Leclanché reports breakthrough in environmentally-friendly battery production

Swiss battery manufacturer Leclanché says it has made a breakthrough in the environmentally friendly production of modern G/NMCA cells. Leclanché is able to reduce the cobalt content in NMCA electrodes from 20 to five per cent in an environmentally friendly water-based process.

In the process, Leclanché completely eliminates the use of the highly toxic organic solvents (NMP, short for N-methylpyrrolidone) that are otherwise common in the production process. According to Leclanché, the new G/NMCA cells offer a 20 per cent higher energy density compared to conventional NMC cells – with the same size, weight and very good performance. The “G” stands for the graphite in the anode, NMCA for a cathode based on nickel-manganese-cobalt-aluminium oxide.

One thing is clear: NMCA cathodes based on water-based binders are easier to dispose of and recyclable. The newly developed G/NMCA cell is said to have a nickel content of around 90 per cent, which increases the energy density and allows the cobalt content to be significantly reduced by 15 per cent. At the same time, according to the company, it offers a longer service life, high cycle stability and good chargeability.

Thanks to the high volume density and high cycle stability, the new cells are said to be particularly well suited for “electric cars as well as heavy-duty applications such as ships, buses and trucks” . Leclanché’s new G/NMCA cells are expected to be available on the market in 2024.

However, the company does not specify the exact composition. For so-called NMC811 cells, which are already used in today’s electric vehicles, the mixing ratio is 8 to 1 to 1 – already with ten per cent cobalt instead of 20 per cent, which Leclanché states as the initial value. However, the result of five per cent and no NMP would still be a significant improvement.

Company representatives also emphasise in the release, however, that the real breakthrough lies in the production that is now possible. “With the water-based production of the high-capacity NMCA cathodes, we have reached a decisive milestone in lithium-ion technology,” says Hilmi Buqa, Vice President R&D at Leclanché. “Until now, producing them using environmentally friendly processes was considered impossible. But, now we have mastered the process.”

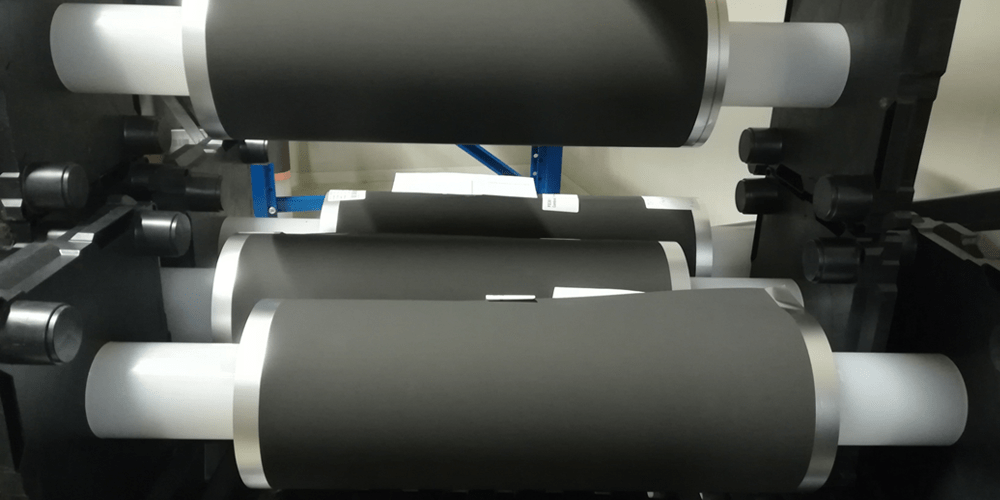

Leclanché has been using aqueous binders in its battery production for many years. Among other things, because the previous production processes based on these binders did not allow for such high energy densities as were required for automotive use, Leclanché batteries have so far mainly been used in commercial vehicles and in the shipping industry for hybrid ferries or electric ships.

By the way, with the water-based process, Leclanché can already dispense with energy-intensive processes for drying, flashing off and recycling the solvents. Energy consumption is therefore said to be ten to 30 per cent lower.

The large-format cells come from German production at the Willstätt site in Baden-Württemberg, while Leclanché’s module production takes place on a state-of-the-art automated assembly line at the company’s headquarters in Yverdon, Switzerland.