Chalmers researchers reveal 500 kW induction technology

Researchers at Chalmers University in Sweden have developed an induction technology that can reach nearly 100% efficiency and charges with 500 kW – effectively putting it on par with wired solutions. The team says the system was so complete they could soon present it to the industry, especially since they smartly combine existing components.

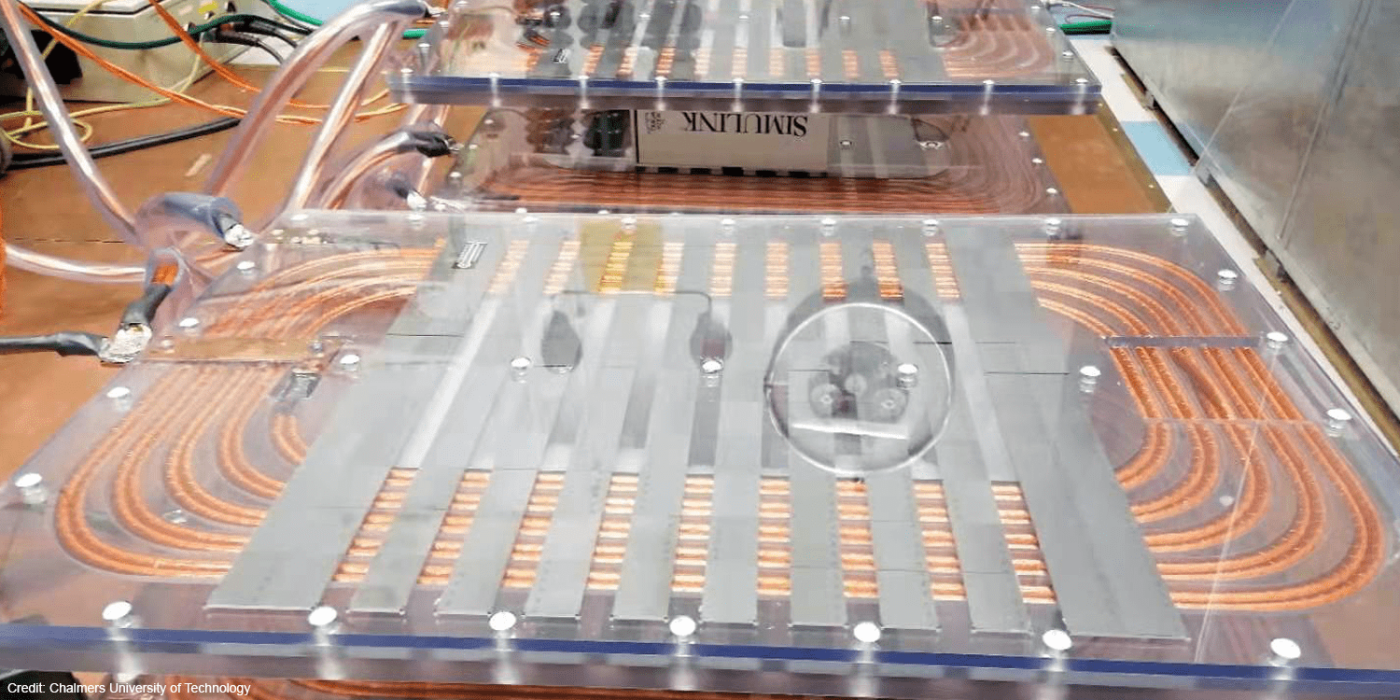

First to the current spec – the team at Chalmers specifies 98% efficiency and DC transfers of 500 kW per two square meters with a 15 cm air gap between the ground pad and the onboard pad. This corresponds to a loss of a mere ten kilowatts.

The researchers are aware that numbers must be considered carefully. Still, Professor Yujing Liu, who is in charge of the project at the Department of Electrical Engineering at Chalmers, concedes they were “probably among the best in the world in terms of efficiency in this power class, between 150 and 500 kW”.

Moreover, the trick to achieve these results and the reason why the technology is near-ready for commercialisation is that the Chalmers team uses existing – though still fairly novel – components all geared to carry and withstand higher frequencies needed to achieve high charging powers.

Professor Yujing Liu, adds that it was the “rapid development” of these components and materials in recent years that has opened new possibilities.

“A key factor is that we now have access to high-power semiconductors based on silicon carbide, so-called SiC components,” Yujing Liu explains. While these have only been on the market for a few years, “they allow us to use higher voltage, higher temperature, and much higher switching frequency, compared to classic, silicon-based components,” so the professor.

The frequency of the magnetic field is crucial since that sets the limit to how much power can be transferred between two coils of a given size. Previous wireless charging systems usually utilise frequencies of around 20 kHz, much like a normal stove top. This left them “bulky,” says Yujing Liu. His team, however, works with four times higher frequencies, and this step to 80 kHz was making induction suddenly attractive, so the professor.

The researchers appear in close contact with two companies based in the US and Germany which Yujing Liu considers leading in SiC technology. “With them, rapid product development takes place towards even higher currents, voltages, and effects.” He calls these ever-improving components “enablers” with a wide range of applications. We, of course, also know those from inside electric vehicles.

For induction charging, as proposed by Chalmers, there is another component reliant on frequency. The copper wires in the coils send out and receive the oscillating magnetic field that forms the actual bridge for the energy flow. Again, the goal is to use as high a frequency as possible, and this requires better coils.

The Chalmers team now uses braided ‘copper ropes’, consisting of up to 10,000 copper fibres, each only between 70 and 100 micrometres thick, much like a strand of hair.

Such braids, of so-called litz wire, have also only been commercially available in the very last few years and are able to take higher frequencies.

Yujing Liu mentions a third example of technologies smartly combined when speaking to Sandra Tavakoli at Chalmers. The team uses a new type of capacitor to add the reactive power that is a prerequisite for the coil to be able to build up a sufficiently powerful magnetic field.

Powerful enough to charge electric buses and ferries, for example, but not necessarily cars. Yujing drives an electric car but says he did not see any use of induction charging. “I drive home, plug in… it’s no problem.”

As for the efficiency of nearly 100 per cent, the professor is aware that “that figure may not mean much if you do not carefully define what is measured,” especially since charging electric vehicles contains several conversion steps – between direct current and alternating current and between different voltage levels.

“But you can also put it this way: Losses occur whether you use ordinary, conductive charging or charge with the help of induction. The efficiency we have now achieved means that the losses in inductive charging can be almost as low as with a conductive charging system. The difference is so small that in practice it is negligible, it is about one or two per cent”.

The next step will be to bring the induction system into industrial use. The researchers mention ferries or lorries that could be wirelessly charged without human or robotic help in future.

0 Comments