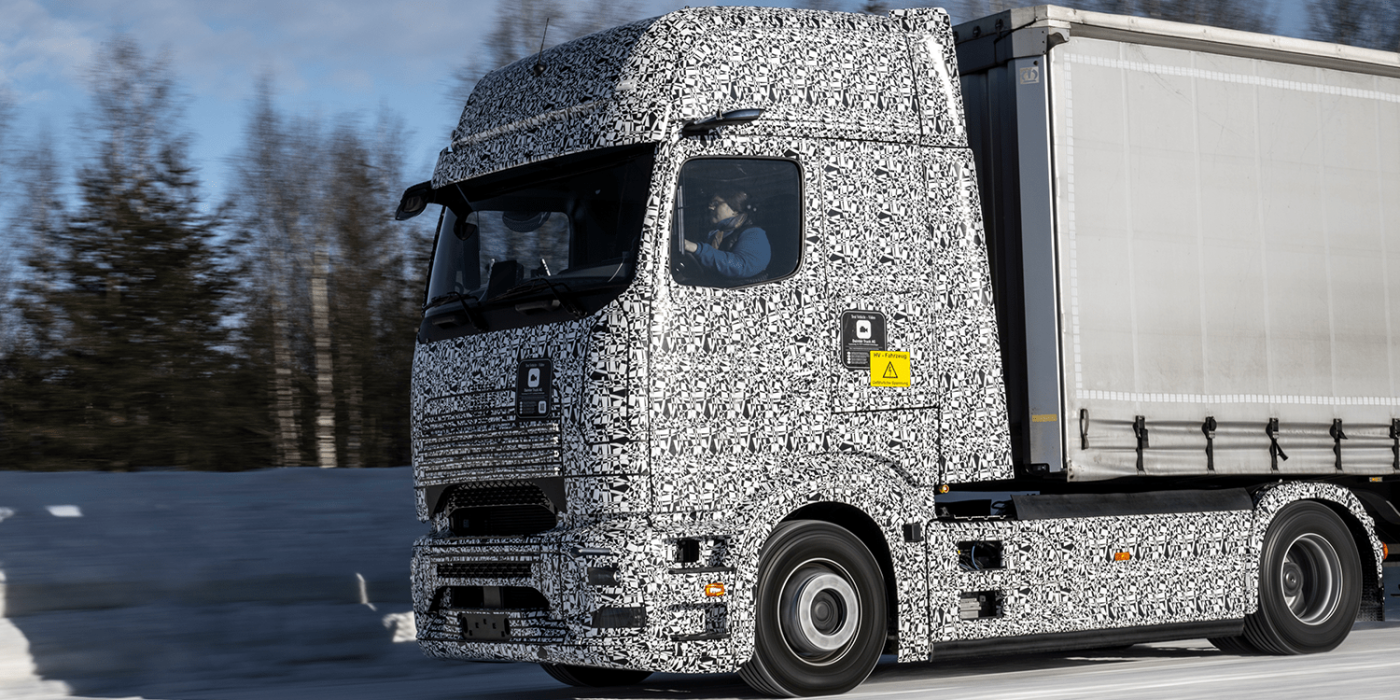

Daimler Truck tests electric trucks in the freezing cold in Finland

While many certainly wish for spring at this point, winter is an important season for Daimler Truck. To put its eActros 300 electric truck and the recently introduced LongHaul variant through their paces even in icy and cold conditions, the fleet headed some 3,000 kilometres north.

The tests themselves are nothing special for Mercedes-Benz. Engineers have been heading up to Rovaniemi, Finland, for vehicle tests for years. But this was the first time the manufacturer had “a large fleet of electric vehicles,” explained Christof Weber, Head of Global Testing Daimler Truck, at a digital roundtable. The goal was to see whether the truck delivered what it promised – at an outside temperature of minus 25 degrees Celsius. “Let me say this much up front: we were pleasantly surprised,” says Weber. “That’s exactly what it did.”

According to Weber, engineers paid particular attention to recuperation during testing. After all, he says, that is one key difference from the internal combustion vehicle. “It’s all very exciting, of course, because I can recover energy that way and extend my range,” he says. Weber says some kind of braking strategy is needed to take full advantage of recuperation. “How do I balance recuperation and braking in general when I’m driving a tractor-trailer, and the tractor-trailer also has to brake the weight of the trailers? It’s all a bit different than what we know from combustion vehicles.”

