Volkswagen launches pilot production ahead of Gigafactory

The Volkswagen-Northvolt cooperation is taking off as they launch a first pilot production for battery cells at Volkswagen’s Salzgitter plant. Production is to scale up to 16 GWh at the end of 2023 with Volkswagen investing around €1Bn.

Volkswagen is aiming to independently produce its own battery cells in a joint venture with Northvolt, rather than having to rely on battery systems from suppliers. At the Salzgitter plant in Germany where TDI and TSI engines are now rolling off the assembly line, the Center of Excellence (CoE) is already established with an initial 300 employees.

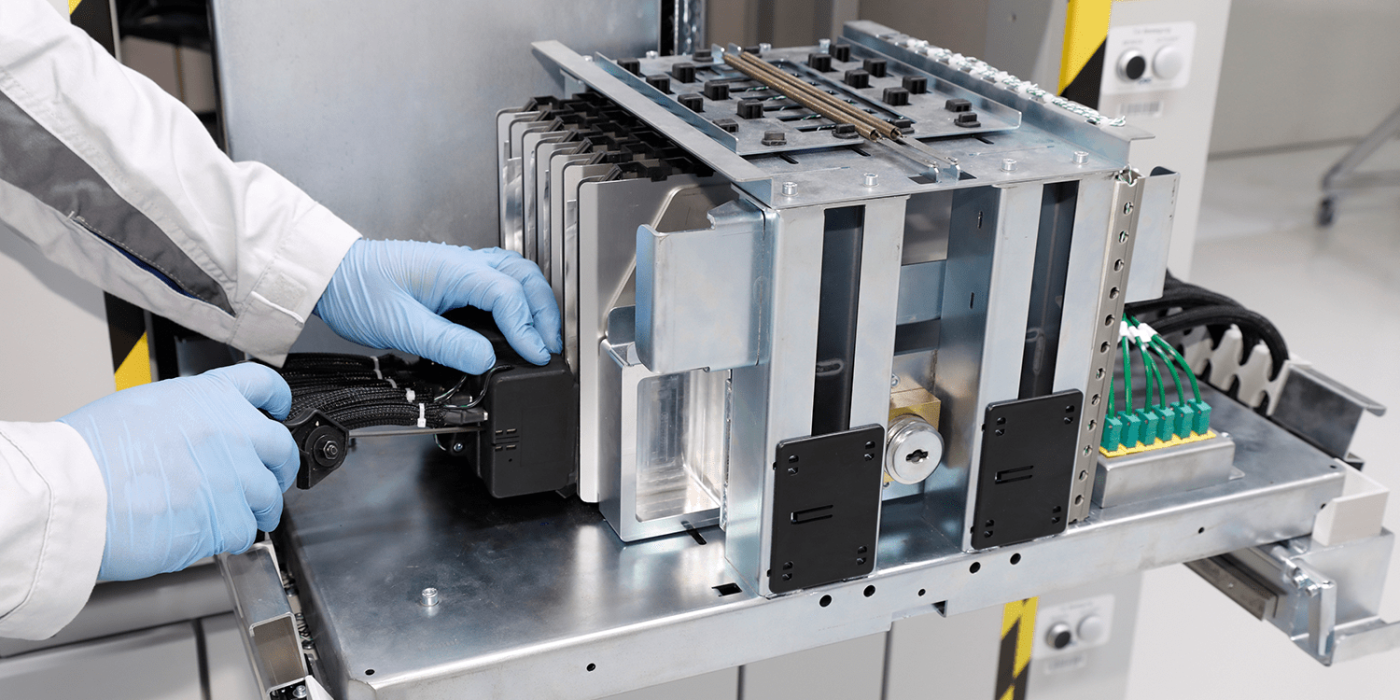

Volkswagen today opened a pilot production facility as part of said CoE with the goal of testing, development and small-series production of battery cells. For Frank Blome, head of the CoE for battery cells, the pilot plant is “an important step on our way to building the gigafactory”. Performance, costs and quality should be secured in order to “master the entire value chain of lithium-ion batteries from raw materials through production to recycling”. The series cell from the joint venture with Northvolt will have a gravimetric energy density of around 300-watt hours per kilogram. Needless to say, solid-state batteries will be investigated, said Blome.

The Gigafactory will be set up through the joint venture between Volkswagen and Northvolt of which 50 per cent owned by each of the partners. In addition to the existing 300 employees at the CoE, another 700 jobs will be created. This means that a total of 1,000 new jobs will be brought to the place that has recently borne the brunt of the fallout from the “dieselgate” affair, the scandal that is only called the “diesel topic” at Volkswagen. It seems to be a logical step to venture the transition to the new world in this location.

According to Volkswagen, the company will be taking on end-to-end responsibility for the battery-making process. This will be made possible by the consistent control of battery cells throughout the entire value chain: from installation in the battery system, for example of the ID series (“1st Life”), through Second Life (stationary storage, etc.) to recycling. Recycling will not be based on so-called thermal recycling, i.e. actual incineration, but on a process based on decomposition under inert gas.

This in turn strongly reminds of what electrive experienced at the German battery recycling firm Duesenfeld in January. From industry circles, electrive has also caught wind of a potential patent dispute. At the Volkswagen-Northvolt battery production site, the recycling recovery rate is supposed to be over 90 per cent – whereby only 50 per cent recycling by weight is currently required by law. Either way, Volkswagen wants to serve and control the entire battery field. “A completely new industry must emerge from the immense quantity we need,” says Dr Stefan Sommer, Member of the Board of Management for Components and Procurement at Volkswagen AG, and it sounds like a promise.

A comparison with Tesla, for example, shows that this announcement can only be the first step. Tesla’s Gigafactory 1 in Nevada (USA) is expected to reach an actual output of 36 GWh by 2020 at the latest. Should Volkswagen come even close to the range of the planned 25 per cent market share of battery electric cars in 2025, the cars they make themselves will not suffice. This would correspond to about 150 GWh per year, i.e. about ten times as much as the factory in Salzgitter is currently intended for. This means that further double-digit billion investments will be necessary. As is so often the case in large-scale industry, this will become a matter of ramping up the number of units: Start small, optimise the processes and then really go for mass production.

Frederik Hedlund, designated CEO of the joint venture with Northvolt, who was also present at the opening said: “We want to build the world’s most sustainable and environmentally friendly battery”. The “Green Battery” should also have a competitive advantage: The electricity used for production will come from renewable energy, and the supply chain for the raw materials should adhere to ethical standards. Public attention is increasingly focused on such issues.

Translation into English from original German article by

0 Comments