Nissan batteries lead second life on the shop floor

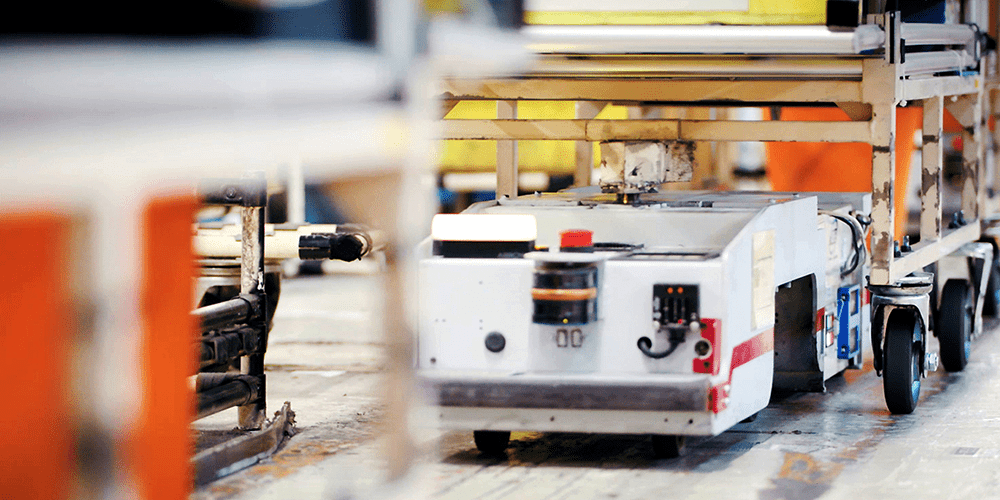

Nissan has found yet a new way of life for retired batteries from its Leaf electric model. Some now power Automated Guided Vehicles (AGV) – the driverless transport vehicles that deliver parts to the required location in the car factory.

The Automated Guide Vehicles are used to ferry components and increase plant efficiency. According to the manufacturer, “Car plants are busy places and AGVs have become indispensable. At Nissan’s Oppama plant, south of Tokyo, there are more than 700 AGVs.” More than 4,000 are globally being employed by Nissan.

Even more impressively, the human employees don’t have to take care of charging the autonomous vehicles, as “the AGVs simply stop momentarily at the charging station along their route and incrementally top up at each passing.” At current usage, the repurposed Leaf batteries are expected to stay in use for another seven to eight years, helping Nissan improve their carbon footprint, at the same time as developing their battery technology.

“Using our unique electric-driven and autonomous driving technologies to improve AGVs will bring major innovation to our factories,” says Matsumoto. “The supply of parts in factories is entering the age of electrification and automation.”

0 Comments