StoreDot hits the 1,000-cycle mark with production-ready pouch cells

Israeli battery developer StoreDot has reached an important milestone with its fast-charging silicon-dominated battery cells. The battery maker says its Pouch cells in a production-ready format have now passed the 1,000-cycle mark.

++ This article has been updated. Kindly continue reading below. ++

The defining phrase “production-ready format” is important here because StoreDot already reached 1,200 cycles for silicon-dominated battery cells in March – but at that time, these were in a specially developed test form factor. The current cells, which are said to have an energy density of 300 Wh/kg or 700 Wh/l, are pouch cells in an automotive-ready format and can now be delivered to StoreDot’s global automotive partners for intensive field testing. These include VinFast, Volvo and Polestar. Daimler also invested in StoreDot in 2017.

The test cells that have now been delivered are not expected to be the end of the development: StoreDot has said that it expects further improvements by the end of the year.

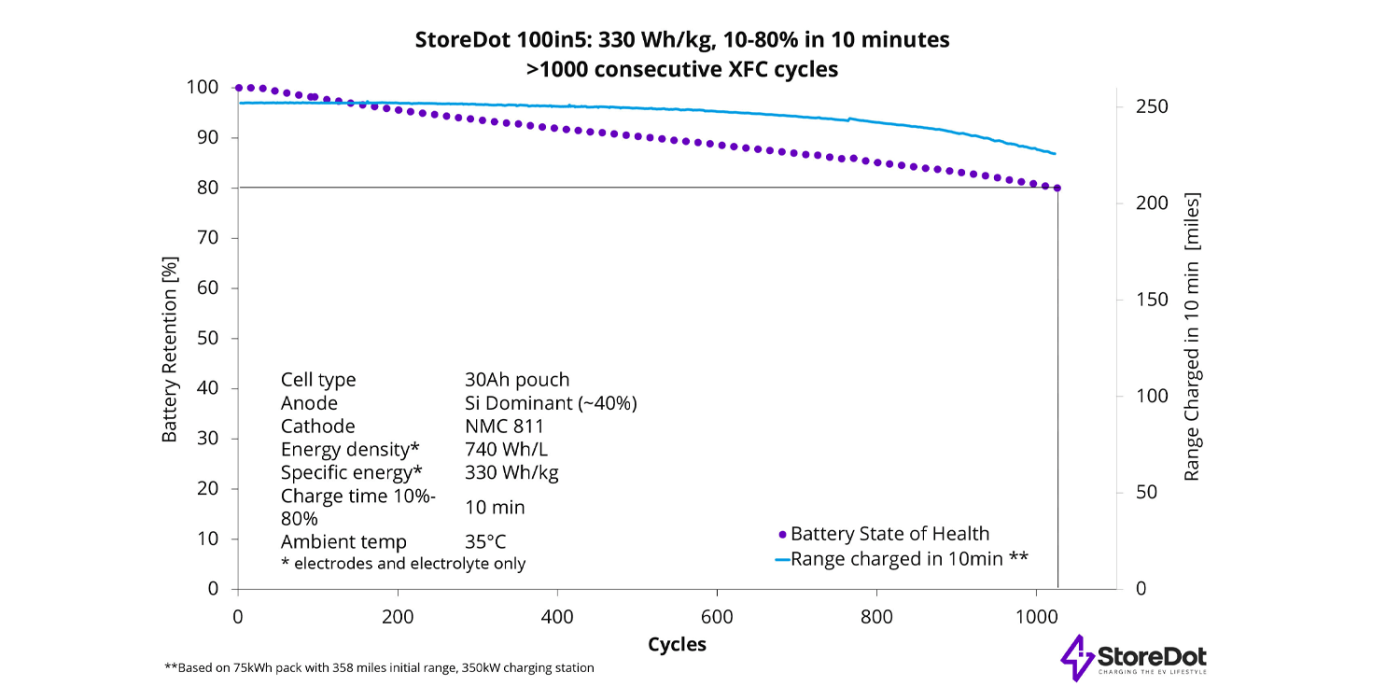

The cells are to offer the “100in5” performance targeted by StoreDot, which means that it should be possible to recharge for 100 miles in five minutes. For the 1,000 cycles, the battery was charged from ten to 80 per cent within ten minutes. Before the next charge, it was discharged for one hour. After 1,000 pure fast-charge cycles, the capacity was still at 80 per cent of the initial value. According to StoreDot, there was “no noticeable degradation” within the first 600 cycles.

The cell itself is a 30 Ah pouch cell. The anode has up to 40 per cent silicon, and the cathode holds NMC811 chemistry. The temperature in the laboratory set-up was 35 degrees Celsius.

Yaron Fein, StoreDot Vice President R&D says: “Our product performance goal for 2022 was to reach 1000 cycles of consecutive extreme fast charging of 10 to 80 per cent in ten minutes, with an energy density of at least 300Wh/Kg.” He explains that the development team have not only “achieved our target but have also exceeded it – and we already have in our lab’s enhanced formulation that allows us to show further improved performance.”

Fein explains that when a lithium battery is charged and discharged once, it is called a cycle, and typically lithium battery capacity degrades quickly in fast charging cycles. “Our silicon-dominant chemistry is different, allowing EV battery cells to charge for more than 1000 cycles before degrading the battery to 80% of its original capacity,” he says.

In March this year, StoreDot unveiled its “100inX” technology roadmap. The “100in5” cells are expected to enter mass production in 2024 (both as pouch cells and in the 4680 round cell format), while the “100in2” technology is expected to enter mass production in ten years.

Update 08 December 2022

The Israeli battery developer StoreDot has now had the performance of its fast-charging silicon-dominated battery cells evaluated by the independent laboratory Shmuel De-Leon Energy. These are the 30 Ah pouch cells for electric cars presented in the article above. According to StoreDot, the test results determined by the laboratory confirm an energy density of 300 Wh/kg and 1,000 consecutive extremely fast charging cycles – the values that the developer had initially stated.

Despite the numerous live demonstrations in the past months, the test by independent experts was an important step, the company says. “It is particularly gratifying to have the commercialization validity and superior performance of StoreDot’s XFC and high energy technology verified by leading experts in the field,” said StoreDot CEO Doron Myersdorf. “In addition, our technology continues to be trialed in the real-world by our leading automotive partners.”

prnewswire.com, prnewswire.com (update)

0 Comments