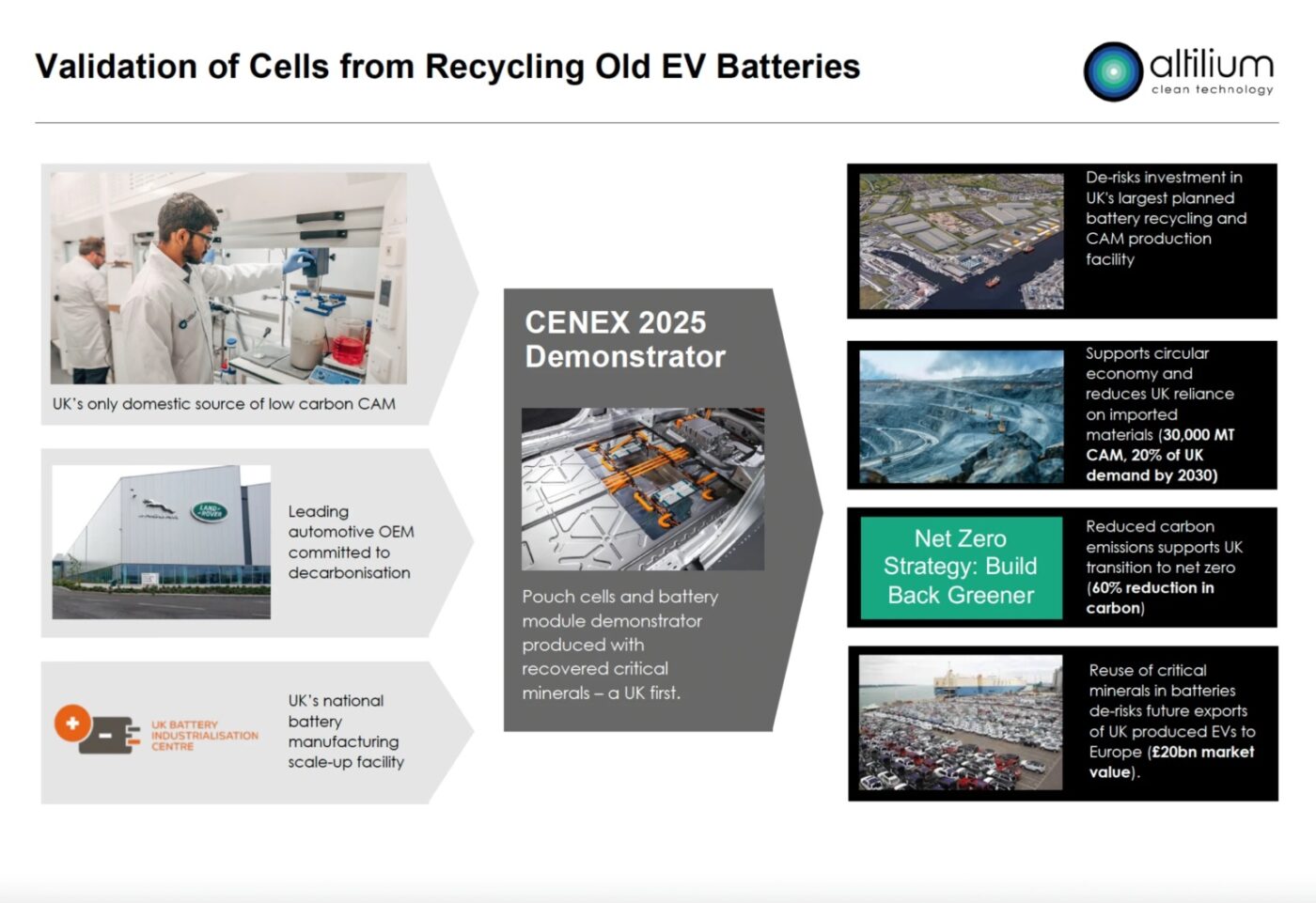

Jaguar Land Rover to test Altilium batteries with recycled materials

According to Altilium, JLR intends to validate pouch cells produced by Altilium using recovered cathode active materials in its battery test facilities that will eventually be used “in vehicles with a leading automotive OEM.”

The battery pouch cells are being produced at the UK Battery Industrialisation Centre (UKBIC), using recovered battery materials produced by Altilium at its new mini-commercial ACT facility and ACT1 Pilot, both of which are in Devon, southwest England.

“We are proud to lead this pioneering project with JLR that brings us one step closer to a circular economy for battery materials in the UK,” commented Dr Christian Marston, Altilium COO. “By demonstrating that EV battery cells made from recovered materials can meet the rigorous standards of the automotive industry, we’re not only reducing the environmental impact of battery production but also supporting the UK’s efforts to build a more sustainable and resilient EV supply chain.”

Altilium uses its own ‘EcoCathode’ process to convert end-of-life EV batteries and manufacturing scrap into domestic, sustainable battery precursors, cathode active materials (CAM) and cathode precursor (pCAM) for direct reuse in new batteries.

Altilium’s first mini-commercial plant is currently under construction in Plymouth in the southeast of England near Devon, while its planned Teesside plant in northeast England, will be one of the largest EV battery recycling facilities in Europe. At the EV battery recycling hub in Teesside, the company intends to provide around 20 per cent of the UK’s cathode active materials (CAM) demand in 2030. The company cites a processing capacity of 50,000 tons of ‘black mass’. The new plant can process various battery chemistries, such as LFP, NMC, and LCO.

According to Benchmark Mineral Intelligence, the vast majority of battery recycling ‘black mass’ from around the world currently travels via Southeast Asia and into China, which has a mature EV battery recycling infrastructure. With the nascent recycling industry in the UK and growing numbers of electric vehicles, the UK will be able to keep critical raw materials such as lithium, cobalt, and nickel within ever-renewable loops within its own industries.

Altilium is by no means alone in pushing for domestic battery supply chains with sustainable loops. Just this week, another UK battery recycling company, EMR, announced the opening of its facilities in Birmingham, England.

0 Comments