“Now it gets really interesting,” he adds, “recuperation is like a retarder regarding braking capability. And, of course, that all has to be coordinated with the new assistance systems.” With the Active Sideguard Assist, for example. It warns the driver of moving cyclists or pedestrians next to the vehicle and can initiate emergency braking. But it also has to work with systems designed to assist drivers in changing weather conditions.

These were also put under the microscope in Finland. Because, says Weber, assistance systems should give as few error warnings as possible. That means they must be able to distinguish whether a road is already icy or just wet – and that in changing light conditions. If the systems provide optimum support for the driver, the latter would be much more relaxed when reaching his destination, even after a long journey. Weber says he experienced this, not least on the trip to Finland.

Driving with strategy

On the Arctic Circle, heating in the driver’s cab is essential. Although the eActros can be heated more quickly than the diesel version, the energy comes from the battery and ultimately reduces the truck’s range. That is why Daimler Truck recommends so-called pre-conditioning, i.e. heating the truck while it is plugged in at a charging station. Mercedes did not have exact data available, but Weber explained that the range would drop significantly without pre-conditioning.

At temperatures of around minus ten degrees Celsius, the vehicle is immediately charged at the charging station while the heating is turned up. In this case, the expert says the battery also heats up more or less by itself. It is more critical at temperatures below minus 20 degrees. In that case, the battery must first be brought up to temperature at the charging station before charging starts with a slight delay.

In order to model summer and winter throughout the year, the manufacturer has set up a new testing facility at its site in Wörth, Germany. The cold chamber can be cooled to minus 40 and heated to up to plus 70 degrees Celsius. That way, the manufacturer can test, for example, how the battery behaves at these temperatures and how charging works best.

But there would soon be technical solutions so that energy consumption for heating, etc., would not impact the range. Weber did not want to say exactly which ones at this point, only that “you should be curious. In the next few years, there will be a lot, a lot of things coming from us that have not been seen so far.”

“We’d like to see more charging points”

The trucks covered around 2,800 kilometres to Rovaniemi. The eActros LongHaul, with series readiness planned for 2024, was loaded on the back of a conventionally powered lorry because it is not yet road-legal. But the distribution vehicles, the eActros 300, drove there independently and thus had to make one or two charging stops.

The battery-electric tractor unit can be charged with up to 160 kW. At a DC fast charging station with 400 A charging current, it takes just over an hour to charge the three batteries from 20 to 80 per cent. Series production of the eActros as a tractor unit is scheduled for the second half of 2023. The LongHaul will sport a 600 kWh battery and close to 600 kW peak power.

Charging took place at existing charging points, i.e. at truck stops and pillars reserved for passenger cars. “Today, we don’t have that many truck-only charging stations, but you can also charge at a car charging station. But then you need two or three parking spaces,” Weber says.

“Of course, we’d like to see more charging points,” the Daimler truck manager continues. The manufacturer is working with Volvo and Traton to install more charging stations at highway rest stops. The joint venture Milance launched last year and wants to build a high-performance charging network for heavy trucks and coaches in Europe. In the future, the network density should enable professional drivers to fully recharge their trucks during their legally required 45-minute break. According to Milance, the initial focus will be on expanding the charging infrastructure in Germany, the Netherlands, France, Belgium, Spain, Italy, Norway and Sweden.

But back to Finland: According to Weber, the average charging power at the stations was 150 kW, so the trucks sometimes had to take a break of two to three hours there. Overall, the EV fleet took around one to one and a half days longer to cover the distance than conventionally powered vehicles.

But, as Weber repeatedly pointed out, the eActros 300 is a distribution vehicle that won’t have to cover 500 kilometres in one go. That is why this experience is negligible, he says. The eActros LongHaul, designed for long distances, can charge faster, especially since there will be more charging points with more power reserved for trucks in the future. “And then the goal is to charge the battery to 80 per cent within 30 minutes,” says Weber. But even now, he says, “charging as a basic task has been possible.”

0 Comments