CATL begins licensing Cell-to-Pack tech to Hyundai Mobis

CATL is licensing its Cell-to-Pack technology, unveiled in 2019, to South Korean supplier Hyundai Mobis. In the course of the agreement, the Chinese battery manufacturer will support Hyundai Mobis in supplying CTP products not only in South Korea, but worldwide.

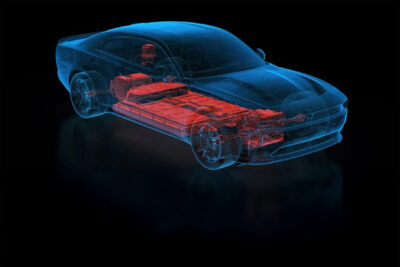

The basic idea of cell-to-pack batteries is already evident from their name: the cells are integrated directly into the battery pack. Up to now, the cells have first been installed in modules, and the modules in turn are combined to form the complete battery packs. The intermediate step of the modules is to be eliminated with the new technology. CATL had already presented its development plans based on this approach at the IAA in 2019. A few weeks later, it became public that the cells would be used for the first time in the BAIC EU5 model. An order from the Dutch commercial vehicle manufacturer VDL in 2020 also already involved batteries with a cell-to-pack design.

In a terse statement on the licensing of the technology to Hyundai Mobis, it now says that CATL will support the supplier, which is part of the Hyundai Group, not only as a licensor but also as a partner company in the introduction of the CTP technology in South Korea and worldwide. The approach “improves system energy density, simplifies manufacturing and results in cost savings”, CATL says.

It is not clear from the press release exactly for which applications Hyundai Mobis intends to apply cell-to-pack. Only this week, the company announced a skateboard platform for electric cars based on so-called e-corner modules. The latter integrate the steering, braking, suspension and electric drive systems in one wheel, which is supposed to make the platform particularly flexible with regard to the wheelbase and the wheels themselves rotatable by 90 degrees. It is quite conceivable that CATL’s cell-to-pack battery approach is also intended for the platform announced for 2023.

In the official announcement, CATL and Hyundai Mobis leave it at general formulations: They will work together to develop higher-quality products for the global electric vehicle market, it says. CATL describes the partnership as a new form of international technology cooperation in the industry, thanks to which it will be possible to promote the spread of its own innovative battery technology worldwide.

CATL already published key data on its CTP technology in 2019. According to this, the approach is to increase the mass-related energy density by 10 to 15 per cent and the volume-related utilisation efficiency by 15 to 20 per cent. This means that more energy can be stored in the same battery space, while the battery also becomes lighter. It should also require 40 per cent fewer components.

In terms of a battery pack, these improvements mean an energy density of 200 Wh/kg instead of the current 180 Wh/kg. At the battery cell level, CATL said it had already achieved an energy density of 240 Wh/kg in 2019. At the time, the company cited an energy density of 350 Wh/kg as its target for 2024 – although it did not specify whether this was the energy density of a battery pack or a battery cell.

In the meantime, the Chinese battery cell manufacturer announced in August 2020 that it intends to push the “cell-to-pack” technology one step further – in the form of an approach called ‘cell-to-chassis‘. The battery cells are to be integrated directly into the chassis of electric cars, which means that not only the modules but also the packs could be dispensed with.

0 Comments