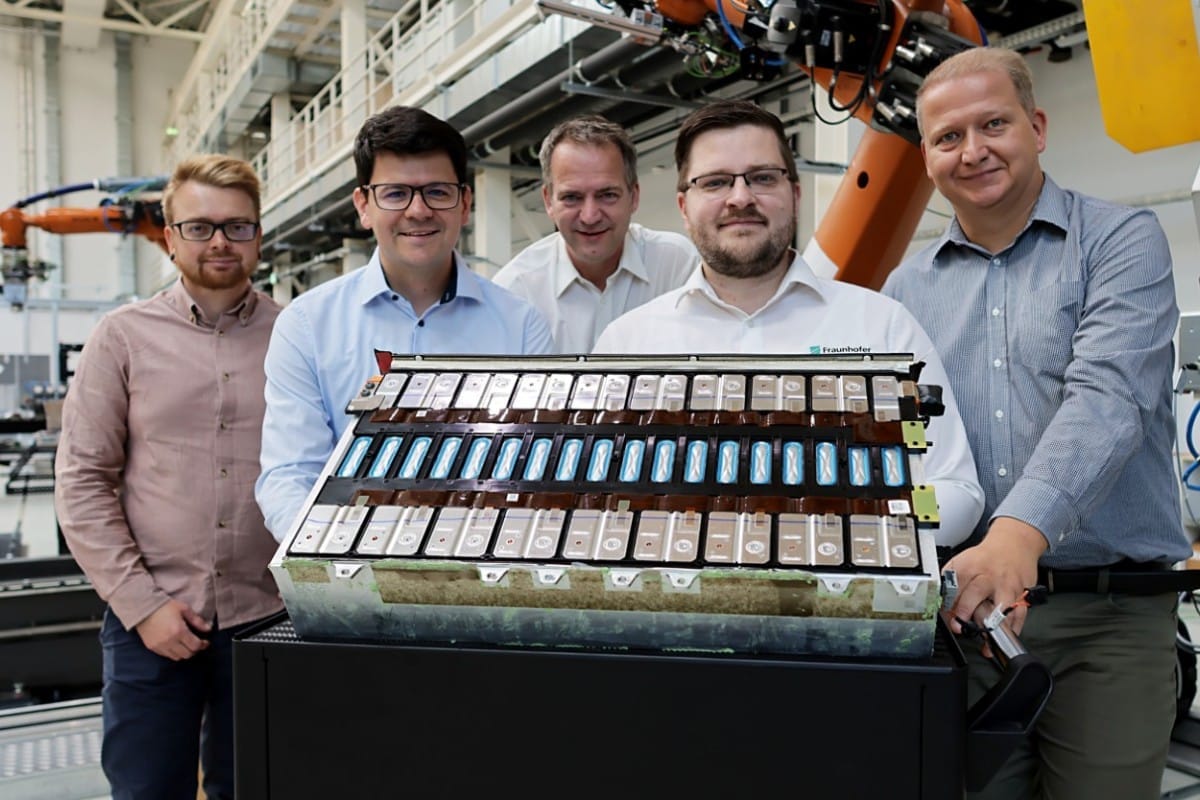

Fraunhofer pilot plant carefully dismantles batteries down to the cell level

The system designed by Fraunhofer researchers and EDAG is intended to enable batteries to be dismantled safely and economically, even if the HV storage devices are still functional and therefore need to be handled with care. The project focuses on batteries that have too little residual capacity for further use in vehicles but still have cells that could serve well when bundled into large storage systems in private households, companies or at electricity grid operators.

“Shredding used modules or entire high-voltage storage systems would thus waste valuable resources. By repairing and remanufacturing these batteries, not only can precious resources be preserved, but the lifespan of the components can also be extended,” wrote the project partners. “Cells that have been specifically refurbished and repurposed for new applications can be ready for long-term use again.” How components and cells can be removed from a traction battery without costs spiralling out of control is now the subject of a joint initiative between Fraunhofer IWU and EDAG Production Solutions.

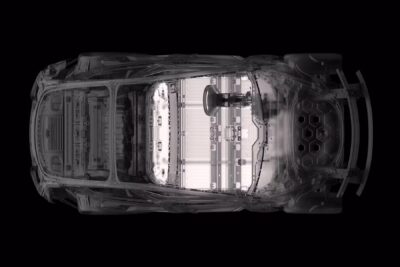

The future pilot plant in Chemnitz is at the heart of the project and, in view of the immense demand for used battery recycling in the future, is intended to demonstrate an alternative to the current recycling and shredding of batteries. Fraunhofer IWU and EDAG envisage “largely damage-free disassembly of all components down to the cell level.” This is a prerequisite for a new battery life, thanks to the replacement of defective or aged cells or modules.

It is precisely this type of dismantling that the new plant in Chemnitz is intended to enable. It relies on “variant-flexible, AI-supported dismantling.” An integrated system for analysing the health status of modules and cells is designed to ensure that only reusable components are approved for reuse (completely intact units can even be used for new traction batteries). Battery cells that can no longer be reconditioned, on the other hand, are to be sent for recycling in order to recover raw materials such as lithium and cobalt.

According to Fraunhofer IWU, the new infrastructure also serves as a data platform for standardising reuse and recycling processes. The data collected will also form the basis for the further development of qualification profiles for skilled workers in the German state of Saxony.

This article was first published by Cora Werwitzke for electrive’s German edition.

0 Comments