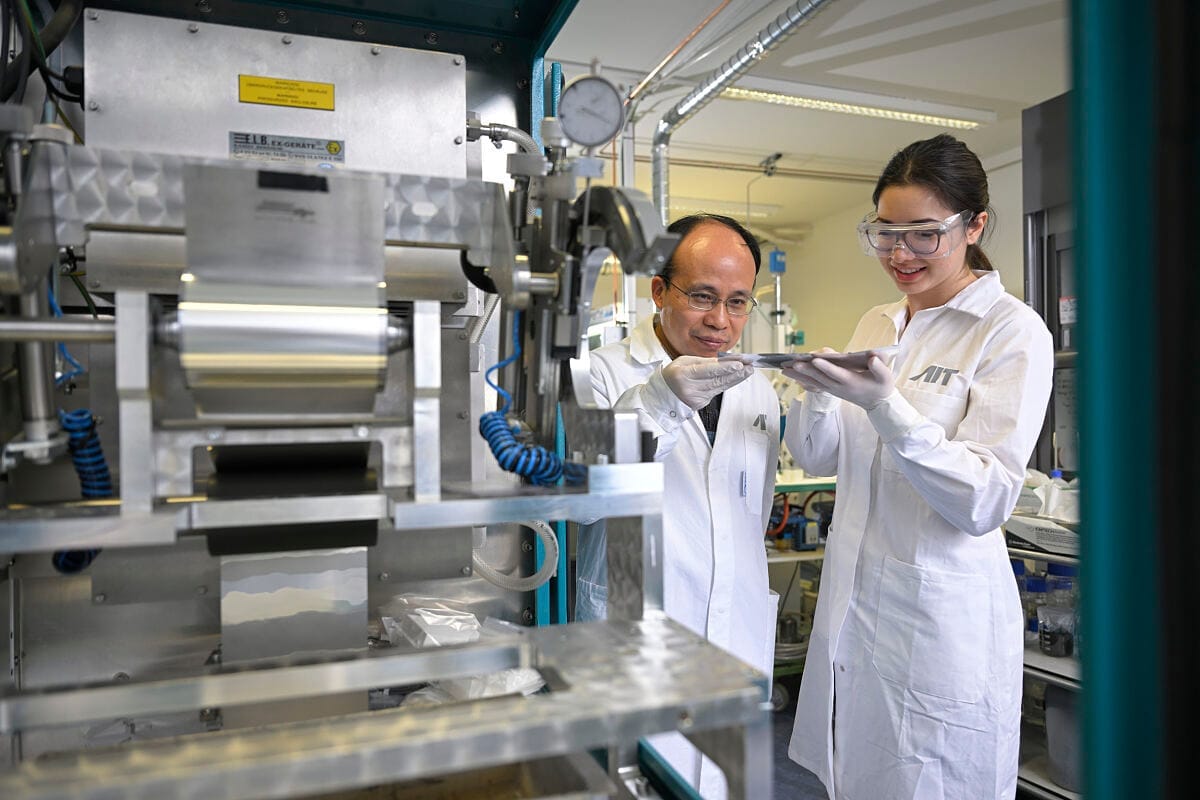

“In battery research, we are faced with the challenge of bringing together material performance, industrial feasibility, and environmental responsibility,” explained Dr Damian Cupid, Senior Scientist at the AIT Austrian Institute of Technology and project manager of RESTINA. The project is pursuing precisely this integrated approach: “We combine recycled silicon with innovative materials chemistry and sustainable processing to develop a new class of high-performance anode materials for future battery generations. The project shows how materials research can make a concrete contribution to the energy transition – from the idea to the pilot cell.” In addition to the AIT Austrian Institute of Technology, Frimeco Produktions GmbH, the University of Vienna and the University of Liège are also involved in the project.

The RESTINA participants are also looking at the technological details: when charging the battery, heterostructures are to be created at the interface of the anode particles (‘Si/Li₂S and Sn/Li₂S’), which have the function of cushioning mechanical stresses – caused by the change in volume of the active materials – and improving the long-term stability of the anode. With this novel approach, the project team says it is specifically trying to address the challenges of conventional Si-based anodes. These include particle breakage, instability of the SEI (solid electrolyte interface) layer and low conductivity.

To produce the Si/SnS2 composites, the researchers are evaluating two complementary, industrially scalable manufacturing processes: a solvothermal process in environmentally friendly solvents and so-called high-energy ball milling. With a view to environmental compatibility, the initiators also want to develop carbon-based protective coatings that stabilise the particle surfaces. “These coatings not only enable safe handling in air (without the release of toxic gases such as H₂S), but also water-based processing of the electrodes – an important step towards green battery technology,” writes the AIT. This approach also allows the electrode materials to be recycled later in aqueous media without harmful side reactions.

At AIT itself, the Si/SnS₂ nanocomposites are both developed and scaled up to an industry-compatible production level. In addition, the new anode materials (in combination with nickel-dominated cathode materials) are being used to produce generation 3b pouch cells with capacities between 2 and 5 Ah. Together with the University of Liège, the AIT is also investigating the electrochemical ageing mechanisms of the materials. The University of Vienna is providing fundamental findings on phase diagrams, crystal structures and thermodynamic properties of the Si/SnS₂ system. Industrial partner Frimeco is contributing its expertise in the scalable synthesis and coating of the nanocomposites.

0 Comments