ZF Foxconn inaugurates plant in Hungary and manufactures e-axles for BMW

The company, previously known only to industry insiders, is fully named ZF Foxconn Chassis Modules, also abbreviated as ZFFCN. It was formed from the ZF subsidiary ZF Chassis Modules, in which the Taiwanese contract manufacturer Foxconn acquired a 50 per cent stake in spring 2024. Foxconn is reported to have invested around 500 million euros for this share.

When the partnership was announced in summer 2023, former ZF CEO Holger Klein stated: “With Foxconn, we have gained a strong strategic partner with whom we can open up new perspectives and opportunities for the ZF Chassis Modules GmbH. ZF as a globally active automotive supplier and Foxconn as a leading electronics manufacturer, complement each other excellently to jointly open new customer groups and expand its presence, especially in growing markets.” The move was part of the strategy ‘to grow specific business areas of ZF with the support of external partners beyond current limits,’ Klein added at the time.

Foxconn targets the automotive sector

Foxconn, renowned worldwide as the contract manufacturer of Apple’s iPhone, is an exciting partner for ZF. The company has ambitious plans for the automotive sector and aims to replicate its iPhone business model in vehicles. To this end, Foxconn has already presented several of its own prototypes, which could serve as the basis for customer vehicles, and has already secured Mitsubishi as a partner.

Activities as a supplier – such as the current joint venture for passenger car chassis systems with ZF Friedrichshafen – are therefore perfectly timed to establish Foxconn as a key player in the industry. After all, ZF Chassis Modules already employs around 4,000 staff across 27 sites worldwide.

550 new jobs in Hungary

The number of jobs is set to increase further: by 2027, around 550 new jobs are expected to be created for the e-mobility cluster in Hungary, both at the new factory in Debrecen and at another new plant in Kecskemét. The new production facility in Debrecen was built in just 13 months at a cost of 26.7 million euros.

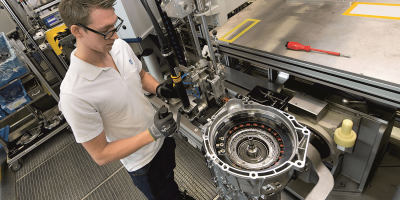

The plant manufactures electric front and rear axles for BMW’s Neue Klasse, including the new iX3, using just-in-sequence production. Each axle undergoes 22 to 24 assembly steps on a highly automated production line. The facility also uses a fleet of automated guided vehicles (AGVs) to support intralogistics.

The plant covers over 15,000 square metres, with 14,500 square metres dedicated to storage and production. The factory operates exclusively on renewable electricity.

0 Comments