Ford Universal EV Platform: Ford announces ‘Model T moment’ for electric cars

Ford plans to assemble the pickup at its Louisville plant in the US state of Kentucky – the same location where it presented the new EV platform. The as-yet-unnamed model is scheduled to reach customers in 2027. It is not the pickup currently developed under the codename T3, which will be built at the BlueOval City plant in Tennessee – its production start was recently pushed back to 2028.

Ford calls the new mid-size pickup “a new idea for a new era,” but has so far revealed few technical details. With a targeted entry price of $30,000 (currently about €25,800), the pickup is set to “be as quick as a Mustang EcoBoost”, completing the sprint from 0 to 100 kph in about five seconds. At the same time, “it will have more passenger volume than a 2025 Toyota RAV4,” And it comes with a truck bed and a frunk for more cargo space. “You can lock your surfboards or other gear in that bed – no roof rack or trailer hitch racks required,” the US carmaker promises.

The entry-level version, priced at $30,000, will use LFP cells from US production – albeit with Chinese technology. Ford plans to produce the prismatic cells at its BlueOval Battery Park Michigan. The LFP battery plant will have an annual capacity of 20 GWh, with production due to start in 2026. Ford will license the technology from Chinese battery giant CATL.

Smaller LFP battery in the base model

Ford revealed one notable detail about the pickup’s battery at the press event in Kentucky: it aims for a unit about 15 per cent smaller than that in the BYD Atto 3 built in China. The Atto 3 has a 60.5 kWh LFP battery – meaning the Ford pickup’s base version would come in at around 51 kWh. That’s a capacity often found in compact EVs under 4.50 metres long, but not in larger pickup trucks.

Ford has yet to disclose an EPA range target. There will also be a larger battery option using NMC chemistry, but no figures on its capacity are available. Both battery variants will operate on a 400-volt system – a cost-driven choice. More important to the developers than an 800-volt system was bidirectional charging: according to Ford CEO Jim Farley, the platform will support Vehicle-to-Load (V2L) and Vehicle-to-Home (V2H).

Doug Field, Ford’s Chief EV, Digital and Design Officer, insisted the model “isn’t a stripped‑down, old‑school vehicle” – likely a jab at startup Slate Auto’s budget electric pickup, which forgoes features like electric windows. Ford even sees historic significance in the new model. “We took inspiration from the Model T – the universal car that changed the world,” Field said. “We assembled a really brilliant collection of minds across Ford and unleashed them to find new solutions to old problems. We applied first‑principles engineering, pushing to the limits of physics to make it fun to drive and compete on affordability.”

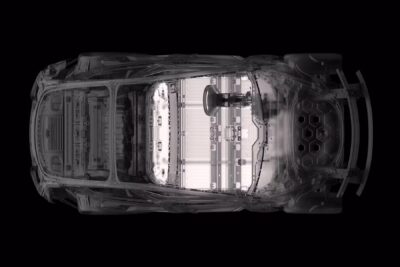

The Model T link, as the first car built on a moving assembly line, is also evident in how Ford will manufacture the Universal EV Platform. Instead of a traditional line, Ford will use an “assembly tree”: three submodules – the front, rear, and middle section with the battery – are pre-assembled on separate lines, then joined together only near the end of production. Each submodule will be made from large one-piece aluminium unicastings. This approach not only improves ergonomics for assembly workers but, according to Ford, can cut assembly time by up to 40 per cent compared to current Louisville models. “Some of that time will be reinvested into insourcing and automation to improve quality and cost, ultimately netting a 15% speed improvement,” Ford says.

Overall, the new platform reduces the number of parts per vehicle by around 20 per cent, uses 25 per cent fewer fasteners and requires 40 per cent fewer workstations in assembly. The wiring harness will be 1.3 kilometres shorter and ten kilograms lighter than in a current Ford electric SUV. Ford also promises customers lower operating costs over five years than those of a three-year-old used Tesla Model Y.

No further models announced – yet

So far, Ford has only given concrete details for the mid-size pickup. No other models based on the platform have been officially announced. However, the Kentucky-built pickup is planned for export, though markets have not been confirmed. An animation shows potential variants including a smaller electric SUV, a larger SUV with three rows of seats, and a van. Currently, only the Kentucky plant is being retooled for the new production system, with a $2 billion investment – though more sites are likely to follow.

We took a radical approach to a very hard challenge: Create affordable vehicles that delight customers in every way that matters – design, innovation, flexibility, space, driving pleasure, and cost of ownership – and do it with American workers,” said Ford President and CEO Jim Farley. “We tore up the moving assembly line concept and designed a better one. And we found a path to be the first automaker to make prismatic LFP batteries in the U.S.”

ford.com (presentation), ford.com (production system), insideevs.com (battery)

This article was first published by Sebastian Schaal for electrive’s German edition.

0 Comments