Tesla Battery Day: ‘tabless’ 4680 cell and a $25k car

The long wait has come to an end as the Tesla Battery Day is over, and what did we get? Silence, at first, as viewers from around the world watched the stream with no audio. Then, we got some of the expected news with more detail and articulated ambitions, and a promise of a 25k Tesla car.

The Tesla Battery Day had been on the agenda since spring when it first got delayed with no reason and then due to the encroaching pandemic. When it finally happened today, it was on the back of the company’s annual shareholder meeting. Let’s say, the wait increased the suspense.

So here are the essentials: Tesla has confirmed in-house battery cell production tonight. The new cells designated 4860 are bigger and claimed to be better, not the least because of advances in production. The key will be the use of a dry electrode, to rely primarily on nickel, and a ‘tabless’ design. The cells will also integrate into the vehicle as an entirely structural component.

The overall goal is a range increase of up to 54% and simultaneous reductions in kWh price by 56% and the investment per GWh by 69%. The 56% cost reduction would bring Tesla within reach of $50/kWh battery price, an instant analysis from our colleagues at P3 consultancy revealed.

This reduction in battery price would also make the mentioned promise of Elon Musk of a 25,000 dollar electric vehicle possible. He reckoned, three years from now, if the advances presented on Battery Day today materialise in time.

Also impressive is the long-term plan of a total Tesla battery output of 100 GWh by 2022 and 3 TWh by 2030 – that’s “supplemental to what we buy from our usual suppliers,” the Tesla boss was quick to add.

Elon Musk has said as much ahead of the big day. On Twitter, he had assured the expectant crowd 24 hours ago that nothing would happen – just yet. “We intend to increase, not reduce battery cell purchases from Panasonic, LG & CATL (possibly other partners too). However, even with our cell suppliers going at maximum speed, we still foresee significant shortages in 2022 & beyond unless we also take action ourselves.”

So indeed, Battery Day brought said action plan. Tesla has thrown ambitious targets behind previous guesses, as usual, this time followed up by serious engineering details and possible advances in manufacturing.

Down to the details

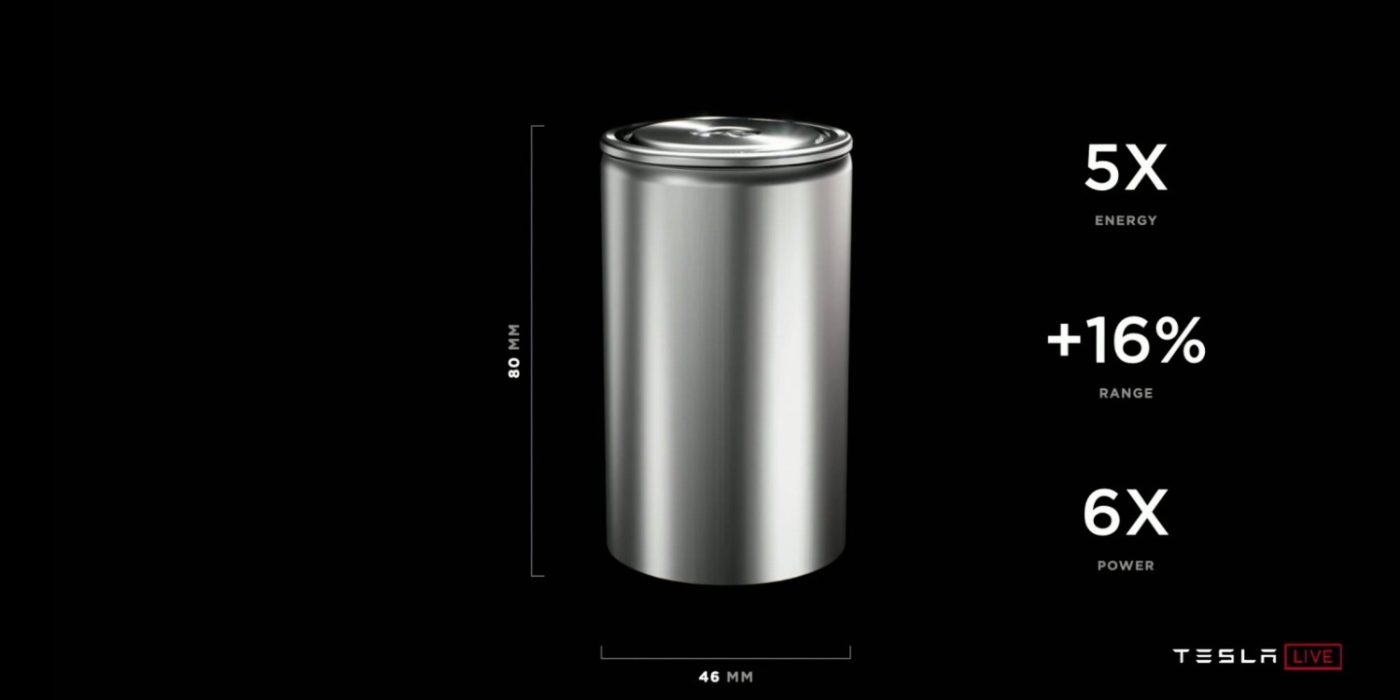

The new 4680 cells remain the biggest news with Tesla introducing a new cell format. As usual, the numbers designate the size of the cylindrical cells with a diameter of 46mm and 80mm height. They claim, these offer six times the power of Tesla’s previous cells and five times the energy capacity. This could result in a range increase of around 16 per cent, through cell design alone, stressed Elon Musk.

