The ID. 3 to lead Volkswagen’s “system change”

Volkswagen celebrated the production of the first produced ID.3 with a ceremony attended by German Chancellor Angela Merkel. The Zwickau plant is to become the largest electric car plant in Europe. At the same time, VW representatives called for a stronger commitment to the clean energy revolution.

A white ID.3 – the first production vehicle – upon which Volkswagen is pinning its hopes. At the start of series production, VW boss Herbert Diess did not scrimp on praise or superlatives. Even the Zwickau location is apparently “where our future begins”. There was a lot of pathos in Saxony today.

“The ID.3 will make an important contribution to the breakthrough of e-mobility,” Diess said. “It makes clean, individual mobility accessible to millions of people.” The ID.3 is a “car for the middle of society, just like the Golf”.

In his short speech, Diess admitted that the ID.3 was not the first electric car, but the first in “outstanding manufacturing quality” and at the price of a comparable combustion engine – and the first electric car to be produced in a balance sheet CO2-neutral way. According to VW, the ID.3 will reach customers without a “CO2 backpack” – the production of the vehicle itself in Zwickau should also be as green as possible. The energy-intensive battery cell production is to be carried out using only green electricity; unavoidable emissions are to be offset, among other things, by supporting the climate protection project “Katingan Mataya Forest Protection” on the Indonesian island of Borneo.

“Today we can say that Zwickau is a cornerstone of German automobile production,” said Chancellor Merkel. “But we can also say that Zwickau is a cornerstone of the future of automobile production.” This is supposed to be a fundamental change in the industry and a paradigm shift in mobility.

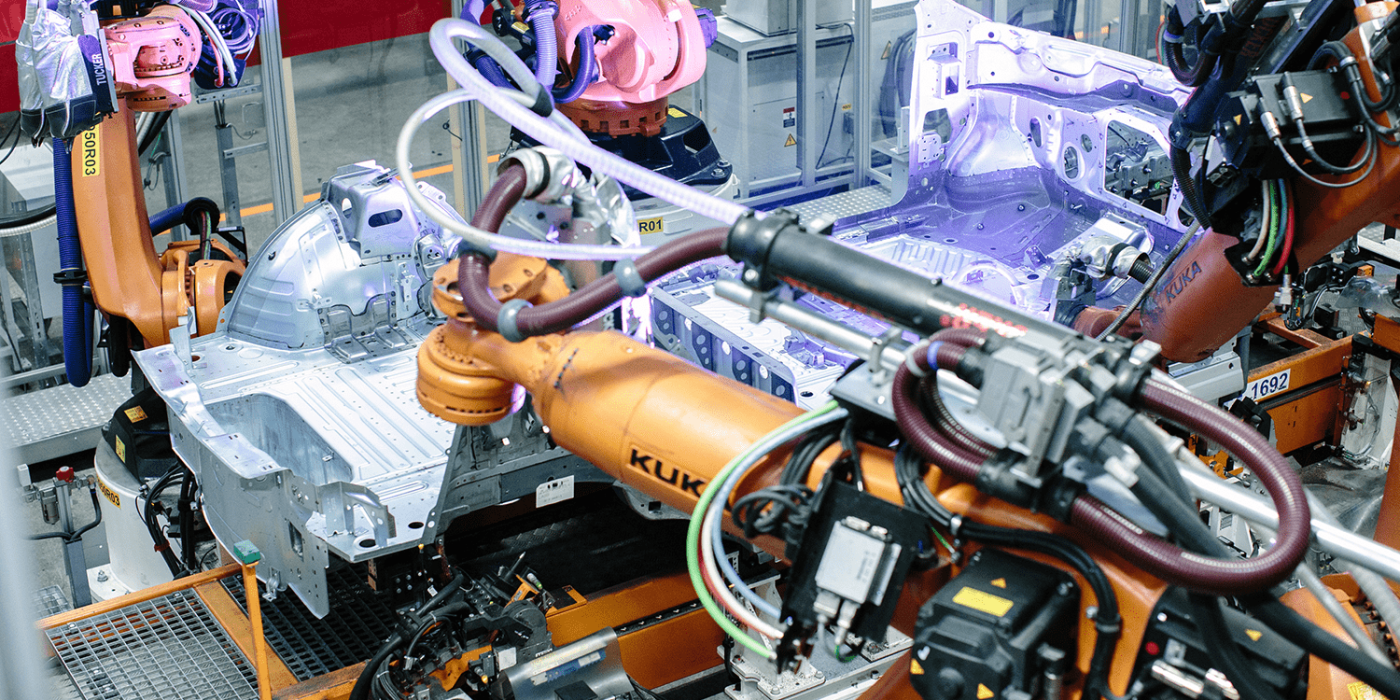

The area of Zwickau in the German state of Saxony is particularly proud to be the first VW factory to switch completely to e-mobility. The investments for the conversion amount to around 1.2 billion euros. In the final expansion stage from 2021, six MEB models for three Group brands will be built in Zwickau – up to 330,000 vehicles per year.

In addition to production at the Zwickau plant, the component plants in Braunschweig, Kassel, Salzgitter and Wolfsburg will also contribute to the manufacture of the ID.3. These other plants manufacture important components such as the electric drive or the battery system. The Emden and Hanover vehicle plants are also to start producing electric cars from 2022. The Volkswagen Group also plans to set up a Giga factory for battery cells with Northvolt in Salzgitter.

“Germany must be the driver of change and master the entire e-mobility value chain,” Diess said. “That’s why we produce electric cars in Germany and have also decided to develop and produce electric machines, battery cells and systems. In the immediate future, a strong e-car cluster will emerge in Germany.”

In his speech, Diess reaffirmed the company’s exclusive focus on battery-electric cars. He rejected the fuel cell in passenger cars and synthetic fuels because of its energy-intensive production – this would be too expensive for the mass market in the foreseeable future. “It is no longer a question of whether the electric car will prevail, but where in the world and how quickly,” Diess said.

He also highlighted the MEB as a purely electric platform, as it was the only way to “take advantage of the benefits of modern electric mobility” and not “make the numerous compromises” that a mixed platform with combustion engines would require. This was a bit of a jab at Volkswagen’s competitors in the business of mass production such as PSA, but also to Daimler and BMW. BMW, Diess’ former employer, recently defended its strategy of focusing on a multi-energy architecture. “You won’t notice any differences – maybe two kilograms more here or there. But that’s not decisive for the customer,” said BMW boss Oliver Zipse.

Politicians do not seem to care so much whether a platform is purely electric or accommodates mixed technology with combustion engines. For the Chancellor, other things count. “The mobility we have seen so far emits far too much CO2,” says Merkel. “This also means for us as politicians that we have to set new standards. Electric mobility is only the turnaround if we also switch to electricity from renewable energy”.

“We must turn two important screws to achieve the breakthrough,” said Merkel. “On the one hand, this means charging infrastructure, and on the other, we must create incentives for the purchase of electric cars.” Among other things, Merkel promised simpler permits for charging points.

Merkel and Diess will continue to discuss the charging infrastructure and purchase premiums: Following the ceremony in Zwickau, both went to Berlin – to the car summit at the Chancellery. “Tonight at the Chancellery we can set the course for the breakthrough of electromobility,” Diess said.

Translation of an original article by Sebastian Schaal

0 Comments