Altilium and JLR demonstrate UK’s first EV cells from recycled materials

Altilium and JLR first announced their partnership in September 2024 to test Atilium’s pouch cells using recycled materials at the JLR’s battery test facilities. Now, the companies will showcase “the newly developed automotive grade NMC 811 multilayer pouch cells that were successfully manufactured using Cathode Active Material (CAM) recovered from end-of-life EV batteries using Altilium’s EcoCathode process” at the Cenex Expo in the UK.

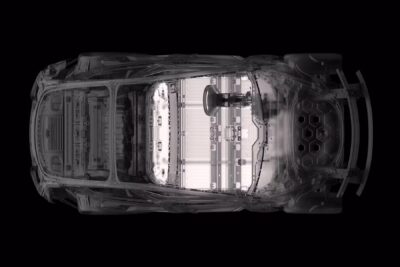

Visitors can also explore a virtual reality model of the Jaguar I-PACE battery pack, showing how the recycled cells integrate into vehicle design.

The cells were produced using cathode active material (CAM) recovered from end-of-life electric vehicle batteries at the company’s Devon facility. The company’s proprietary EcoCathode process reportedly achieves recovery rates above 95% for critical raw materials such as lithium, nickel and cobalt, and was shown to produce cathode materials with high purity, consistency, and manufacturability. The units are undergoing full validation at JLR’s battery testing facilities.

The project, supported by the Advanced Propulsion Centre UK (APC) under its Advanced Route to Market Demonstrator initiative, aims to validate the use of recovered materials in high-performance EV batteries and strengthen the domestic supply chain. Earlier this year, Altilium completed large-scale EV battery cell manufacturing trials using recycled cathode materials. At the time, the British clean technology company already stated that it demonstrated that lithium-ion cells made with Altilium’s EcoCathode NMC 811-2036 CAM perform comparably to those using conventional mined materials.

Altilium’s EcoCathode process is said to recover over 95% of cathode metals and more than 99% of graphite. The materials are upcycled into high-nickel CAM for direct reuse, while graphite is further purified for anodes. The project supports compliance with upcoming EU battery regulations, reducing risk for UK exports and enhancing supply chain resilience.

Dr Christian Marston, COO and co-founder of Altilium, said: “This is a major technical breakthrough and a vote of confidence in the UK’s ability to lead in battery recycling. Recycled materials can meet automotive performance standards while dramatically reducing emissions and reliance on imported raw materials.”

“This project reinforces JLR’s leadership in sustainable innovation,” said JLR project lead David Sellick. “Batteries are the largest contributor to an EV’s carbon footprint, and this initiative shows that performance and sustainability can coexist.”

This comes as new EU Battery Regulations mandate minimum thresholds for recycled content in EV batteries. Altilium is scaling up its operations with its recently opened ACT 2 facility in Plymouth, the UK’s first commercial EV battery recycling site, and the upcoming ACT 3 plant, which will recover battery minerals from up to 24,000 vehicles annually.

0 Comments