The said design also does away with the tab, that connects the cell and what it is powering. And while the cells are larger, eliminating the tab allows electrons to get around inside the cell easier and faster than in the current 2170 cells. “You actually have a shorter path length in a large tabless cell than you have in a smaller cell with tabs,” Musk said.

What’s more, Tesla claimed the “tabless” cells would accelerate the production process as it eliminates the need for the production lines to pause to add the tabs. Increasing the pace of production has been on their agenda since the days of Panasonic delays.

Production and efficiency increases was a recurring theme in the presentation, but the guiding topic was cost reduction, on every level. Tesla today laid out how they had looked to improve cell design as above, cell manufacturing, anode materials, cathode materials, and vehicle integration – Each elemental to the envisioned increase in range of up to 54% and simultaneous reductions in kWh price by 56% and the investment per GWh by 69% as mentioned above.

The last target shows that Tesla now explicitly thinks in Terawatthours when thinking of in-house battery production in the long-term. We knew that the so-called Tera expansion at Tesla’s Fremont facility had been in swing since summer.

Now it is clear, that the site is host to the new 4680 cell production and likely cathode production and the company stressed they were ramping up manufacturing of these cells already, on the pilot production line. Musk promised “It will take about a year to reach the 10 Gigawatthour capacity,” at the pilot plant. “The actual production plants will be more like 200 GWh over time,” he added.

Still, Musk also added caution when it comes to actual production (this has cost Tesla shares over 6% when voiced ahead of Battery Day) as the trick is in the machine. Said Musk: “Making the machine that makes the machine is vastly harder than the machine itself.” He would repeat this statement during the shareholder meeting multiple times.

The truth of it appeared in the machines helping to make the new electrode for the 4680 cells. The cost reduction is in large parts to come through the previously announced dry electrode technology. It does away with the wet solvent during production and applies the powder directly into the film, as Tesla explained. That is in theory. Musk admitted they had “Still a lot of work to do” on the machine they acquired from Maxwell and have revised four times since. “Right now, it’s close to working, but not with a good yield,” added the Tesla boss. He thinks the machine finally enabling large scale production will be revisions number six or seven. “That’s about three years to reach the benefits and one year to scale up fully,” Musk concluded.

Safer footing appeared in the form of the die-cast machines for the Model Y. The so-called Giga Presses, also planned for Giga Berlin, allow casting the Model Y body in only two parts and from a new alloy that does not need heat-treating or coating when cast.

This new body now also allows for new battery vehicle integration, so the battery becomes dual use as Tesla noted today: as an energy resource and structural component. Musk explained that the new cell packing directly inside the frame nearly loses the packaging that is not structural to the vehicle. This then allows Tesla to pack more cells and to move them closer to the centre of the car.

Apart from the making, there is the make-up and chemistry of parts like the anode. The company relies on silicone only Musk compared the current issues with silicon anodes with “a cookie that crumbles and gets gooey”. The company claims, however, to have gone back to the raw ingredients, to stay within the image, now mixing the raw silicon without engineering a base metal, to then stabilise the surface with a polymer coating and integrate it with a highly elastic binder. The exact composition remained unclear at this stage.

On the cathode level, the image was of a bookshelf stable enough to keep the books (ions) moving on and off. Tesla plans to use the cheaper nickel primarily and get rid of cobalt in the long-run. The latter is a move many carmakers, including Tesla, have been striving for.

At the same time, Musk put expectations into perspective, also adding that they “don’t want to be constrained by nickel availability”. Instead, there’s a three-tier approach with high nickel cells for the Semi and Cybertruck, with a 2/3 nickel and 1/3 manganese mix for “intermediate solutions,” that’s cars and the ion mix for stationary energy solutions.

And this is not too far from Tesla’s supplier reality. Panasonic, for example, combines nickel and cobalt in the current cells. Then some Chinese Model 3 features lithium iron phosphate cells (LFP) from CATL, though cobalt-free as reported. Tesla also continues to use NCM-811 cells for the long-range Model 3 in China. The batteries supplied by LG Chem comprise 80 per cent nickel and 10 per cent each cobalt and manganese.

In any case, the search for nickel had intensified in recent weeks with rumours also suggesting Musk was speaking to Canada’s Giga Metal. This approach to localising the supply chain again reappeared in the presentation.

Tesla claims to have secured a lithium reserve in Nevada that spans 10,000 acres. The company expect it to hold enough resource on a TWh scale and said it could extract the lithium from the ore using salt and putting the earth back. Details on this process were still missing last night.

The long-term bet is on recycling, in any case. Tesla said they expect recovery rates of 20%, 2.7%, and 2% for nickel, lithium, and cobalt from batteries deployed in its vehicle fleets. Again, there was not much detail and sustainability as a whole had appeared a sensitive issue at the Shareholder Meeting. The Board faced accusations of disregard of human rights across its operations in New York particularly, and across the supply chain in regards to cobalt sourcing. The motion was dismissed, and Musk would later point to the self-administered Impact Report.

In other news, Tesla took the opportunity also to unveil the Model S Plaid. The triple-motor car goes 520+ miles at 200 mph, and 0-60mph in less than 2s. That was after Elon Musk had stressed: “It’s absolutely critical that we make cars that people can people can actually afford.” He added: “Affordability is key to how we scale.”

>> Reporting from the virtual event.

3 Comments